- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

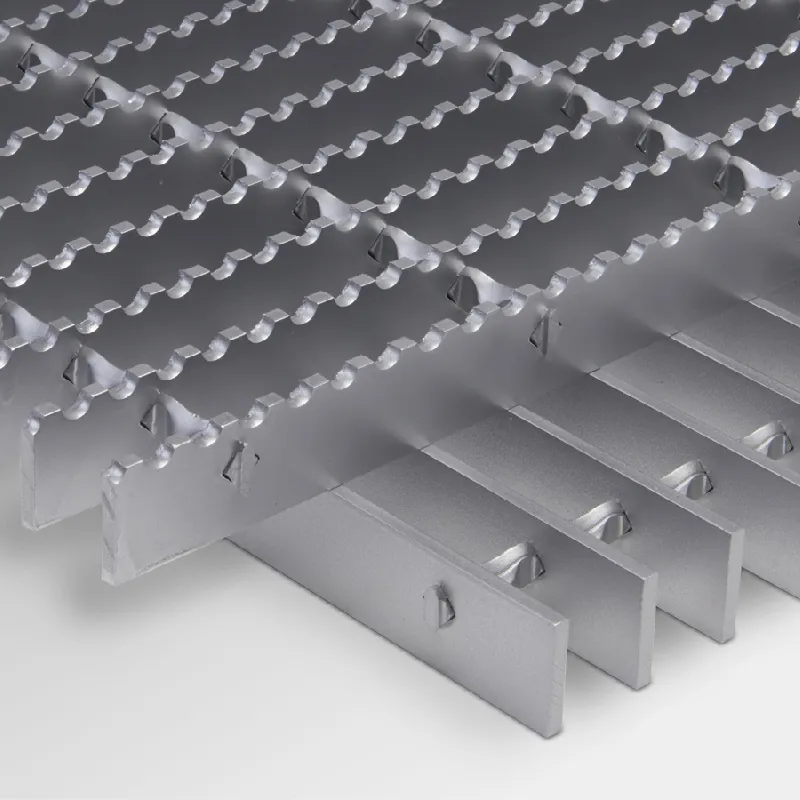

Equivalent Weight Calculation for 32x5 Grating Specifications and Performance

Understanding Grating The Importance of Weight in Selection

Grating is an essential component in various industrial and architectural applications, serving multiple functions including safety, drainage, and ventilation. Among the many specifications that need to be considered when selecting grating, weight is a crucial factor that often influences performance, durability, and cost-effectiveness. This article focuses on grating, particularly a type referred to as grating 32x5, and examines the significance of its weight in practical applications.

What is Grating 32x5?

The term grating 32x5 typically refers to a specific design of grating where the dimensions indicate the spacing and thickness of the bars 32 mm represents the distance between the bars, while 5 mm indicates the thickness of the bars themselves. This design is commonly used in environments requiring a robust solution for foot traffic or heavy machinery, as it strikes a balance between load-bearing capability and visibility.

The Role of Weight in Grating Selection

Weight plays a critical role in the selection of grating for various applications. Heavier grating options, for instance, generally imply a thicker and more resilient material, which can bear heavier loads. In contrast, lighter grating may be easier to handle and install but could lead to concerns about load capacity and lifespan. The weight of grating not only affects how it is shipped and installed but also its long-term performance in different environments.

1. Load-Bearing Capacity The weight of grating often correlates directly to its ability to support loads. Heavier grating tends to use thicker bars made from stronger materials, which can absorb and dissipate the stress from impacts and weight more effectively. For applications in factories, warehouses, or outdoor platforms, selecting the right weight is vital to prevent structural failure.

grating 32x5 weight

2. Material Choice The type of material used in manufacturing grating significantly influences its weight. Common materials include steel, aluminum, and fiberglass. Steel grating is considerably heavier but offers exceptional strength and longevity, making it suitable for heavy-duty applications. Aluminum grating, while lighter, provides corrosion resistance and may be preferable in environments exposed to moisture. Fiberglass grating is lightweight and non-corrosive, often utilized in chemical plants and coastal areas but may not match the load-bearing capability of steel.

3. Installation Efficiency The weight of the grating impacts the complexity of installation. Lighter grates can be easier to handle, which potentially reduces labor costs during installation. In contrast, heavy grates may require more manpower or lifting equipment, increasing both time and financial investments.

4. Transportation Costs Weight is an essential consideration in shipping and logistics. Heavier grating means higher transportation costs, which can impact the overall budget of a project. Opting for a lighter yet suitable alternative can help manage these expenses while ensuring compliance with safety and performance standards.

5. Integration with Other Materials In many projects, grating is integrated with other structural components. Understanding the weight of grating can aid in maintaining balance and structural integrity when combined with supports, stairs, or platforms.

Conclusion

In summary, the weight of grating, particularly types like grating 32x5, is a multifaceted aspect that influences various stages of production, installation, and maintenance. As industries evolve and demand materials that are not only strong but also economically feasible, understanding the relationship between weight, capacity, and application becomes increasingly relevant. By carefully considering weight alongside other factors, architects, engineers, and project managers can make informed decisions that enhance both safety and effectiveness in their grating selections.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025