- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

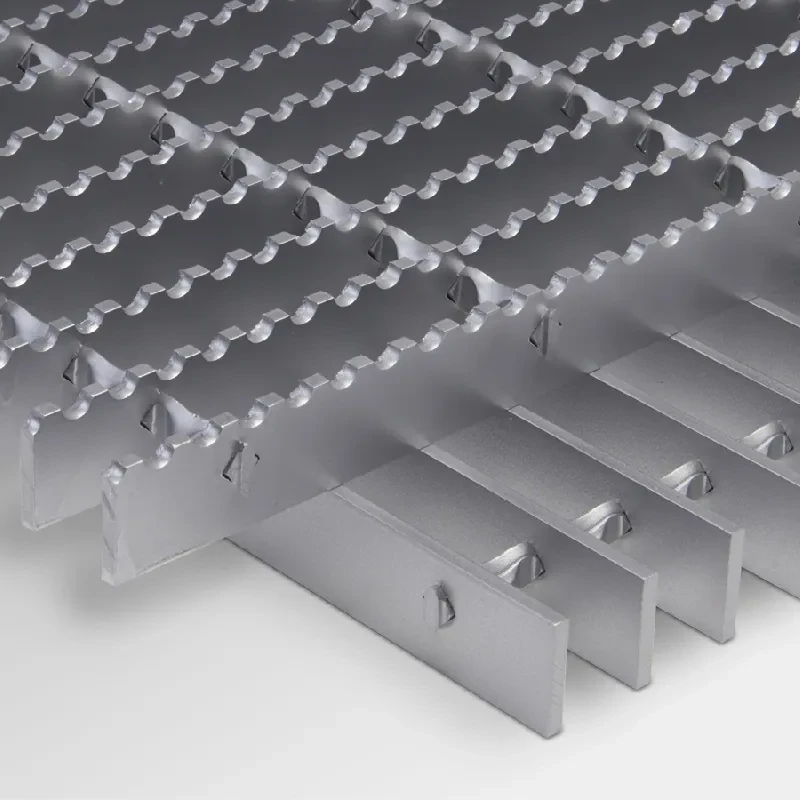

heavy duty steel bar grating

Heavy Duty Steel Bar Grating A Comprehensive Overview

Heavy duty steel bar grating is an essential material widely used across various industries for its strength, durability, and versatility. This type of grating is composed of parallel steel bars, typically welded or forged together, to create a robust surface that can withstand significant loads. The design of heavy duty steel bar grating makes it an ideal choice for applications that require strong support and resilience under heavy traffic, such as in industrial facilities, pedestrian walkways, and even parking garages.

Characteristics and Benefits

One of the primary characteristics of heavy duty steel bar grating is its ability to support heavy loads without compromising structural integrity. The spacing and thickness of the bars can be customized based on specific load requirements, ensuring that the grating meets the precise needs of any project. This customizability makes heavy duty steel bar grating suitable for a variety of applications, from vehicular traffic areas to equipment access points.

Moreover, the open design of steel bar grating allows for efficient drainage of liquids and debris, reducing the risk of hazardous slip-and-fall incidents. This permeability also facilitates airflow and light penetration, making it a favored choice for platforms and walkways that require visibility and ventilation.

Another significant benefit of heavy duty steel bar grating is its resistance to corrosion and environmental degradation, especially when treated with protective coatings like galvanization. Galvanized steel grating can withstand harsh weather conditions, chemical exposure, and UV radiation without losing its structural properties, making it ideal for outdoor applications. This durability translates into lower maintenance costs over time compared to alternatives like plastic or wooden grating.

Common Applications

Heavy duty steel bar grating is utilized in a wide range of industries, including manufacturing, automotive, construction, and food processing. In manufacturing, it is often employed for floor grates and platforms that support heavy machinery and equipment. The automotive industry utilizes steel bar grating in car wash facilities, where water drainage is crucial.

heavy duty steel bar grating

In construction, heavy duty grating serves as a durable flooring solution for scaffolding, walkways, and maintenance platforms. Its load-bearing capacity and slip-resistant surface help ensure worker safety at height. Similarly, in the food processing sector, steel grating is commonly found in areas that require sanitary conditions, as it can be easily cleaned and sanitized without retaining contaminants.

Additionally, heavy duty bar grating is used in the oil and gas industry for offshore platforms, refineries, and chemical plants, where it is essential to have a safe and robust support structure.

Installation and Maintenance

The installation of heavy duty steel bar grating is typically straightforward, as it can be secured to various substrates using bolts, screws, or welding, depending on project specifications. Custom-cut grating sections can be tailored to fit complex layouts, ensuring a secure fit in any environment.

Maintenance of steel bar grating involves regular inspections to identify signs of wear or corrosion. For galvanized grating, periodic inspections and cleaning are sufficient to maintain its performance and extend its lifespan. Any damages, such as loose bars or significant corrosion, should be addressed promptly to prevent accidents and ensure continued safety.

Conclusion

In summary, heavy duty steel bar grating is a reliable, highly functional solution that meets the demanding requirements of various industrial and commercial applications. Its strength, durability, and customizable nature make it a preferred choice for engineers and architects alike. As industries continue to prioritize safety and efficiency, heavy duty steel bar grating will undoubtedly remain an integral part of infrastructure development. By investing in quality steel grating, organizations can enhance operational safety, reduce maintenance costs, and ultimately contribute to more sustainable practices in construction and manufacturing. Whether for new projects or renovations, heavy duty steel bar grating stands as a testament to effective design and engineering solutions that cater to modern demands.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025