- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Understanding Grating Prices for Better Budgeting and Cost Management

Understanding Grating Prices Factors and Implications

Grating prices, often overlooked, play a critical role in various industries, from construction to manufacturing. These prices can fluctuate due to a myriad of factors, influencing supply chains, project budgets, and ultimately, consumer costs. Understanding the dynamics behind grating prices is essential for stakeholders across different sectors.

First and foremost, the material composition of the grating significantly impacts its price. Common materials include steel, aluminum, fiberglass, and plastic. Steel grating, known for its strength and durability, often commands a higher price point due to the cost of raw materials and the manufacturing processes involved. On the other hand, while aluminum grating is lighter and resistant to corrosion, its price may vary based on market demand and the availability of aluminum. Recent trends show that the demand for high-quality, lightweight materials is increasing, which can push prices upward, particularly in industries where weight is a crucial factor, like aerospace and automotive.

Another significant factor influencing grating prices is the manufacturing process. Custom or specialty gratings often come at a premium due to the additional design and fabrication efforts involved. Industries seeking unique specifications for safety, aesthetics, or performance will find that customized grating options can lead to higher costs. Additionally, the complexity of production methods, such as welding or molding, can also affect pricing. Gratings that require advanced manufacturing techniques are generally more expensive to produce, consequently increasing their market price.

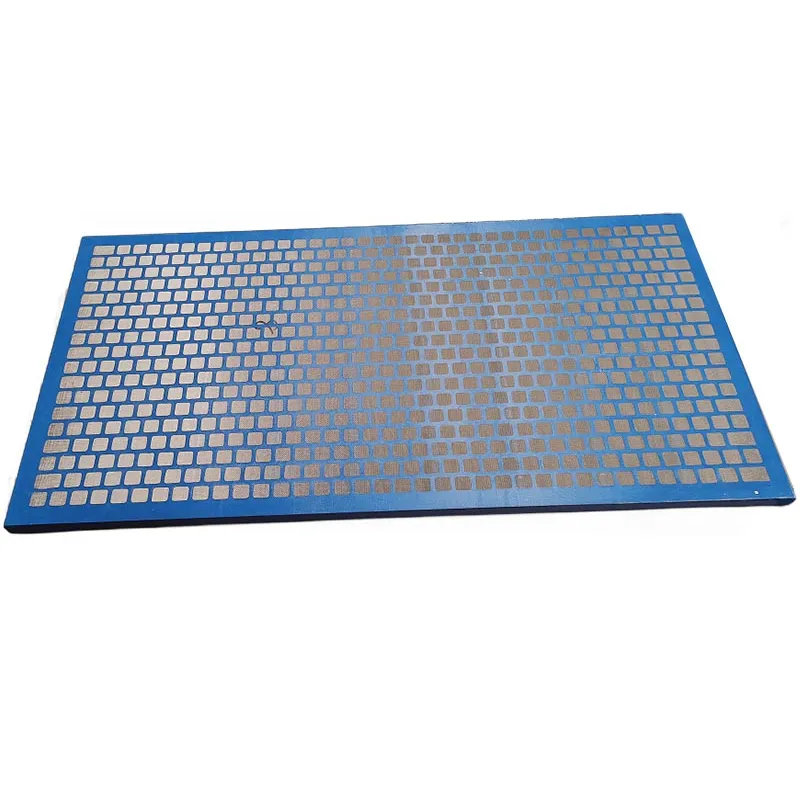

grating price

Market dynamics, including supply and demand, further contribute to variations in grating prices. Supply chain disruptions, such as those experienced during global events (e.g., the COVID-19 pandemic), can lead to material shortages. When supply dwindles and demand remains steady or increases, prices inevitably rise. Conversely, if a surplus of materials occurs, prices may drop. Economic conditions, such as inflation, can also play a pivotal role in the overall pricing structure of gratings. Manufacturers often adjust their prices in response to rising costs associated with labor, energy, and raw materials.

Import tariffs and trade regulations are additional elements that can impact grating prices. Countries imposing tariffs on imported materials can lead to increased costs for manufacturers who rely on foreign supplies, which can trickle down to the end consumer. Staying updated on international trade policies is crucial for businesses that procure materials across borders, affecting their pricing strategies.

Lastly, seasonal factors and industry-specific trends can cause fluctuations in grating prices. For instance, construction activities may peak during certain seasons, driving up the demand for construction-grade gratings and subsequently their cost. Understanding these seasonal trends can help businesses plan their procurement strategies effectively.

In conclusion, grating prices are influenced by a variety of factors, including material composition, manufacturing processes, supply and demand dynamics, market conditions, and external regulations. By comprehensively analyzing these elements, stakeholders can better anticipate price changes and make informed decisions that align with their economic objectives. Whether you're in construction, manufacturing, or a related field, being aware of how these factors intertwine can lead to more effective budgeting and resource management.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025