- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

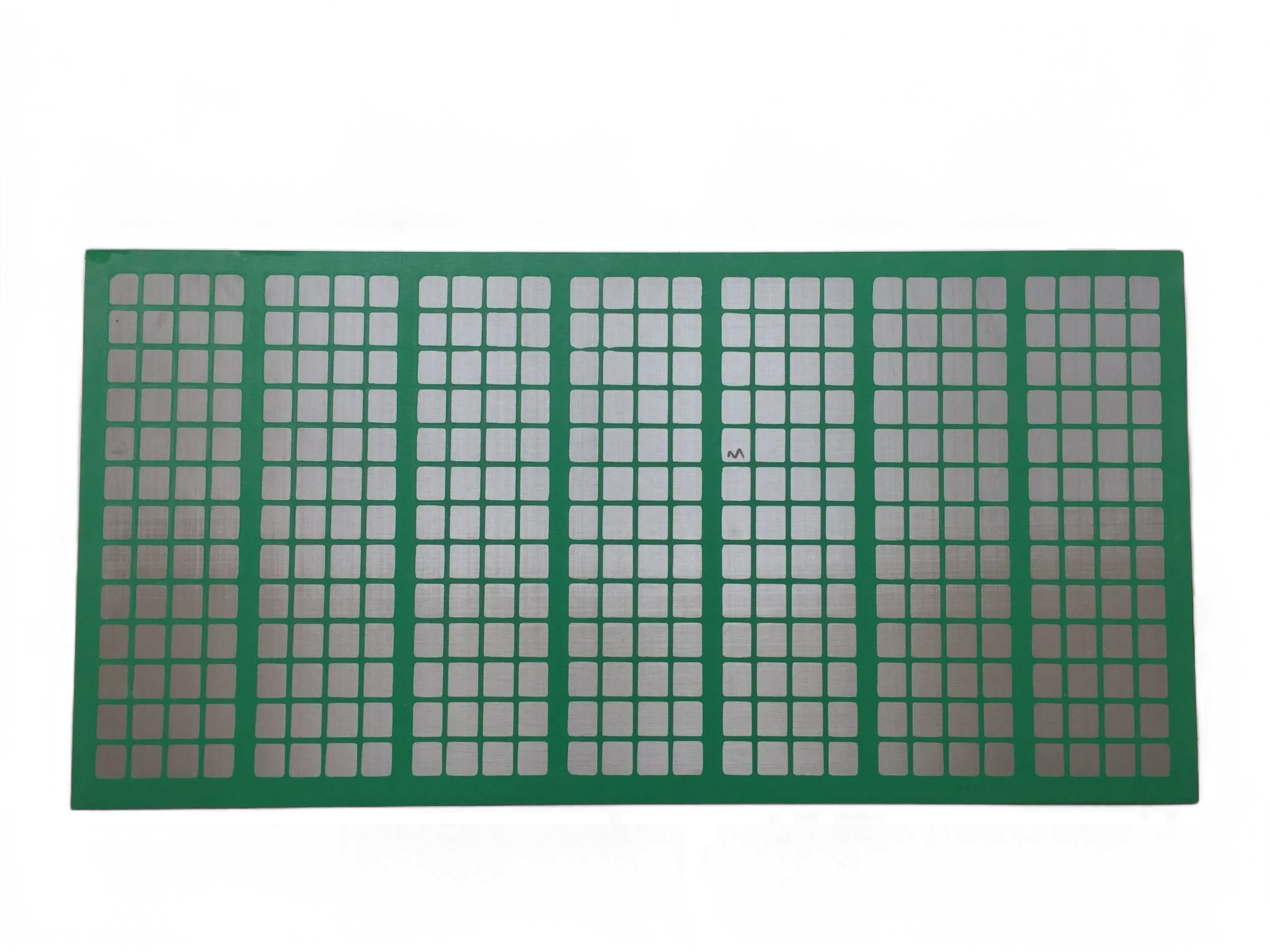

galvanized steel grating platform

Understanding Galvanized Steel Grating Platforms

Galvanized steel grating platforms have become an essential component in various industrial and commercial settings due to their strength, durability, and versatility. These platforms are made from galvanized steel, which undergoes a hot-dip galvanization process that significantly enhances their corrosion resistance and longevity. This article discusses the benefits, applications, and considerations associated with galvanized steel grating platforms.

What is Galvanized Steel Grating?

Galvanized steel grating is a type of flooring made from steel bars that are welded or mechanically joined to create a grid-like structure. The galvanization process involves coating the steel with a layer of zinc to prevent rust and degradation caused by exposure to moisture and environmental elements. This protective layer is vital for ensuring that the steel can withstand harsh conditions typically found in industrial applications.

Benefits of Galvanized Steel Grating Platforms

1. Durability One of the most significant advantages of galvanized steel grating platforms is their exceptional durability. They can support heavy loads without deforming, making them suitable for industrial operations involving heavy machinery and equipment.

2. Corrosion Resistance The galvanization process provides a protective barrier against rust and corrosion, extending the lifespan of the grating. This is especially important in environments with high humidity, chemicals, or salt exposure.

3. Safety Galvanized steel grating platforms can be designed with slip-resistant surfaces, improving safety for workers. The open grid design also allows for better drainage and reduces the risk of pooling water, which can lead to slips and falls.

4. Low Maintenance Due to their robust construction and resistance to corrosion, galvanized steel grates require minimal maintenance. Regular inspections are sufficient to ensure their durability and functionality.

Applications of Galvanized Steel Grating Platforms

galvanized steel grating platform

Galvanized steel grating platforms are widely used in various industries, including

- Manufacturing They are often used in factories for walkways, platforms, and mezzanines, where strength and reliability are paramount.

- Construction In the construction of buildings and bridges, galvanized steel grating provides essential structural support while ensuring safety.

- Wastewater Treatment Galvanized steel grating is commonly used in water treatment facilities due to its resistance to corrosive environments.

- Chemical Processing The chemical industry benefits from the durability and resistance to harsh chemicals that galvanized steel provides.

Considerations When Choosing Galvanized Steel Grating Platforms

When selecting galvanized steel grating platforms, it's essential to consider factors such as load requirements, spacing, and the environment in which the grating will be used. Customization options are available to meet specific needs, including varying thicknesses and designs to accommodate different load conditions.

Additionally, while galvanized steel provides excellent corrosion resistance, it may not be suitable for all applications, particularly those exposed to highly corrosive substances. In such cases, alternative materials like stainless steel or fiberglass grating might be more appropriate.

Conclusion

Galvanized steel grating platforms offer a robust, durable, and cost-effective solution for a wide range of applications in industrial and commercial settings. Their unique advantages, including corrosion resistance, safety features, and low maintenance requirements, make them a preferred choice for many industries. When properly selected and maintained, these platforms can provide years of reliable service, contributing to the efficiency and safety of operations.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025