- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

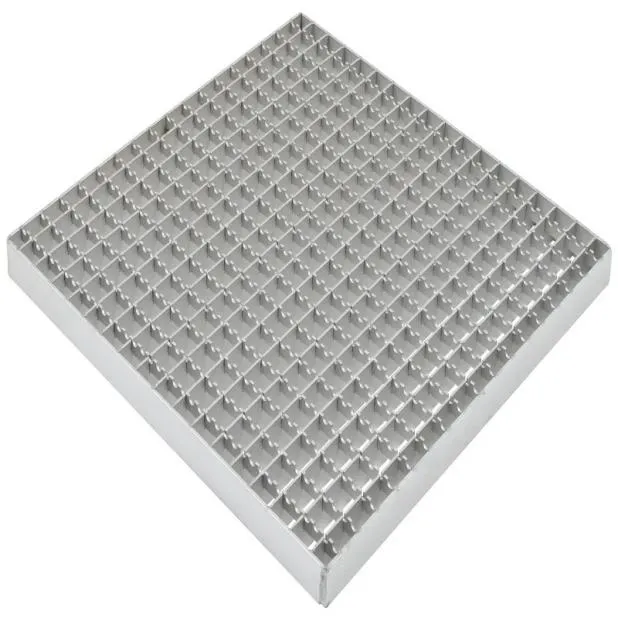

grating hot dip galvanized

Understanding Grating The Benefits of Hot Dip Galvanization

Grating is an essential component in various industrial applications, providing safety, support, and accessibility. Its uses range from walkways and platforms to drainage covers and equipment access. One of the most effective treatments for enhancing the longevity and durability of metal gratings is hot dip galvanization. This article explores the process of hot dip galvanization, its benefits, and why it is the preferred choice in many sectors.

What is Hot Dip Galvanization?

Hot dip galvanization is a process of coating iron or steel with a layer of zinc to protect it from corrosion. The method involves submerging the metal grating into a bath of molten zinc at temperatures around 450 degrees Celsius (about 842 degrees Fahrenheit). This ensures that the zinc bonds metallurgically to the iron, forming a robust and durable coating.

The hot dip galvanization process involves several steps. First, the metal grating is cleaned to remove any rust, grease, or other contaminants. This step, known as pickling, ensures that the surface is adequately prepared for zinc application. After pickling, the grating is rinsed and submerged in a flux solution, typically made of zinc ammonium chloride, which prevents oxidation of the metal before zinc coating. Finally, the grating is dipped into the molten zinc bath, where it undergoes a metallurgical reaction to form a durable zinc-based layer.

Benefits of Hot Dip Galvanized Grating

1. Corrosion Resistance The primary advantage of hot dip galvanization is its unmatched resistance to corrosion. Zinc acts as a sacrificial anode, meaning it will corrode before the underlying steel. This property extends the lifespan of the grating significantly, making it ideal for outdoor and harsh environments.

2. Increased Durability The galvanization process results in a thick, robust coating that is often tougher than other surface treatments. This durability protects the grating from physical damage, wear and tear, and impact, ensuring reliable performance over time.

3. Cost-Effectiveness Although the initial investment in hot dip galvanization may be higher compared to other treatments, the long-term savings are substantial. The extended life expectancy of galvanized grating reduces the need for frequent replacements and maintenance, translating to lower overall costs.

grating hot dip galvanized

4. Versatility Hot dip galvanized grating can be used in various applications, including industrial facilities, chemical plants, wastewater treatment plants, and more. Its ability to withstand harsh conditions without compromising structural integrity makes it a versatile choice across different industries.

5. Aesthetic Appeal Many industries prioritize aesthetics alongside functionality. Hot dip galvanization provides a clean and appealing finish, enhancing the overall appearance of grating used in public spaces and structures, such as walkways or rooftop terraces.

Environmental Benefits

In addition to its advantages in durability and cost, hot dip galvanization is also an environmentally friendly option. Zinc is a naturally abundant material, and the recycling process for galvanized steel is straightforward. Galvanized steel can be recycled indefinitely without losing its properties, contributing to a reduction in waste and supporting sustainability efforts.

Industry Applications

Hot dip galvanized grating finds applications in a wide range of industries. In construction and architecture, it’s often used for flooring, stair treads, and balconies due to its slip-resistant surface. In the manufacturing sector, it supports machinery and elevates maintenance access in safe, stable manners.

Moreover, hot dip galvanized gratings are extensively used in transportation infrastructure, including parking structures, bridges, and ramps, where durability and safety are paramount. They are also employed in various utilities, such as power plants and telecommunication towers, where corrosion resistance and strength are critical.

Conclusion

In summary, hot dip galvanization is an indispensable process that enhances the performance and longevity of metal grating in various applications. Its superior corrosion resistance, combined with durability and economic benefits, makes it a preferred choice across many industries. As the demand for reliable and sustainable materials continues to grow, hot dip galvanized grating stands out as a practical solution, ensuring safety and efficiency in an increasingly demanding industrial landscape.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025