- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

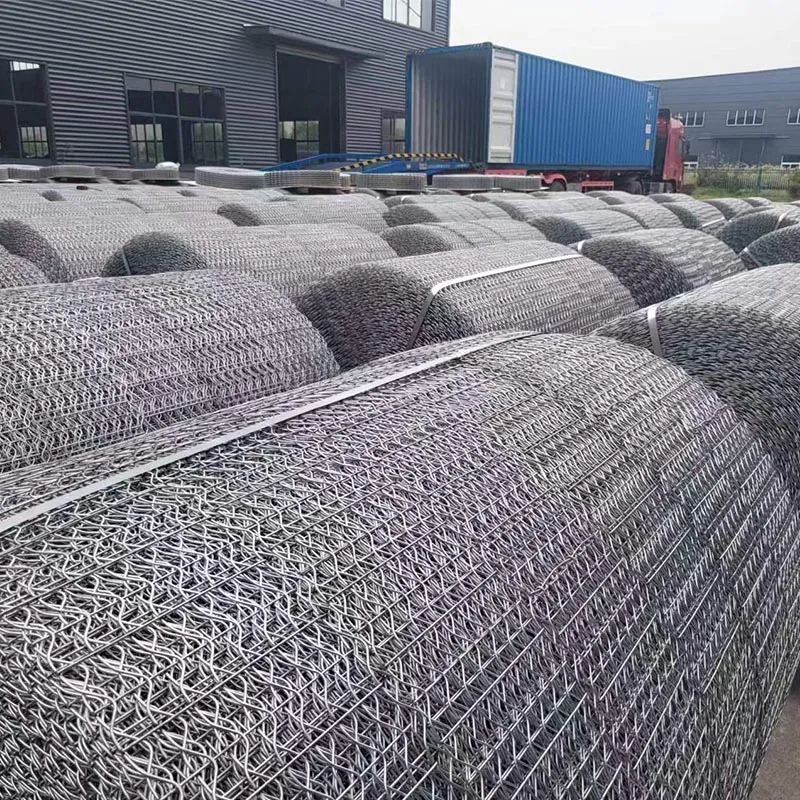

Corrosion-Resistant Galvanized Steel Plank Grating for Enhanced Durability and Safety

Understanding Galvanized Plank Grating An Essential Construction Material

In the world of construction and industrial applications, material selection plays a pivotal role in determining the durability, safety, and efficiency of a project. One such vital material that has garnered significant attention in recent years is galvanized plank grating. Known for its robustness and versatility, galvanized plank grating serves various purposes across diverse sectors, including construction, manufacturing, and wastewater management.

What is Galvanized Plank Grating?

Galvanized plank grating refers to a type of flooring system made from steel bars, which are shaped and assembled to create a grid-like structure. The term galvanized indicates that the steel has undergone a galvanization process, where it is coated with a layer of zinc to prevent rusting and corrosion. This treatment enhances the lifespan of the grating, making it suitable for both indoor and outdoor applications, especially in harsh environmental conditions.

The Manufacturing Process of Galvanized Plank Grating

The production of galvanized plank grating requires several critical steps. Initially, raw steel bars are cut into the desired lengths and widths. The bars are then arranged in a pre-defined pattern to form the grating. In some designs, the bars may be spaced apart to allow for drainage and airflow, which is particularly useful in areas prone to water accumulation.

Once assembled, the grating is subjected to the galvanization process. This involves cleaning the steel to remove any impurities and then submerging it in molten zinc. The result is a durable coating that adheres tightly to the steel, providing excellent protection against rust and environmental damage. The final product is a strong, lightweight grating that is easy to handle and install.

Advantages of Galvanized Plank Grating

1. Durability One of the most significant advantages of galvanized plank grating is its durability. The galvanized coating protects against corrosion, allowing the grating to withstand harsh weather conditions, chemical exposure, and abrasion. This resilience ensures a long service life, reducing the frequency of replacements.

galvanized plank grating

2. Safety Safety is paramount in construction and industrial settings. Galvanized plank grating is designed with safety in mind. Its slip-resistant surface minimizes the risk of accidents, making it suitable for walkways, ramps, and industrial floors. Additionally, the open design allows for excellent drainage, reducing the likelihood of water pooling and further enhancing safety.

3. Versatility Galvanized plank grating is highly versatile and can be customized to meet specific project requirements. It is available in various sizes, shapes, and load-bearing capacities, making it suitable for a wide range of applications, from walkways and platforms to heavy-duty industrial environments.

4. Cost-Effectiveness While the initial investment in galvanized plank grating may seem higher than some alternatives, its long-term value is notable. The reduced maintenance costs and extended lifespan result in lower total ownership costs over time. Additionally, the ease of installation can contribute to overall project savings.

Applications of Galvanized Plank Grating

Galvanized plank grating finds application in numerous settings. In industrial environments, it is commonly used for flooring in factories, manufacturing plants, and machinery platforms. Its ability to handle heavy loads makes it a preferred choice for areas where robust support is necessary.

In commercial buildings, galvanized plank grating serves as an effective solution for walkways, stairways, and mezzanines. Its aesthetic appeal and functional properties make it an attractive choice for both employees and customers.

Moreover, in wastewater treatment facilities, galvanized grating is utilized in walkways above tanks and pits, ensuring safety for maintenance personnel while providing durability against potential chemical exposure.

Conclusion

In summary, galvanized plank grating stands out as a reliable and versatile construction material. Its durability, safety features, and cost-effectiveness make it an excellent choice for various applications across multiple industries. By investing in galvanized plank grating, construction professionals can ensure their projects not only meet immediate needs but also stand the test of time, contributing to overall efficiency and safety in the built environment.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025