- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

grating price

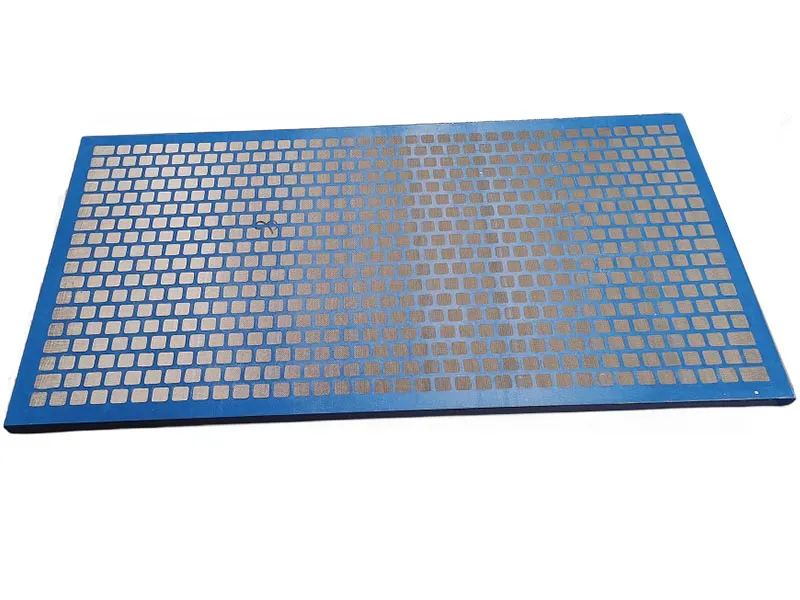

Understanding Grating Prices Factors Affecting Market Trends

Grating, in its various forms, plays a crucial role in numerous industries, from construction to manufacturing, and even in agricultural settings. The price of grating materials fluctuates due to a variety of factors, making it essential for buyers and sellers to stay informed about current market trends and pricing strategies.

One of the primary factors influencing grating prices is the type of material used

. Gratings are commonly made from steel, aluminum, fiberglass, and other composite materials. Steel grating, for example, is often favored for its strength and durability, but fluctuations in steel prices due to global market conditions can significantly impact grating costs. Similarly, aluminum might be more expensive but offers advantages in terms of weight and corrosion resistance; hence, the choice of material directly affects overall pricing.Market demand also plays a pivotal role in grating pricing. In booming sectors, such as construction or renewable energy, the need for grating components increases, leading to heightened demand. When demand surpasses supply, prices inevitably rise. Conversely, during economic downturns or reduced industrial activity, demand may diminish, resulting in lower prices.

Supply chain dynamics are another crucial element. Logistics, transportation costs, and availability of raw materials can significantly influence grating prices. If a particular region faces transportation issues or supply chain disruptions, the cost to source gratings may increase, thus pushing prices up. This was notably observed during the COVID-19 pandemic, where many industries experienced delays and shortages that affected pricing.

grating price

Another aspect to consider is the manufacturing process. Innovations in production technologies can lead to cost reductions, allowing manufacturers to offer more competitive pricing. For instance, advancements in automated production processes can streamline operations, minimizing labor costs, and subsequently reducing the price of the final product. However, if manufacturers opt for more environmentally friendly methods or materials, these costs might be passed on to consumers, affecting pricing structures.

Additionally, the geographical location plays a significant role in grating prices. Regions with higher operational costs or stringent regulatory requirements may see elevated prices compared to areas with lower overhead. Moreover, local competition can either drive prices up or down depending on the number of available suppliers and the nature of their offerings.

It's also critical to consider seasonal variations. Certain industries experience seasonal peaks, directly correlating with increased grating usage. For example, construction projects often ramp up during warmer months, leading to greater demand for grating materials, which can cause prices to spike. Buyers often need to plan ahead and consider these seasonal trends when purchasing materials.

Lastly, understanding the role of market fluctuations in global economics is essential. Events such as geopolitical tensions, trade tariffs, or changes in trade regulations can create uncertainty in the pricing of raw materials. This uncertainty can ripple through to finished products, including grating.

In summary, the price of grating is influenced by a combination of material costs, demand cycles, supply chain logistics, manufacturing processes, geographical aspects, and broader economic conditions. For stakeholders in the industry, staying abreast of these factors is crucial for making informed purchasing and pricing decisions. Ultimately, a thorough understanding of grating pricing can lead to better strategic planning and increased efficiency in various applications across multiple sectors.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025