- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

helideck nets

Understanding Helideck Nets Essential Safety Features for Helicopter Operations

Helideck nets play a critical role in ensuring the safety and efficiency of helicopter operations, particularly in offshore environments, such as oil platforms and other maritime installations. These nets serve as a vital safety measure, preventing helicopters from sliding off the helideck during landings and takeoffs while also providing additional support in emergency scenarios.

The Functionality of Helideck Nets

The primary function of helideck nets is to enhance safety by capturing any potential falls of helicopters. Helicopter landings, particularly in harsh weather conditions, can be unstable, and a helideck net acts as a protective barrier that catches the aircraft if it slips from the landing area. This barrier is particularly crucial in offshore operations where the risk of helicopter mishaps can be exacerbated by wind, waves, and limited visibility.

Furthermore, helideck nets serve as a crucial safety feature during helicopter operations involving passenger transport, medical emergencies, or cargo deliveries. By reducing the risk of accidents, helideck nets significantly contribute to the overall safety of crew members and passengers, assuring that safety protocols are maintained in high-stakes situations.

Construction and Materials

The construction of helideck nets is vital for their effectiveness. Typically, these nets are made from high-strength synthetic materials that provide durability and resilience against harsh environmental conditions, such as saltwater corrosion and strong winds. The design involves a mesh structure that absorbs impact and distributes the weight of the helicopter evenly across the surface of the helideck, thereby minimizing damage both to the aircraft and the installation.

Design standards for helideck nets are guided by international regulations, including those set by the International Maritime Organization (IMO) and the Civil Aviation Authority

. Ensuring compliance with these standards is crucial for operational safety and can impact insurance and liability claims in the event of an accident.helideck nets

Maintenance and Inspection

Regular maintenance and inspection of helideck nets are critical for operational safety. Given their exposure to harsh environmental conditions, these nets are subject to wear and tear. Routine inspections should include checking for frays, loose connections, and overall structural integrity. Any signs of degradation need to be addressed promptly to maintain the net's reliability in emergencies.

Operators often implement a maintenance schedule that aligns with their helicopter operations, ensuring that the nets are in optimal condition before each flight. Training crew members to recognize potential safety issues is also an essential part of the maintenance process, helping to create a culture of safety within the organization.

Future Developments

As technology advances, so too does the development of helideck nets. Innovations in materials and design are continually being explored to enhance the safety features of these nets. For example, integrating sensors into helideck nets could provide real-time data on their condition, alerting operators to any necessary maintenance before a situation arises.

Additionally, enhanced training simulations for pilots and crew could improve preparedness in emergency scenarios, increasing the overall safety and efficiency of helicopter operations.

Conclusion

Helideck nets are not just a regulatory requirement but a crucial safety element for helicopter operations, particularly in offshore sectors. Their ability to prevent helicopter accidents and enhance overall safety cannot be overstated. As the industry continues to evolve, maintaining and improving helideck net standards will be essential in ensuring the safety of all helicopter operations. Understanding the importance of these safety features is vital for all stakeholders involved in this high-risk domain.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

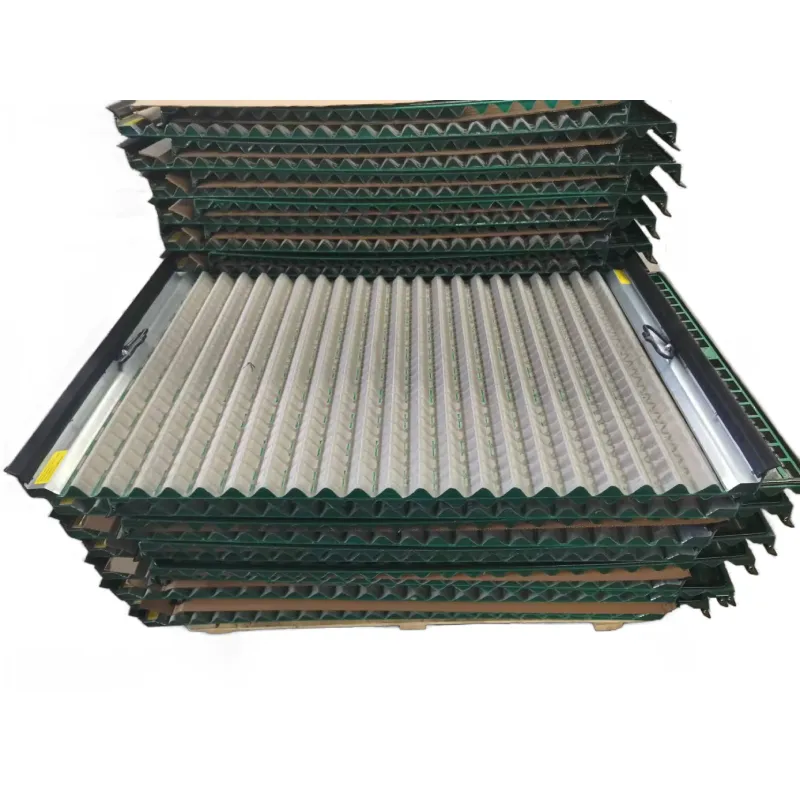

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025