- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Grating Solutions with Hot Dip Galvanized Finish for Enhanced Durability and Protection

Understanding Grating Hot Dip Galvanized A Comprehensive Overview

When it comes to industrial applications, safety, durability, and cost-effectiveness are paramount. One of the prominent solutions that fulfill these requirements is grating hot dip galvanized. This process fuses two essential concepts—grating and hot dip galvanization—offering numerous benefits across various sectors, including construction, manufacturing, and infrastructure.

What is Grating?

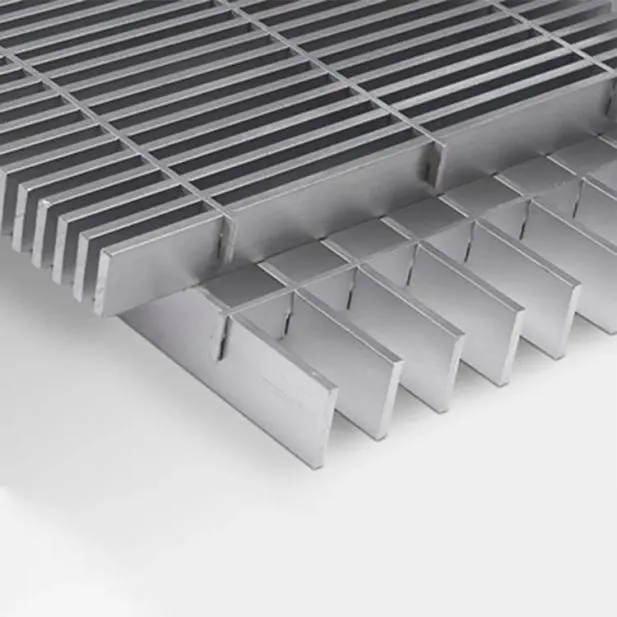

Grating refers to a structure made from a series of parallel and perpendicular bars, which creates a grid-like framework. This design offers remarkable strength while allowing light, air, and liquids to pass through. Grating is widely used for flooring, walkways, platforms, and even parking garages due to its ability to bear heavy loads. Common materials used for grating include steel, fiberglass, and aluminum, with steel being the most popular due to its strength and affordability.

The Hot Dip Galvanization Process

Hot dip galvanization is a metallurgical process that involves coating steel with a layer of zinc. This is achieved by immersing prepared steel components in molten zinc, which creates a metallurgical bond between the zinc and the steel. The primary purpose of galvanization is to protect the underlying steel from corrosion and rust, thereby extending its lifespan significantly. The hot dip galvanization process is particularly favored due to its thoroughness; it coats even the most intricate geometries and hard-to-reach areas.

Benefits of Grating Hot Dip Galvanized

1. Corrosion Resistance The most significant advantage of hot dip galvanized grating is its exceptional resistance to corrosion. The zinc coating acts as a barrier against moisture and corrosive substances, protecting the steel beneath it. This quality is particularly invaluable in environments exposed to harsh weather conditions, chemicals, and marine settings.

grating hot dip galvanized

2. Longevity Grating that has gone through hot dip galvanization can last for decades with minimal maintenance. While untreated steel can start to rust within a year or two when exposed to outdoor elements, a hot dip galvanized structure can last 30 years or more, depending on environmental conditions.

3. Cost-Effectiveness Although the initial investment for hot dip galvanized grating might be higher than untreated options, the long-term savings on maintenance and replacement costs make it an economically viable solution. Additionally, its durability can reduce downtime in industrial applications, enhancing productivity.

4. Versatility Grating hot dip galvanized can be used in various settings, from walkways and platforms to stair treads and drainage covers. Its adaptability makes it suitable for numerous applications across different industries, including oil and gas, construction, and waste management.

5. Aesthetics Unlike untreated steel, which can rust and become unsightly over time, hot dip galvanized grating maintains its appearance. The uniform zinc coating gives it a clean and modern look, making it more visually appealing for commercial applications.

6. Safety The open design of grating provides excellent slip resistance and drainage capabilities. When combined with hot dip galvanization, these features contribute to a safer working environment, reducing the risk of accidents.

Conclusion

Grating hot dip galvanized stands as a testament to modern engineering and materials science, offering an optimal solution that combines safety, durability, and cost-effectiveness. With its outstanding resistance to corrosion, longevity, and minimal maintenance needs, this innovation has become a standard in various industries. Whether for industrial flooring, public walkways, or architectural applications, hot dip galvanized grating proves to be a reliable choice that not only meets but exceeds expectations. As industries continue to seek sustainable and efficient alternatives, the significance of grating hot dip galvanized is likely to grow, paving the way for further advancements and applications in the future.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025