- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

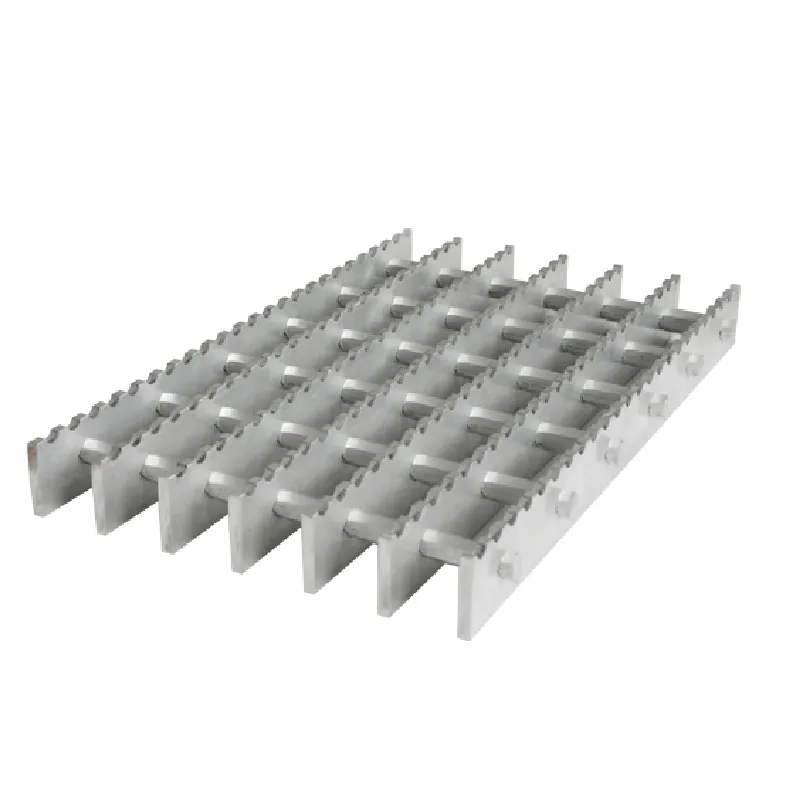

Durable Grating Floor Plates for Enhanced Safety and Stability in Various Environments

The Evolution and Importance of Grating Floor Plates in Modern Construction

Grating floor plates have become essential components in modern construction and industrial applications. With their durability, versatility, and efficiency, these materials are widely used in various sectors including manufacturing, energy, and commercial buildings. This article delves into the characteristics, applications, and benefits of grating floor plates.

Understanding Grating Floor Plates

Grating floor plates are typically made from steel, aluminum, or fiberglass. They consist of a series of parallel bars that create a grid-like surface, allowing for drainage and ventilation while still providing structural support. The gaps between the bars can be designed according to specific requirements, making them ideal for environments needing light, air, or liquid passage.

One of the striking features of grating floor plates is their ability to bear heavy loads. This quality makes them suitable for industrial settings where heavy machinery and equipment are used. Manufacturers often employ advanced engineering techniques to ensure that these plates can withstand the rigors of daily operations without compromising safety.

Applications Across Industries

Grating floor plates find extensive use across several industries. In the construction sector, they're favored for walkways, platforms, and stairways. The ability of grating to minimize slip hazards while allowing for water drainage makes it a preferred choice for outdoor applications, such as in parks or recreational areas. Additionally, grating is often utilized in wastewater treatment facilities where ensuring consistent drainage is crucial.

In the manufacturing industry, grating floor plates are commonly seen in facilities with heavy machinery. Workers benefit from the added safety features, as the non-slip surfaces reduce the risk of accidents. Moreover, the ability to customize grating layouts means that manufacturers can adapt their production floors to suit specific workflow requirements, thereby optimizing efficiency.

The energy sector also capitalizes on grating floor plates, especially in refineries, power plants, and offshore oil rigs

. In these settings, the ability to withstand corrosive environments is paramount, and the use of materials such as galvanized steel or aluminum ensures longevity and reduces maintenance costs.grating floor plate

Benefits of Grating Floor Plates

The strategic advantages of grating floor plates extend beyond just load-bearing capabilities. One of the most significant benefits is their lightweight nature. Despite their robust performance, these plates are lighter than solid flooring options, which simplifies installation and reduces transportation costs.

Ventilation is another crucial advantage offered by grating floor plates. Their design allows for optimal airflow, making them suitable for environments where ventilation is critical, such as data centers and laboratories. Effective airflow reduces heat buildup and minimizes the need for additional cooling systems, which can lead to significant energy savings in the long run.

Additionally, maintenance is relatively uncomplicated with grating floor plates. Their open design prevents debris accumulation, leading to fewer obstructions and easier cleaning processes. This efficiency minimizes downtime and allows industries to focus on their core operations rather than facility upkeep.

Future Trends

As industries evolve, so too will the design and application of grating floor plates. Innovations in materials science are paving the way for the development of even more resilient and sustainable options. For instance, the integration of composite materials may provide enhanced durability while lightening the environmental footprint of construction practices.

Moreover, the growing emphasis on safety and ergonomics is leading to the advancement of non-slip coatings and modular grating systems that can be easily replaced or adjusted. The future landscape promises to see grating floor plates becoming even more versatile, catering to the diverse and dynamic needs of modern industries.

Conclusion

Grating floor plates are indispensable in the landscape of contemporary construction and industry. Their strength, versatility, and efficiency make them vital for enhancing safety and functionality in various applications. As we look to the future, continued innovation in materials and designs will ensure that grating floor plates remain at the forefront of architectural and industrial advancements. Embracing these changes will surely pave the way for safer, more sustainable practices in construction and facility management.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025