- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

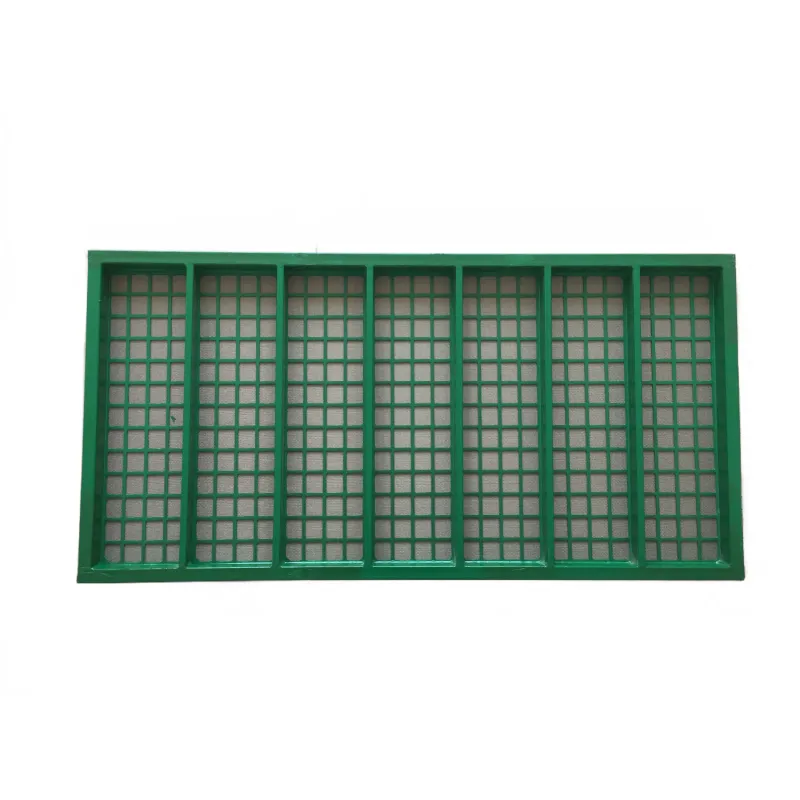

galvanized steel grid

The Advantages of Galvanized Steel Grid A Comprehensive Overview

In the realm of modern construction and structural engineering, galvanized steel grids have emerged as a popular choice due to their unique blend of strength, durability, and resistance to corrosion. These grids, typically made from steel that has been coated with a layer of zinc, are used in a variety of applications, from flooring systems to walkways, and even in industrial environments. This article explores the benefits of galvanized steel grids, their applications, and why they are a reliable choice for both commercial and residential projects.

What is Galvanized Steel?

Galvanization is a process that involves applying a protective zinc coating to steel in order to prevent rusting and corrosion. This layer of zinc serves as a sacrificial barrier; even if the surface of the steel is scratched, the zinc will corrode before the underlying metal does. This process significantly increases the lifespan of the steel, making it an ideal material for outdoor and high-moisture environments.

Durability and Strength

One of the primary reasons for the popularity of galvanized steel grids is their exceptional durability. These grids are engineered to withstand heavy loads, making them ideal for industrial applications such as manufacturing floors, loading docks, and outdoor platforms. Galvanized steel is also highly resistant to impact, allowing it to maintain its structural integrity even under challenging conditions.

Moreover, the strength of galvanized steel grids contributes to their safety features

. Used in walkways and staircases, these grids provide a robust surface that minimizes the risk of slips and falls. The open grid design allows for excellent drainage, reducing the likelihood of water pooling and creating hazards.Corrosion Resistance

galvanized steel grid

Galvanized steel grids are specifically designed to resist corrosion caused by moisture, chemicals, and varying environmental conditions. The zinc coating protects the underlying steel from rust and degradation, giving these grids a significantly longer lifespan compared to uncoated steel or other materials like aluminum. This characteristic is especially advantageous in coastal areas or environments that experience heavy precipitation or chemical exposure.

Low Maintenance Requirements

The maintenance of galvanized steel grids is relatively effortless compared to other materials. Due to the protective nature of the zinc coating, these grids do not require regular painting or treatment. This not only saves time and labor costs but also reduces the overall lifecycle costs of the structure. Generally, a well-maintained galvanized steel grid can last for several decades without requiring significant repairs or replacements.

Versatile Applications

Galvanized steel grids are versatile and can be used in various applications across different industries. In commercial settings, they are often employed as flooring for aisles, stairways, and platforms. In industrial environments, they provide safe walkways and are often used in equipment platforms and machine guarding. The agricultural sector also benefits from these grids, utilizing them in livestock facilities and storage areas.

Additionally, their aesthetic appeal makes them suitable for architectural designs where visibility and light penetration are desired. Galvanized steel grids can be used in decorative installations, providing both function and style.

Conclusion

Galvanized steel grids are a reliable and practical choice for a wide range of applications. With their outstanding durability, corrosion resistance, low maintenance, and versatile uses, they stand out as a superior option in modern construction. As industries continue to seek materials that offer both strength and longevity, galvanized steel grids will undoubtedly remain a staple in the market, ensuring safety and efficiency for years to come. Whether for industrial, commercial, or residential use, the advantages of galvanized steel grids make them a wise investment in any construction project.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025