- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

grating galvanized

Understanding Grating Galvanized Steel An In-Depth Overview

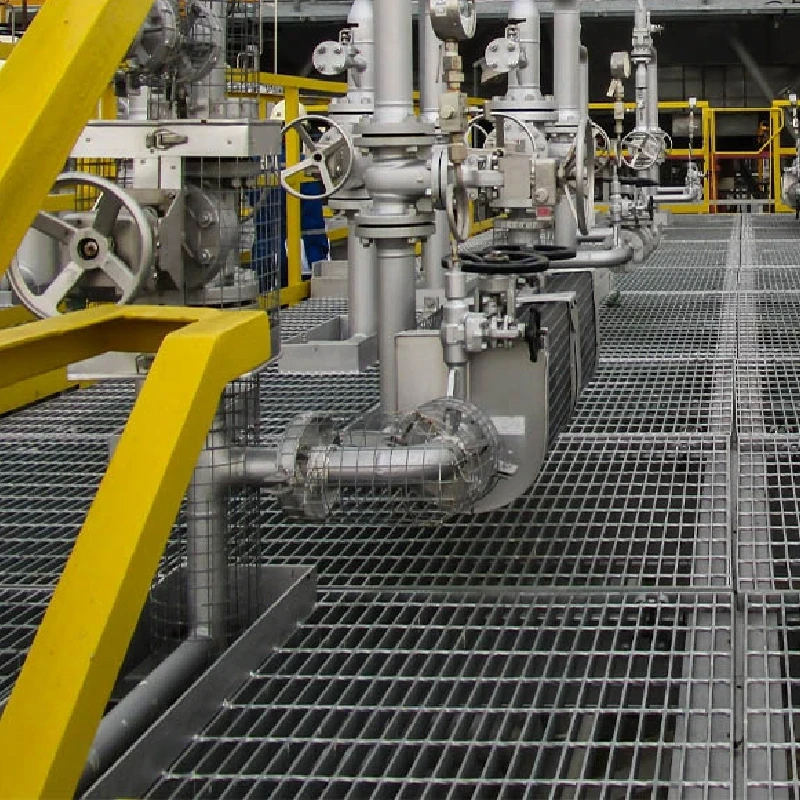

Grating galvanized steel is a crucial material in various industrial and architectural applications around the globe. Often used in walkways, platforms, and drainage covers, galvanized steel grating combines strength, durability, and versatility. This article will explore the process of galvanization, the benefits of using galvanized steel grating, its applications, and the factors to consider when selecting this type of grating.

Galvanization is a process that involves coating steel or iron with a layer of zinc to protect it from corrosion. This protective coating is typically achieved through hot-dip galvanization, where the steel grating is immersed in molten zinc. The result is a durable barrier that prevents corrosion from moisture, chemicals, and environmental factors. The galvanizing process ensures that even the smallest crevices of the steel are coated, offering long-lasting protection against rust and degradation.

Understanding Grating Galvanized Steel An In-Depth Overview

The versatility of galvanized steel grating cannot be overstated. It is available in a variety of shapes, sizes, and configurations to meet the specific needs of different applications. Common types of grating include welded grating, riveted grating, and press-locked grating. Each of these types serves distinct purposes, whether it be for providing structural support, allowing light and air circulation, or facilitating drainage.

grating galvanized

Galvanized steel grating finds its applications in numerous fields. In construction, it is used for flooring, stair treads, and safety barriers. In the waste management sector, it is often utilized in drainage systems to allow for effective water flow while preventing debris from clogging. It is also widely used in various industries, including petrochemical, food processing, and pharmaceuticals, due to its resistance to diverse chemical environments.

When selecting galvanized steel grating for a project, several factors must be considered. First and foremost is the selection of the appropriate grating type based on load requirements and environmental conditions. Understanding the specific needs of the application, including the type and weight of foot traffic or machinery that will be present, is essential to ensure safety and longevity. Additionally, the spacing and dimensions of the grating bars should be evaluated to meet relevant safety standards.

Cost is another critical consideration. While galvanized steel grating may have a higher initial cost compared to non-galvanized options, its longevity and reduced maintenance requirements make it a cost-effective choice in the long run. Investing in quality galvanized grating can lead to savings on repairs and replacements over time.

In summary, grating galvanized steel is a vital material that offers a combination of durability, versatility, and long-term cost-effectiveness. Its robust nature makes it suitable for a wide range of applications, from industrial settings to residential projects, ensuring safety and functionality. By understanding the galvanization process and the key factors in selecting the right grating, businesses and builders can make informed decisions that enhance the performance and reliability of their structures.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025