- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

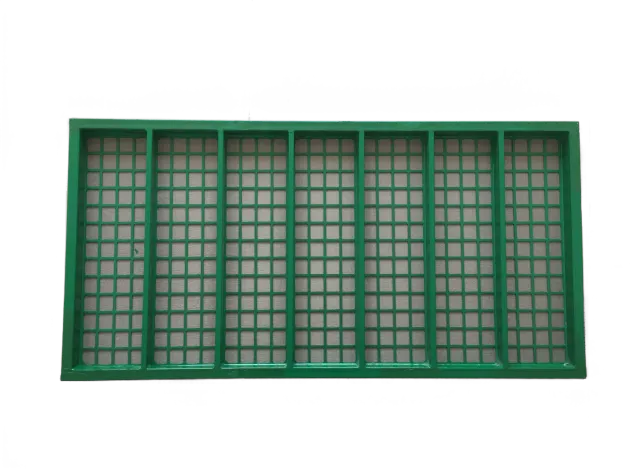

grating hot dip galvanized

Understanding Grating Hot Dip Galvanized Steel Benefits and Applications

Hot dip galvanizing is a process that involves coating steel with a layer of zinc to provide enhanced corrosion resistance. This technique is particularly important in the construction and manufacturing industries, where durability and strength are paramount. Among the myriad applications of hot dip galvanized materials, grating has emerged as an essential component, offering both functional and aesthetic advantages.

What is Grating?

Grating refers to a framework of parallel or crossed bars, often used for flooring, walkways, and various other applications where strength and air circulation are required. Grates are commonly seen in industrial environments, commercial buildings, and outdoor settings. The primary purpose of grating is to support loads while allowing for drainage or visibility beneath it.

The Process of Hot Dip Galvanizing

The hot dip galvanizing process begins with cleaning the steel to remove any rust, dirt, or grease. This is typically achieved through a combination of mechanical abrasion and chemical cleaning methods. Once the surface is clean, the steel is submerged in a bath of molten zinc, generally at temperatures around 450 degrees Celsius (about 840 degrees Fahrenheit). The zinc reacts with the iron in the steel, forming a tightly adhered coating that provides impressive protection against corrosion. After the galvanizing process, the grating is usually cooled and inspected for quality assurance.

Benefits of Hot Dip Galvanized Grating

1. Corrosion Resistance The primary advantage of hot dip galvanization is the creation of a robust barrier against corrosion. Hot dip galvanized grating can withstand harsh environments, including exposure to moisture, chemicals, and varying temperatures, making it suitable for applications in marine and industrial settings.

2. Longevity Hot dip galvanized products often have a lifespan of several decades. This longevity means reduced maintenance costs and fewer replacements over time, leading to significant cost savings for businesses and contractors.

3. Strength and Stability Grating is designed to handle heavy loads, and when combined with hot dip galvanization, it retains its structural integrity even in challenging conditions. This combination is crucial in industries such as construction, wastewater management, and chemical processing.

4. Aesthetic Appeal While durability is the priority, hot dip galvanized grating also offers a clean, uniform appearance. The silver-gray finish of galvanized steel is visually appealing, making it suitable for both functional and decorative purposes in architectural applications.

grating hot dip galvanized

5. Ease of Installation Hot dip galvanized grating is generally lightweight and easy to handle. Its standardization in sizes and dimensions enables quick installation, minimizing labor costs and project timelines.

Applications of Hot Dip Galvanized Grating

The applications for hot dip galvanized grating are vast and varied. Some of the most common uses include

- Walkways and Platforms In factories and warehouses, grating provides safe pathways that allow for both pedestrian and vehicle traffic while facilitating drainage and ventilation.

- Staircases Grating is often used in stair treads to offer slip resistance and prevent debris accumulation.

- Drain Covers Hot dip galvanized grating serves effectively as drain covers in outdoor settings, ensuring that water drains while preventing large debris from entering drainage systems.

- Rooftop Gardens and Patios The aesthetic quality of galvanized grating makes it suitable for use in garden designs and rooftop patios, where it can enhance the visual appeal while being functional.

- Industrial Equipment Platforms Many manufacturing facilities utilize galvanized steel grating for platforms, ensuring safe access to machinery and equipment.

Conclusion

In summary, hot dip galvanized grating emerges as a critical component in various industries due to its exceptional corrosion resistance, durability, and aesthetic appeal. By investing in hot dip galvanized materials, businesses can ensure the longevity and safety of their structures, ultimately leading to reduced costs and enhanced operational efficiency. As construction and manufacturing demands continue to grow, the role of galvanized grating will undoubtedly expand, reinforcing its status as a cornerstone material in modern engineering.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025