- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

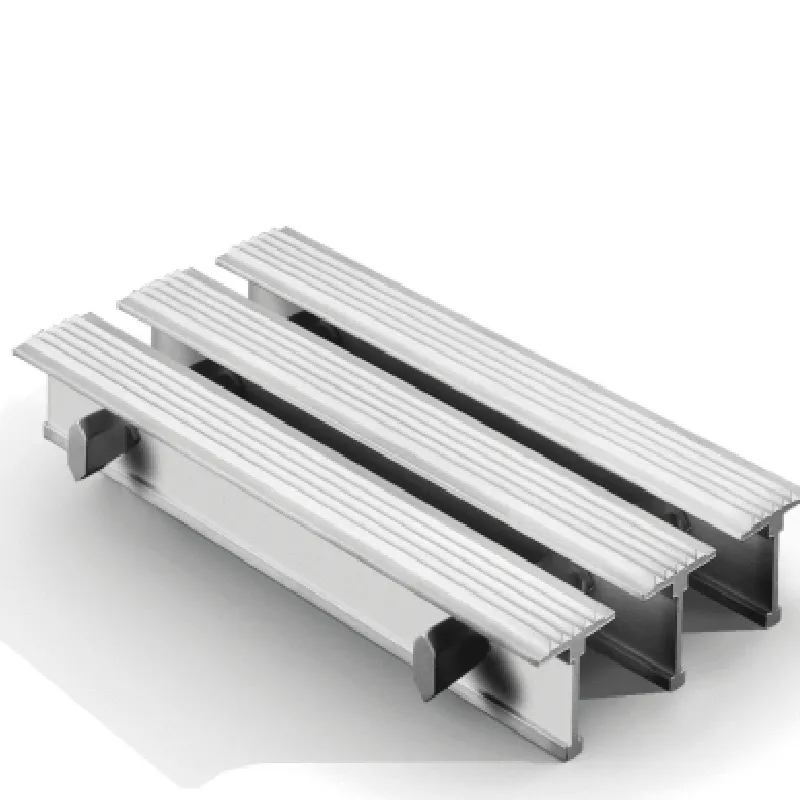

grating hot dip galvanized

Understanding Grating Hot Dip Galvanized Steel The Perfect Solution for Durability and Corrosion Resistance

In the realm of construction and industrial applications, materials must withstand harsh environments while maintaining structural integrity and visual appeal. One solution that has gained significant recognition is hot dip galvanized grating. This process not only enhances the functionality of metal grating but also extends its lifespan, making it an indispensable choice in various sectors.

What is Hot Dip Galvanization?

Hot dip galvanization is a metallurgical process where steel is coated with a layer of zinc to protect it from corrosion. During this process, the steel is immersed in molten zinc, creating a robust bond that ensures longevity. This method provides a thick, durable coating that can withstand environmental factors such as moisture, chemicals, and extreme temperatures.

The Importance of Grating in Construction

Grating, typically made from metals like steel, is used to create walkways, platforms, and drainage systems in buildings and industrial sites. While the primary function of grating is to provide a safe and stable footing, its design must also consider challenges posed by the surrounding environment. Consequently, the combination of grating and hot dip galvanization leads to a protective element that caters to both safety and longevity.

Advantages of Hot Dip Galvanized Grating

1. Corrosion Resistance The most significant advantage of hot dip galvanized grating is its ability to resist corrosion. The zinc coating acts as a barrier to moisture and other corrosive elements, making it ideal for outdoor use or in industrial settings where exposure to harsh conditions is common.

2. Extended Lifespan Due to the inherent properties of zinc, hot dip galvanized grating can last up to several decades without requiring replacement or extensive maintenance. This reduced need for repairs translates to lower lifecycle costs for businesses and projects.

3. Aesthetic Appeal While functionality is crucial, aesthetics also play a role in material selection. Hot dip galvanized grating has a unique silver-gray finish that can enhance the appearance of a structure, providing a neat and modern look.

grating hot dip galvanized

4. Safety Features Many types of grating designs incorporate slip-resistant surfaces. When combined with the hot dip galvanization process, the result is a safe walking surface that reduces the likelihood of accidents, contributing to overall workplace safety.

5. Ease of Installation Hot dip galvanized grating is typically lightweight yet strong, allowing for easy handling and installation. This feature is particularly beneficial on construction sites where time and efficiency are critical.

Applications of Hot Dip Galvanized Grating

The applications of hot dip galvanized grating are vast and diverse, spanning various industries such as

- Industrial Systems Used extensively in factories and manufacturing facilities for walkways, platforms, and stairways, providing safe access to machinery and equipment. - Commercial Buildings In shopping malls and public spaces, grating solutions enable proper drainage while allowing for pedestrian traffic.

- Transportation Infrastructure Hot dip galvanized grating finds its place in bridge decks and highway applications, where durability is paramount.

- Marine Environments Given its resistance to saltwater corrosion, this type of grating is commonly used in ports and harbors.

Conclusion

In a world where resilience and safety are paramount, hot dip galvanized grating emerges as a champion in industrial construction. Its unique combination of strength, durability, and aesthetic appeal makes it an ideal choice for various applications. The process of hot dip galvanization not only enhances the material's longevity but also adds value to the structures it supports. As industries continue to seek out reliable materials that meet safety standards and financial considerations, hot dip galvanized grating stands out as a practical and effective solution. Embracing this technology can lead to improved project outcomes, making it a worthy investment for any construction endeavor.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025