- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Benefits and Applications of Grating Galvanized Steel in Modern Construction Projects

Understanding Grating and Galvanized Steel A Comprehensive Overview

In the world of construction and manufacturing, the choice of materials plays a crucial role in ensuring both functionality and longevity. Two terms that frequently arise in discussions about durable building materials are grating and galvanized steel. Although often used in various applications, their combination can lead to superior outcomes in many projects. This article delves into the principles and benefits of grating made from galvanized steel, exploring its applications, advantages, and considerations.

What is Grating?

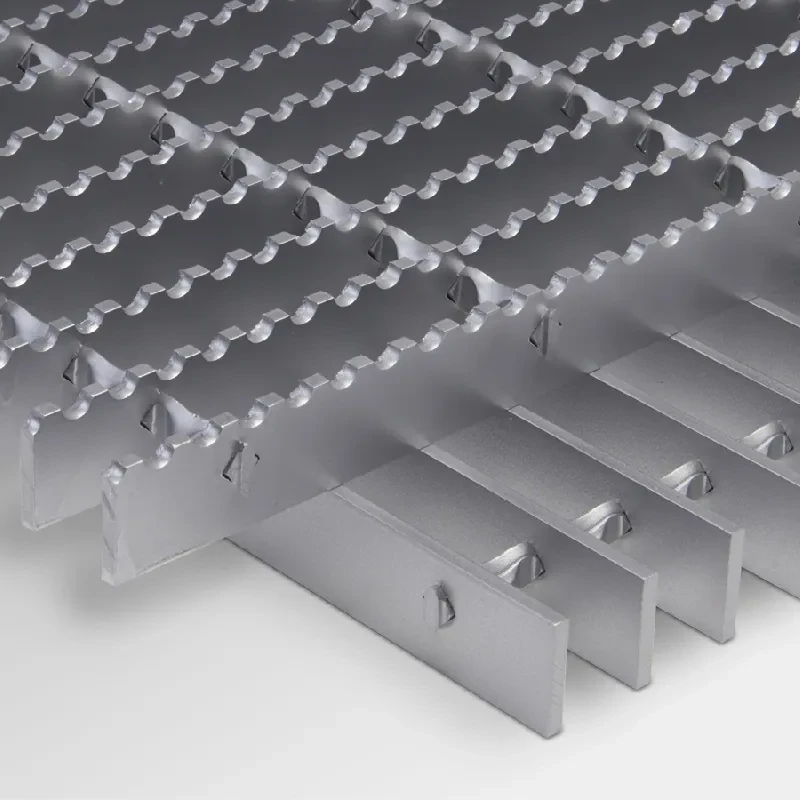

Grating is a structured assembly of interconnected bars or slats that create an open surface, allowing light, air, and water to pass through while providing support and stability. It can be fabricated from a variety of materials, including steel, aluminum, fiberglass, and plastic. Grating is widely used in different frameworks, such as flooring, walkways, drainage covers, and platforms, particularly in industrial environments where heavy loads are a common occurrence.

The design of grating can vary. Some common types include welded wire grating, molded grating, and press-locked grating. The choice of design often depends on factors like load capacity, environmental conditions, and intended use.

The Role of Galvanization

Galvanization refers to the process of applying a protective zinc coating to steel or iron to prevent rusting and corrosion. This is particularly important for materials exposed to harsh environments, such as moisture, salt, or industrial chemicals. The galvanization process typically involves either hot-dip galvanizing, where steel is submerged in molten zinc, or electro-galvanizing, which employs an electric current to facilitate zinc deposition.

The protective layer formed by galvanization not only extends the life of the material but also reduces maintenance costs associated with corrosion-related damage. In a world where sustainability and cost-effectiveness are paramount, the use of galvanized steel is becoming increasingly prevalent.

Benefits of Galvanized Steel Grating

1. Durability Galvanized steel grating exhibits exceptional resistance to deterioration. The zinc coating effectively shields the underlying steel from moisture and corrosive elements, making it ideal for outdoor applications or environments prone to chemical exposure.

grating galvanized

2. Low Maintenance One of the standout advantages of galvanized steel grating is its low maintenance requirement. The protective zinc layer significantly reduces the frequency of repairs and replacements, translating into long-term cost savings.

3. Versatile Applications Galvanized steel grating is suitable for various applications, including walkways, platforms, drainage covers, and even in areas with heavy vehicular traffic. The combination of strength and lightweight design makes it easy to install while ensuring safety and efficiency.

4. Safety Features The open surface design helps prevent water accumulation, mitigating slip hazards. Additionally, the material can be designed with serrated patterns or other textures to enhance traction, further improving workplace safety.

5. Recyclability As societies strive towards greener practices, the recyclability of materials becomes a significant factor. Galvanized steel can be recycled without degrading its properties, contributing to a circular economy.

Considerations When Choosing Grating

While there are numerous benefits to using galvanized steel grating, certain factors must be considered during the selection process.

- Load Capacity It is crucial to assess the expected load requirements for the specific application to ensure that the chosen grating type can support it without compromising safety. - Environmental Factors Understanding the environment in which the grating will be used can inform choices related to thickness, surface patterns, and galvanization methods to optimize performance.

- Installation Costs Although galvanized steel grating can be cost-effective in the long run, initial installation costs should be factored into the overall budget.

Conclusion

In summary, grating made from galvanized steel presents an impressive combination of durability, low maintenance, and versatile applications, making it an excellent choice for various construction and industrial needs. As the demand for robust, sustainable materials continues to grow, understanding the benefits and considerations surrounding galvanized steel grating can empower decision-makers to create safer and more efficient environments. The strategic incorporation of these materials not only enhances project outcomes but also advocates for long-lasting, eco-friendly practices in the industry.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025