- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

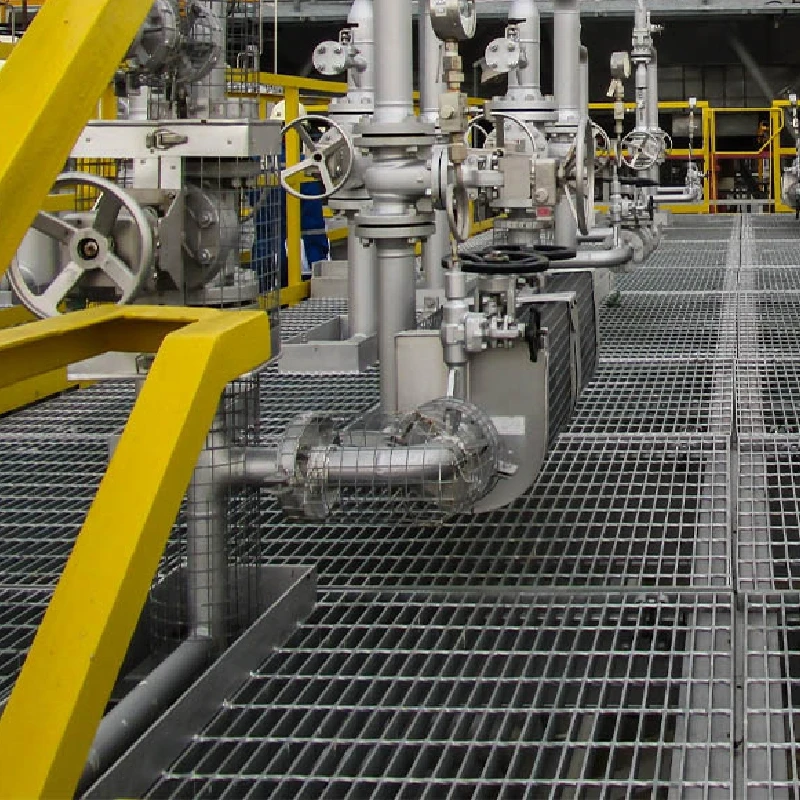

grating hot dip galvanized

Understanding Grating Hot Dip Galvanized A Comprehensive Overview

When it comes to industrial applications, the choice of materials is crucial for ensuring durability and effectiveness in various environments. One such material that has gained immense popularity is hot dip galvanized grating. This process, combined with the unique properties of grating, makes it a preferred choice for various construction and maintenance projects. In this article, we’ll delve into what grating hot dip galvanized is, its benefits, applications, and considerations for use.

What is Hot Dip Galvanizing?

Hot dip galvanizing is a process where steel or iron is coated with a layer of zinc to protect it from corrosion. In this method, the metal is immersed in molten zinc at temperatures around 450°C (842°F), creating a metallurgically bonded protective layer. The zinc acts as a barrier against moisture and corrosive substances, ensuring that the underlying metal remains intact and free from rust. This process is widely used in various industries, including construction, automotive, and agriculture.

What is Grating?

Grating refers to a framework of material that consists of a series of parallel bars, often constructed from steel, aluminum, or fiberglass, with spaces in between. These structures provide a sturdy surface that allows for water drainage, air circulation, and light passage. Grating is commonly used in walkways, platforms, and other surfaces requiring strength and safety while minimizing the accumulation of debris or liquids.

Benefits of Grating Hot Dip Galvanized

1. Corrosion Resistance The primary benefit of hot dip galvanizing is its superior resistance to corrosion. This feature is especially important in environments exposed to industrial chemicals, saltwater, or extreme weather conditions.

2. Durability Galvanized grating can last significantly longer than uncoated grating, often exceeding 50 years with minimal maintenance. This longevity translates to lower replacement costs over time.

3. Safety Grated surfaces enhance safety by providing a slip-resistant area. The open design allows for drainage, reducing the risk of water pooling that can lead to accidents.

4. Cost-Effectiveness While the initial investment in hot dip galvanized grating may be higher than that of untreated materials, the long-term savings generated from reduced maintenance and replacement needs make it a wise economic choice.

Applications of Grating Hot Dip Galvanized

grating hot dip galvanized

Given its unique advantages, hot dip galvanized grating is utilized in numerous applications across various industries

- Industrial Facilities Factories and warehouses use grating for walkways, loading docks, and stairways to ensure worker safety and operational efficiency.

- Wastewater Treatment Plants The corrosion-resistant properties of galvanized grating make it ideal for environments where exposure to chemicals and moisture is prevalent.

- Power Plants Grating is used in areas where equipment needs to be accessible yet safe, facilitating maintenance while ensuring personnel safety.

- Construction Sites Temporary walkways and platforms made from galvanized grating are often employed on construction sites to manage foot traffic and equipment movement.

Considerations for Use

While the benefits of hot dip galvanized grating are numerous, several factors should be considered

1. Weight Galvanized grating can be heavier than other materials, which may affect installation requirements. It's essential to ensure that the supporting structures can accommodate the weight.

2. Thermal Expansion Like all metals, galvanized grating can expand and contract with temperature changes. Proper allowances should be made in design to avoid structural issues.

3. Aesthetic Considerations The steel surface may not be visually appealing for all applications, and some projects might require additional coatings or treatments to achieve a desired look.

4. Welding and Fabrication While fabrication can be done post-galvanizing, any welding must be followed up with additional galvanizing to maintain corrosion resistance.

Conclusion

Grating hot dip galvanized stands out as a material of choice in environments where durability, safety, and corrosion resistance are paramount. With its diverse applications and long lifespan, it offers an effective solution for numerous industries. By understanding the benefits, applications, and considerations associated with this material, businesses can make informed decisions that enhance their operational efficiency and safety. Whether for new constructions or renovations, hot dip galvanized grating is indeed a valuable asset worth considering.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025