- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

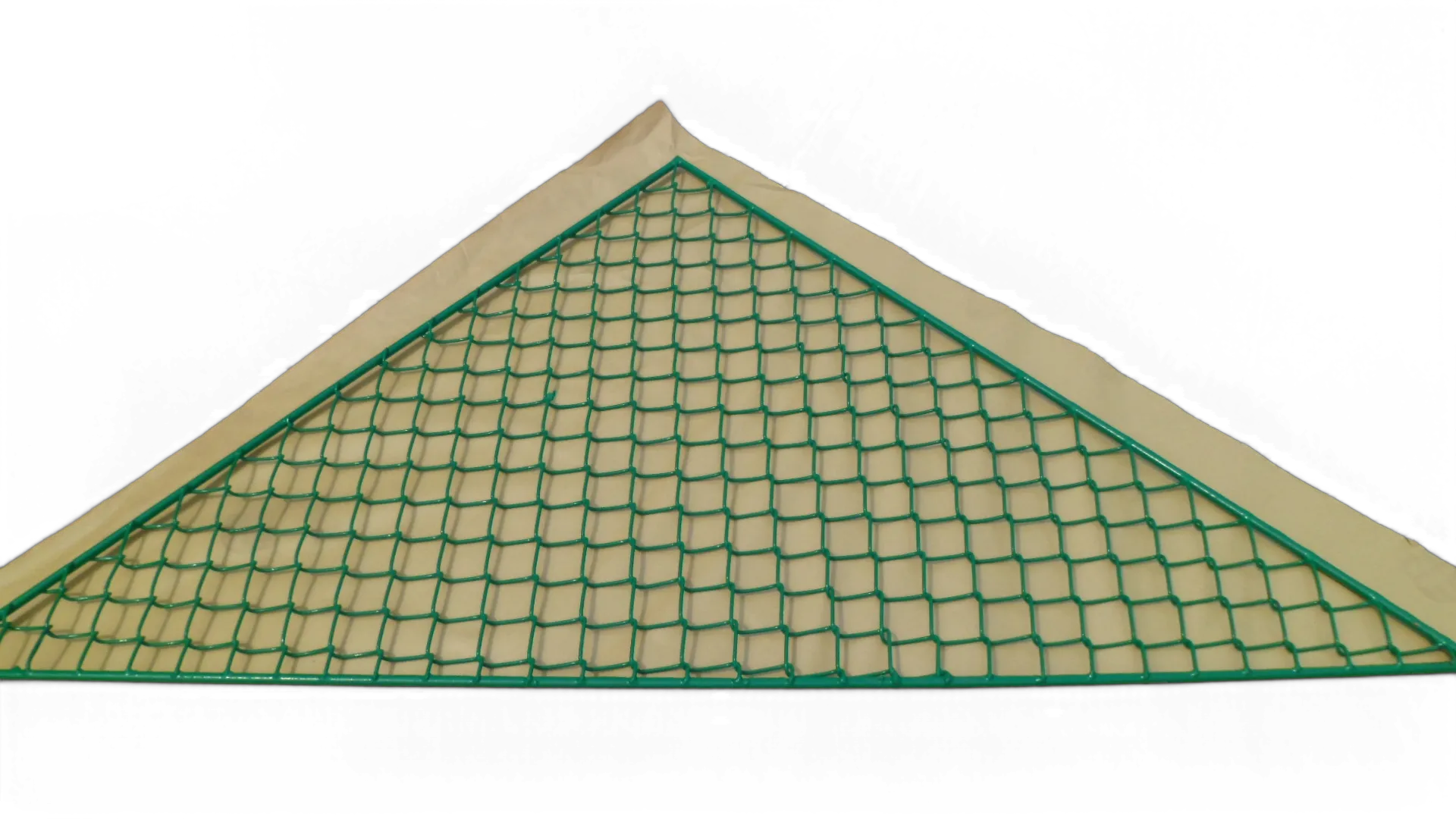

galvanized steel grid

Understanding Galvanized Steel Grids Applications and Benefits

Galvanized steel grids have become essential components in various industries due to their durability, strength, and corrosion resistance. The process of galvanization, where steel is coated with a layer of zinc, enhances the metal's ability to withstand harsh environmental conditions. This article explores the characteristics, applications, and benefits of galvanized steel grids.

What is Galvanized Steel?

Galvanized steel is produced by applying a protective zinc coating to iron or steel, which prevents rusting and increases the lifespan of the material. The zinc acts as a sacrificial barrier; even if the coating is scratched or damaged, the exposed steel is protected from corrosion, as zinc reacts with oxygen more readily than iron. This makes galvanized steel exceptionally valuable for outdoor and industrial applications where exposure to moisture and air is a concern.

Characteristics of Galvanized Steel Grids

Galvanized steel grids are typically composed of interconnected steel rods or bars arranged in a network pattern. These grids can vary in size, spacing, and thickness, depending on their intended use. The galvanization process not only provides a protective coating but also gives the steel grid a smooth finish, which aids in cleaning and maintenance. The light weight and high strength-to-weight ratio of galvanized steel grids make them versatile and easy to handle.

Applications of Galvanized Steel Grids

galvanized steel grid

1. Construction and Infrastructure Galvanized steel grids are commonly used in construction for stair treads, walkways, and platforms due to their slip-resistant surface. Their load-bearing capability makes them suitable for bridges, flooring systems, and even supporting structures in buildings.

2. Agriculture In agricultural settings, galvanized grids can serve as flooring for livestock enclosures, providing safety and hygiene. They allow waste to fall through while ensuring animals have a stable surface. Moreover, these grids are often utilized in the construction of silos and storage facilities for grain.

3. Mining and Heavy Industry The durability of galvanized steel grids makes them a perfect choice for mining applications. They are used for walkways in mines and as support structures in various heavy industrial processes, where resilience against harsh conditions is paramount.

4. Environmental Applications Galvanized steel grids also find use in environmental applications such as drainage systems and stormwater management systems. They help facilitate proper water flow while withstanding the corrosive effects of chemicals often found in runoff.

Benefits of Using Galvanized Steel Grids

The primary advantage of using galvanized steel grids is their extended lifespan due to the corrosion protection provided by the zinc coating. They require minimal maintenance, leading to lower long-term costs compared to non-galvanized alternatives. Additionally, galvanized steel grids offer excellent strength and stability, making them suitable for various demanding applications.

In summary, galvanized steel grids are vital components across multiple industries. Their strength, durability, and resistance to corrosion make them an ideal choice for construction, agriculture, mining, and environmental applications. As industries continue to seek materials that enhance safety and efficiency, galvanized steel grids will remain a popular and reliable option.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025