- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Innovative Solutions for Enhancing Safety on Helideck Netting Systems

Understanding Helideck Netting A Comprehensive Overview

Helideck netting is an essential safety feature utilized in the aviation and maritime industries, particularly for offshore platforms where helicopters are integral for transportation and logistics. This specialized netting system plays a critical role in ensuring the safety of both personnel and equipment during aircraft landings and takeoffs. As the demand for offshore operations continues to rise, so does the emphasis on enhancing safety standards and protocols, making helideck netting more relevant than ever.

The Importance of Helideck Netting

The primary purpose of helideck netting is to provide a robust barrier that minimizes risks associated with helicopter operations. This netting system is designed to catch and contain any falling objects that might pose a hazard to the helicopter during its approach or landing phase. Additionally, it prevents loose equipment or tools from being inadvertently blown off the helideck due to strong winds, thus further safeguarding both workers on the helideck and the aircraft.

Another crucial aspect of helideck netting is its ability to enhance the overall structural integrity of the helideck

. By creating a secure environment, it not only reduces the chances of accidents but also maintains the operational efficiency of the platform. When equipment and materials are safely secured, the focus can shift towards more critical operational tasks, enhancing productivity.Design and Standards

Helideck netting is constructed from high-strength materials such as nylon, polyester, or other synthetic fibers designed for durability and resilience. These materials can withstand harsh environmental conditions, including extreme temperatures, high winds, and salt exposure, which are common in offshore settings.

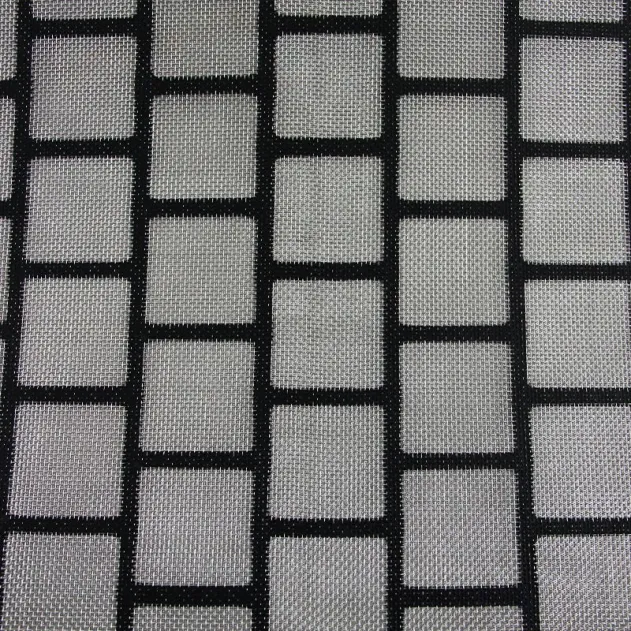

helideck netting

The design of the netting system adheres to stringent international safety standards, including those set by the International Civil Aviation Organization (ICAO) and the Department of Energy's guidelines in various countries. These regulations ensure that the netting can absorb impacts effectively, maintaining its effectiveness even over prolonged use.

Installation and Maintenance

Correct installation of helideck netting is critical for its efficacy. Professional teams are often tasked with ensuring that the netting is securely fastened and positioned correctly to provide optimal protection. Regular inspections and maintenance of the helideck and its netting are equally essential. This includes checking for wear and tear, as well as ensuring that the netting remains intact without any gaps or damages.

Moreover, maintenance procedures should align with the operational schedule of the helideck to minimize downtime. Routine checks, ideally conducted before and after each helicopter operation, can help identify potential issues before they escalate into serious safety concerns.

Future Trends and Innovations

As technology advances, so does the development of helideck netting systems. Innovations, such as smart materials and sensors integrated into the netting, have the potential to further enhance safety measures. These advancements can provide real-time data on netting integrity or alert personnel to potential hazards, creating smarter and more responsive safety environments.

In conclusion, helideck netting serves as a vital safeguard in the offshore aviation sector. As operations become increasingly complex and safety demands rise, the significance of robust netting systems cannot be overstated. By prioritizing proper design, installation, and maintenance, stakeholders can ensure that helideck netting continues to protect both personnel and equipment, ultimately contributing to safer and more efficient operations in the bustling offshore industry. The future of helideck netting is bright, with innovations promising to elevate safety standards to new heights.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025