- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Current Trends in Grating Steel Pricing and Market Analysis

Understanding Grating Steel Prices Factors and Trends

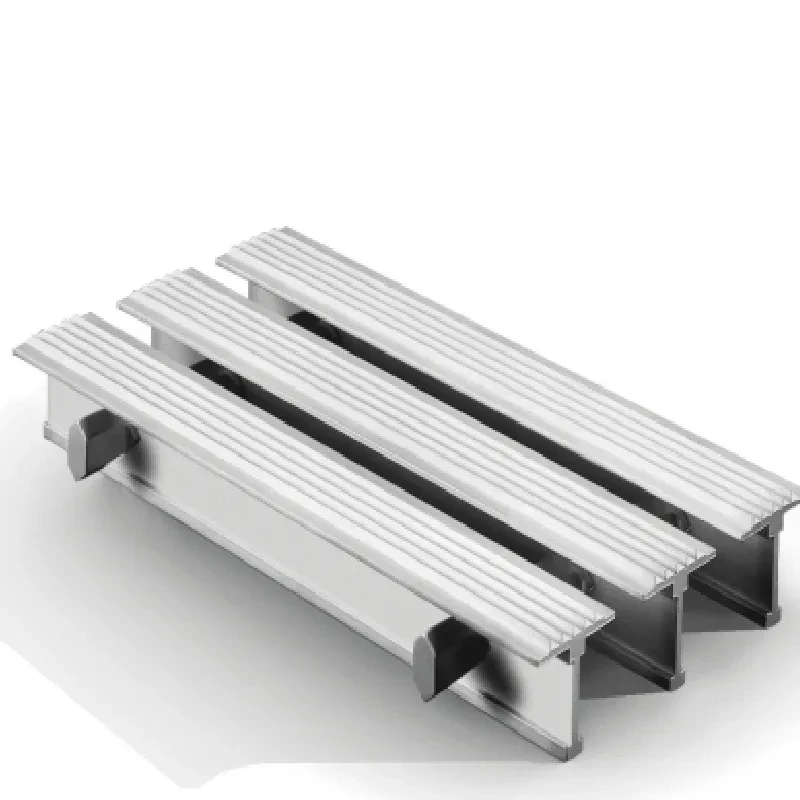

Grating steel, a critical material in industrial applications, plays a vital role in construction, manufacturing, and various engineering projects. This versatile product comes in different forms, primarily used for making walkways, platforms, and drainage covers. As demand for infrastructure development rises globally, understanding the factors influencing grating steel prices becomes essential for industry players.

One of the primary factors impacting grating steel prices is the cost of raw materials. Steel is derived from iron ore, and fluctuations in the prices of these raw materials directly affect finished product costs. Factors such as mining output, geopolitical events, and trade tariffs can lead to significant price variations. For instance, when iron ore prices increase due to supply chain disruptions or increased demand from countries like China, steel prices—thereby affecting grating steel—also tend to rise.

Another critical element influencing grating steel prices is production costs. The manufacturing process involves various stages, including casting, rolling, and finishing, all of which require energy and skilled labor. Any increase in energy prices—due to rising fuel costs or regulatory measures—can lead to higher production expenses. Furthermore, labor shortages or increased wage demands may contribute to escalating operational costs, pushing producers to increase their prices for grating steel.

Market demand is another significant factor that can drive the price of grating steel. As urbanization persists, there is an ever-growing need for safety and structural solutions in construction. Industries such as oil and gas, aerospace, and automotive often require specialized steel grating products, which further fuels demand. Moreover, seasonal variations can impact construction activities, leading to fluctuating prices. For example, during peak construction seasons, the demand for grating steel tends to surge, potentially resulting in higher prices.

grating steel price

Trade policies and global economics are also pivotal in shaping grating steel prices. Tariffs, trade agreements, and the imposition of import/export restrictions can cause sudden price shifts. The ongoing trade tensions between major economies can create uncertainty in the steel market, influencing prices worldwide. Additionally, currency fluctuations can affect pricing, especially for countries that rely on imported steel products.

Emerging technologies and sustainable practices are playing an increasingly crucial role in the steel industry. The push for greener manufacturing processes is affecting the costs associated with producing steel. Companies investing in environmentally friendly technologies often incur higher initial costs, which may be passed on to consumers. However, the long-term benefits often include energy savings and improved efficiencies, which can stabilize prices over time.

In recent years, the trend of recycling steel has gained momentum, leading to a more sustainable approach in the industry. This practice can help soften price fluctuations, as recycled materials often come at a lower cost than virgin ore. As more manufacturers take advantage of recycled steel, the overall price stability of grating steel may improve, benefiting a wide range of industries.

In conclusion, grating steel prices are influenced by a complex interplay of raw material costs, production expenses, market demand, global economic factors, and technological advancements. For stakeholders in the construction and manufacturing sectors, keeping a close eye on these variables is crucial for making informed purchasing decisions. As the demand for grating steel continues to grow, understanding these trends will help mitigate risks associated with price volatility, paving the way for more strategic investment and project planning.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025