- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

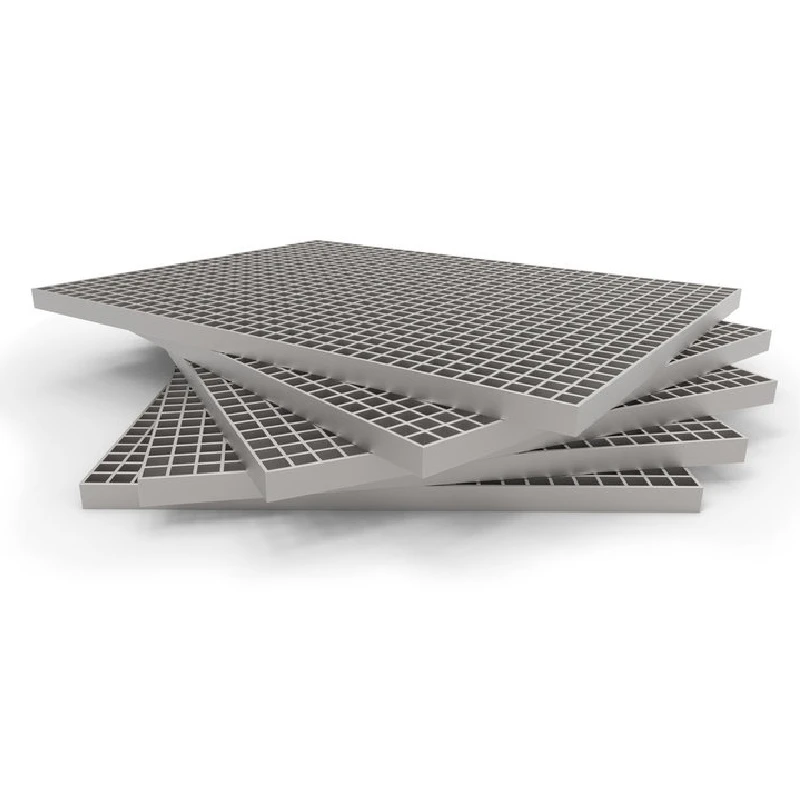

heavy duty gratings

Heavy Duty Gratings An Essential Solution for Industrial Applications

Heavy duty gratings are becoming increasingly essential in various industries due to their robustness, versatility, and cost-effectiveness. Commonly utilized in construction, manufacturing, and infrastructure, these gratings provide a reliable solution for supporting heavy loads while ensuring safe passage for pedestrians and vehicles. In this article, we will explore the characteristics, applications, and advantages of heavy duty gratings.

Characteristics of Heavy Duty Gratings

Heavy duty gratings are typically manufactured from robust materials such as steel, aluminum, or fiberglass. Their design varies according to their intended use, but they generally feature a grid-like structure that allows for efficient load distribution. The primary characteristics of heavy duty gratings include

1. Load Capacity Designed to bear high weights, these gratings can support substantial loads without compromising structural integrity. This makes them ideal for industrial environments where heavy machinery is in operation.

2. Durability Made from materials resistant to corrosion, wear, and impact, heavy duty gratings are built to last. For instance, steel gratings are often coated with protective finishes, while fiberglass gratings offer inherent resistance to rust and chemicals.

3. Slip Resistance Many heavy duty gratings are designed with textured surfaces or anti-slip features, ensuring safe footing even when exposed to wet or oily conditions. This is particularly crucial in environments where safety is a priority.

4. Customizability Heavy duty gratings can be customized in size, shape, and load capacity to meet specific project requirements. This flexibility allows for seamless integration into various applications.

Applications of Heavy Duty Gratings

Due to their strength and reliability, heavy duty gratings are used in a wide range of applications

1. Walkways and Platforms In industrial settings, heavy duty gratings are commonly used for walkways and work platforms, providing safe access to machinery and minimizing the risks of slips and falls.

heavy duty gratings

2. Drainage Systems Gratings are frequently utilized in drainage systems to cover pits or trenches, allowing for effective water flow while preventing debris from obstructing drainage paths.

3. Roadways and Loading Docks Heavy duty gratings can support the weight of vehicles and heavy loads, making them suitable for use in loading docks, access roads, and truck entry points.

4. Wastewater Treatment Facilities In environments exposed to harsh chemicals and constant wear, such as wastewater treatment plants, heavy duty fiberglass gratings are often the preferred choice, providing durability without rusting.

5. Marine Applications With their corrosion-resistant properties, heavy duty gratings are widely used in marine environments, such as docks and piers, where they withstand salty air and moisture.

Advantages of Heavy Duty Gratings

Investing in heavy duty gratings offers numerous advantages

1. Cost-Effectiveness While initial costs may be higher than lighter alternatives, the long lifespan and low maintenance requirements of heavy duty gratings often result in significant cost savings over time.

2. Enhanced Safety The slip-resistant features and robust design contribute to a safer environment for workers and pedestrians, reducing the likelihood of accidents.

3. Environmental Resistance Many heavy duty gratings are designed to withstand extreme weather conditions, chemical exposure, and heavy wear, making them suitable for outdoor use and in harsh environments.

4. Sustainability Many manufacturers offer gratings made from recycled materials, contributing to sustainable construction practices and reducing environmental impact.

In conclusion, heavy duty gratings are a key component of modern infrastructure, providing essential support in various industrial applications. Their robust design, coupled with the myriad of benefits they offer, makes them an invaluable choice for businesses focusing on safety, efficiency, and long-term cost-effectiveness. As industries continue to evolve, the demand for such durable and versatile solutions will undoubtedly grow, solidifying the role of heavy duty gratings in the future of construction and industrial design.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025