- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Exploring Different Types of Optical Gratings and Their Applications

Understanding Grating Types A Comprehensive Overview

Grating types are essential components in various optical applications, playing a pivotal role in the manipulation and analysis of light. These devices consist of a series of closely spaced lines or grooves, which diffract light into its constituent wavelengths. Gratings are commonly employed in spectrometers, telescopes, and lasers, among other optical instruments. They can be categorized based on several criteria, including their physical structure, the materials used, and the method of fabrication.

1. Types of Grating Based on Structure

Gratings can be broadly classified into three main types based on their physical structure transmission gratings, reflection gratings, and surface-relief gratings.

- Transmission Gratings These gratings transmit light through the grooves etched onto a transparent substrate. Transmission gratings are often made from glass or plastic and are employed in applications where light needs to pass through the grating. Due to their design, they are particularly effective for applications that require high resolution, making them a staple in spectroscopic devices.

- Reflection Gratings As the name suggests, these gratings reflect light rather than transmit it. They are made from materials such as aluminum or gold coated on a substrate. Reflection gratings are widely used in high-power applications, such as lasers, where maximizing light reflection is crucial. The efficiency of these gratings makes them suitable for applications requiring a strong diffracted signal.

- Surface Relief Gratings This type includes gratings that have a three-dimensional structure, with grooves carved into the surface of the material. Surface relief gratings can be utilized in both transmission and reflection modes and are characterized by their ability to provide a high degree of control over the light path due to the precise engineering of the groove shapes and depths.

grating types

2. Grating Types Based on Fabrication Method

The method used to fabricate gratings also influences their performance and applications. There are two primary techniques ruled gratings and holographic gratings.

- Ruled Gratings These gratings are created by mechanically scratching fine grooves into a surface. The precision of this method allows for the creation of high-quality gratings but can be time-consuming and limited in terms of complexity of groove patterns. Ruled gratings are known for their robustness and have been used extensively in traditional spectrometry.

- Holographic Gratings These are produced using laser interference techniques that create a pattern of constructive and destructive interference. Holographic gratings offer advantages in producing complex groove patterns and can achieve higher diffraction efficiency than ruled gratings. Their ability to be produced with high resolution makes them suitable for modern applications where precise control of light is required.

Conclusion

The variety of grating types available reflects the diverse needs of modern optical applications. Whether it is transmission, reflection, or surface-relief gratings, each type has its unique advantages that make it suitable for specific tasks. With advances in fabrication techniques such as ruled and holographic methods, the capabilities of gratings continue to grow, paving the way for innovations in fields ranging from telecommunications to medical diagnostics. As technology evolves, understanding these grating types remains crucial for anyone working in optical engineering and related disciplines.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

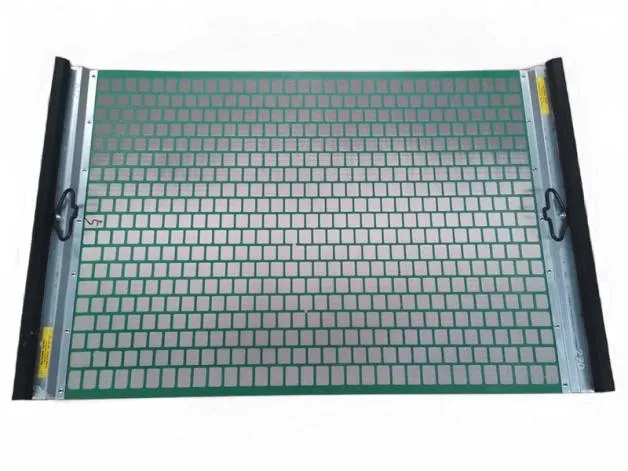

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025