- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

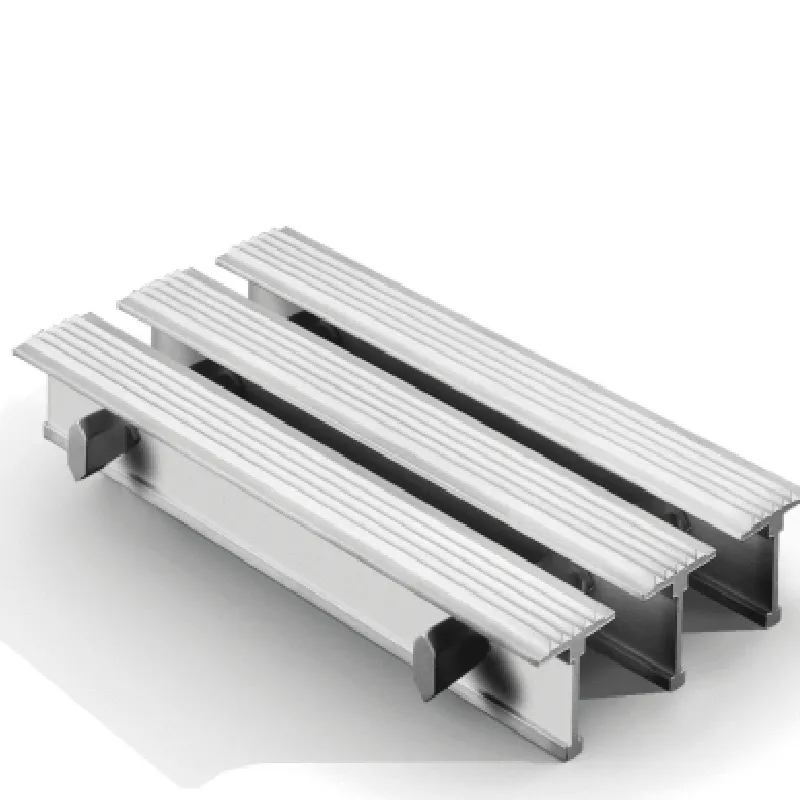

heavy duty steel grating

Heavy Duty Steel Grating A Comprehensive Overview

Heavy duty steel grating is a versatile and robust material utilized in various industries, from construction and manufacturing to transportation and sewage management. Its unique design and mechanical properties make it an ideal choice for applications where strength and durability are paramount. This article explores the characteristics, advantages, applications, and maintenance of heavy duty steel grating.

Characteristics

Heavy duty steel grating is made from high-quality steel, often hot-rolled or cold-rolled, providing exceptional load-bearing capabilities. The grating is typically designed with larger openings and thicker bars than standard grating, allowing it to withstand heavy traffic and substantial loads. Common configurations include welded and swage-locked types, offering different advantages depending on the specific application.

The surface of heavy duty steel grating can be treated for enhanced safety and functionality. Options such as slip-resistant coatings, galvanized finishes, and powder coating are available to improve corrosion resistance and prevent slips and falls. This makes steel grating suitable for outdoor use where exposure to moisture and harsh weather conditions is a factor.

Advantages

One of the primary advantages of heavy duty steel grating is its strength. It can support significant weight, making it a preferred choice for bridges, walkways, platforms, and industrial flooring. Additionally, its open design promotes drainage and air circulation, reducing the buildup of water and debris that can lead to safety hazards.

Another notable benefit is its longevity. Steel grating is highly resistant to mechanical wear and corrosion when appropriately treated, which translates to lower maintenance costs over time. Furthermore, its lightweight nature allows for easier handling and installation compared to solid alternatives, thereby reducing labor costs.

heavy duty steel grating

Applications

Heavy duty steel grating finds its applications in a wide array of sectors. In the construction industry, it is used for durable flooring in factories, warehouses, and commercial buildings. The oil and gas industry employs steel grating for safety in refineries and platforms, where it must withstand harsh environmental conditions.

Municipalities utilize heavy duty steel grating for trench covers, drainage systems, and pedestrian walkways. The transportation sector also benefits from this material, particularly in the design of bridges and roadways where heavy vehicular loads are common.

Maintenance

While heavy duty steel grating is designed for durability, regular maintenance is essential to ensure its longevity. Routine inspections should be conducted to check for signs of wear, corrosion, or damage. Any issues should be addressed promptly to prevent larger problems down the line.

Cleaning is also critical, especially in environments where oil, chemicals, or other substances may accumulate on the surface. Utilizing pressure washers or industrial cleaning solutions can help maintain the grating’s effectiveness and appearance.

Conclusion

Heavy duty steel grating is an essential material for various industrial and commercial applications. Its strength, durability, and resistance to environmental challenges make it a reliable choice for heavy-duty performance. With proper care and maintenance, steel grating can provide long-lasting service, contributing positively to safety and efficiency in countless applications. As industries continue to evolve, the demand for high-quality heavy duty steel grating will likely remain strong, emphasizing its importance in modern infrastructure and construction.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025