- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

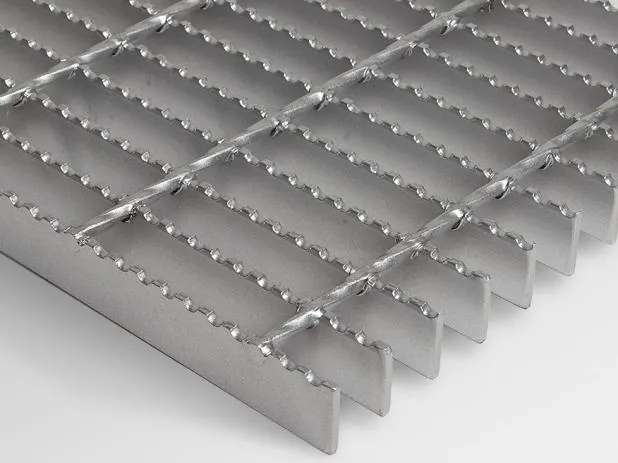

Durable Mild Steel Grating for Heavy Duty Applications and Industrial Use

Heavy Duty Mild Steel Grating An Overview

In the world of industrial applications, heavy duty mild steel grating has become an essential component, offering structural support and safety in various environments. This article will delve into the benefits, applications, and manufacturing process of heavy duty mild steel grating, explaining why it is a preferred choice in numerous industries.

What is Heavy Duty Mild Steel Grating?

Heavy duty mild steel grating is a type of flooring and walkway system made from flat steel bars, welded or forged together to create a grid-like structure. It is designed to support heavy loads, making it ideal for industrial environments where strength and durability are paramount. Commonly fabricated from mild steel, this grating exhibits excellent strength-to-weight ratios, allowing it to withstand considerable stress while maintaining manageable weight.

Key Benefits

1. Durability One of the primary advantages of heavy duty mild steel grating is its durability. Mild steel is known for its toughness, providing an extended lifespan even under harsh conditions. It can resist the wear and tear associated with heavy foot traffic and machinery, making it a cost-effective solution over time.

2. Versatility Heavy duty grating can be custom-engineered to fit various applications. It comes in a variety of sizes, shapes, and load classifications, allowing for adaptability in different environments. Whether used in walkways, platforms, or as industrial flooring, its versatility is unrivaled.

3. Safety The open design of steel grating provides excellent drainage and airflow while reducing the risk of slips and falls. This feature is especially important in environments where liquids may be present, such as in food processing or chemical plants. Furthermore, its strength ensures that it can bear heavy equipment without compromising safety.

4. Cost-effective While the initial investment might seem higher than other flooring options, the long-term savings due to durability and low maintenance costs make heavy duty mild steel grating an economically sound choice.

5. Eco-friendly Steel is infinitely recyclable, making it an environmentally friendly option. At the end of its lifespan, heavy duty mild steel grating can be recycled, reducing waste and promoting sustainability.

Applications

Heavy duty mild steel grating is utilized in various sectors, including

- Industrial Facilities Factories and warehouses often employ steel grating for walkways, platforms, and equipment access points. Its ability to handle heavy loads is crucial in these settings.

heavy duty mild steel grating

- Construction In construction, steel grating serves as scaffolding and support systems, ensuring worker safety while providing stability for building structures

.- Transport and Infrastructure Roadside drainage systems and bridge walkways frequently use steel grating due to its strength and ability to withstand environmental wear.

- Mining and Oil & Gas Harsh conditions in these industries demand robust solutions, and heavy duty mild steel grating meets these requirements effectively.

- Marine Applications With exposure to corrosive saltwater, marine industries often opt for steel grating, sometimes with additional coatings for enhanced corrosion resistance.

Manufacturing Process

The production of heavy duty mild steel grating typically involves several steps

1. Material Selection Mild steel is chosen for its balance of strength, weldability, and cost-effectiveness.

2. Cutting and Shaping Steel bars are cut to specified dimensions and shaped into a grid format.

3. Welding The bars are welded together at intersections, ensuring structural integrity and load-bearing capacity.

4. Finishing Depending on the intended application, finishing processes such as galvanization or coating may be applied to enhance corrosion resistance and durability.

5. Quality Control Rigorous testing is conducted to ensure compliance with safety standards and load ratings before the product is delivered.

Conclusion

Heavy duty mild steel grating is an indispensable part of modern industrial infrastructure. Its remarkable durability, safety features, and adaptability make it suitable for a myriad of applications, from factories to marine environments. By understanding the benefits and manufacturing processes of mild steel grating, industries can make informed choices that prioritize safety, efficiency, and longevity, ultimately contributing to a more resilient operational framework.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025