- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

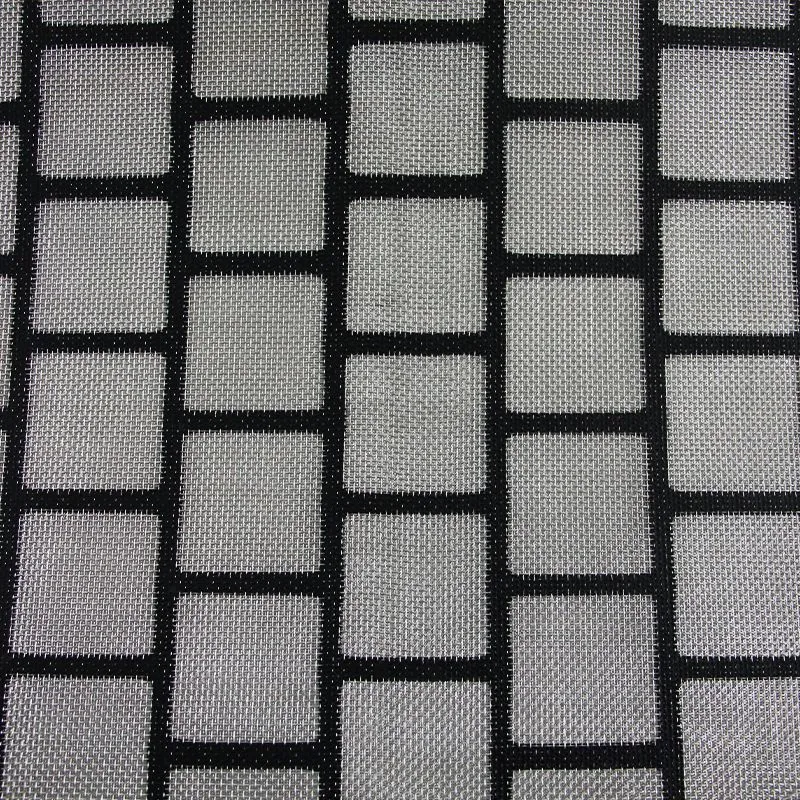

galvanized steel treads

Galvanized Steel Treads Enhancing Safety and Durability in Industrial Applications

In today's fast-paced industrial environments, safety and durability are paramount. One crucial element that plays a significant role in ensuring both is the use of galvanized steel treads. These specialized treads have become an essential feature in a variety of applications, from commercial stairways to platforms and walkways. This article explores the benefits, applications, and characteristics of galvanized steel treads, highlighting their importance in maintaining secure and efficient operational spaces.

Galvanized steel treads are made from steel that has been coated with a layer of zinc through the galvanization process. This zinc layer protects the underlying steel from corrosion, making galvanized steel an excellent choice for environments that may be exposed to moisture, chemicals, or other corrosive elements. The galvanization process not only extends the lifespan of the steel but also ensures that the treads remain robust and reliable under heavy foot traffic and rigorous mechanical use.

One of the most significant advantages of galvanized steel treads is their enhanced safety features. Many industrial settings involve the movement of employees and equipment, which can lead to slips and falls if walking surfaces are not adequately prepared. Galvanized steel treads can be designed with various surface textures and patterns that provide increased traction. This is especially crucial in wet or hazardous conditions, where traditional materials might fail to deliver adequate grip. The ability to customize the design of these treads allows for compliance with safety standards, ensuring that workplaces remain secure for employees.

galvanized steel treads

Another notable feature of galvanized steel treads is their high load-bearing capacity. In industrial environments, treads must support not only the weight of personnel but also heavy machinery and equipment. Galvanized steel, noted for its strength and resilience, effectively meets these demands. This makes them suitable for a wide range of applications, including warehouses, factories, and commercial buildings. The durability of galvanized steel treads results in less frequent replacements and repairs, translating into long-term cost savings for businesses.

Galvanized steel treads also offer versatility in design and application. They can be manufactured in various sizes, thicknesses, and configurations to suit specific needs. Common types include angle treads, planks, and pressed plates, each designed for different applications. For example, angle treads are often used for stairs, while plank treads can be utilized for creating large walkways. This flexibility enables engineers and architects to incorporate them into various structures seamlessly, enhancing the overall functionality and aesthetics of the environment.

Environmental considerations are also an essential factor in the choice of materials in construction and industrial settings. Galvanized steel is recyclable, contributing to sustainable practices in construction. As industries strive to minimize their environmental footprint, opting for eco-friendly materials like galvanized steel aligns with these goals. This aspect not only supports environmental sustainability but also improves a company's image as a responsible and forward-thinking organization.

In conclusion, galvanized steel treads are indispensable in enhancing safety, durability, and functionality across various industrial applications. Their resistance to corrosion, customizable designs, and high load-bearing capacity make them an ideal choice for environments that demand both performance and reliability. By integrating galvanized steel treads into their operations, businesses can protect their workforce while also ensuring longevity and efficiency in their infrastructure. As industries continue to evolve, the importance of incorporating superior materials like galvanized steel treads will only grow, paving the way for safer and more efficient work environments.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025