- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

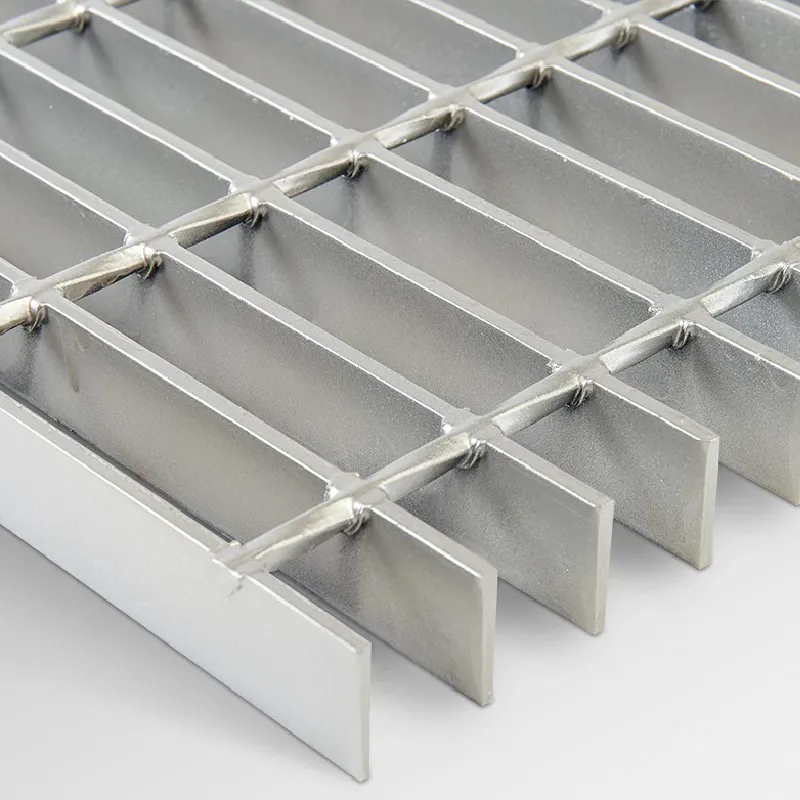

Enhanced Durability of Hot Dip Galvanized Grating for Long-lasting Structural Solutions

The Importance of Grating in Hot-Dip Galvanized Applications

When it comes to construction and industrial applications, the choice of materials can significantly impact the longevity, safety, and functionality of a project. Among these materials, grating—particularly hot-dip galvanized grating—emerges as a superior choice for various environments. This article explores the advantages of hot-dip galvanized grating and its applications in diverse fields.

What is Hot-Dip Galvanization?

Hot-dip galvanization is a process that involves the coating of steel or iron with a layer of zinc to enhance its corrosion resistance. This process entails submerging the metal in molten zinc, allowing it to form a robust bond. The result is a durable, long-lasting finish that protects the underlying metal from environmental elements, making hot-dip galvanized products ideal for outdoor and submerged applications.

Benefits of Hot-Dip Galvanized Grating

1. Corrosion Resistance The primary benefit of hot-dip galvanized grating is its exceptional resistance to corrosion. Many industries, including wastewater treatment, marine applications, and chemical processing, face harsh conditions that can rapidly deteriorate unprotected metals. The zinc coating acts as a barrier, preventing moisture and corrosive agents from reaching the steel beneath, thus extending the life of the grating significantly.

2. Durability and Strength Steel grating is known for its strength and load-bearing capabilities. With the added protection of hot-dip galvanization, this durability is further enhanced. The grating can withstand heavy traffic loads and abrasive conditions, making it suitable for industrial flooring, walkways, and platforms.

grating hot dip galvanized

3. Low Maintenance Another appealing aspect of hot-dip galvanized grating is the low maintenance required to keep it in good condition. While other coatings may require regular touch-ups and maintenance, galvanization offers a long-lasting solution that can endure decades with minimal oversight, resulting in cost savings over time.

4. Safety Features Safety is a critical concern in many applications. Grating often features slip-resistant surfaces that improve traction, reducing the risk of accidents in wet or oily environments. The openness of the grating also allows for quick drainage of fluids, further enhancing safety by minimizing hazards from pooling water.

5. Versatile Applications Hot-dip galvanized grating finds a diverse range of applications. It is commonly used in industrial platforms, catwalks, stair treads, and safety barriers. Moreover, its lightweight yet robust nature allows for easy installation and versatility in design, fitting various architectural and functional requirements.

6. Sustainability The use of metals like steel and zinc aligns with sustainable practices. Steel is recyclable, and the longevity of hot-dip galvanized products means that there is less need for replacements, which ultimately reduces waste.

Conclusion

Hot-dip galvanized grating stands out as a material with multifaceted benefits, making it a preferred choice across numerous industries. Its resistance to corrosion, durability, low maintenance needs, safety features, and adaptability render it essential for construction, manufacturing, and infrastructure projects. As industries continue to seek efficient, reliable, and long-lasting solutions, the demand for hot-dip galvanized grating is likely to grow. In a world where durability and safety are paramount, embracing materials like hot-dip galvanized grating is a forward-thinking choice that aligns with both operational efficiency and environmental sustainability.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025