- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

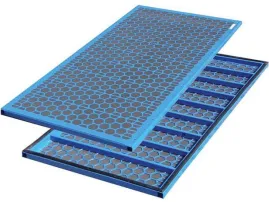

galvanized metal grating

The Versatility and Benefits of Galvanized Metal Grating

Galvanized metal grating has become increasingly popular in various industrial and commercial applications due to its durability, strength, and resistance to corrosion. This type of grating is fabricated from steel that has undergone galvanization, a process that involves coating the metal with a layer of zinc. This protective layer not only enhances the steel's lifespan but also makes it more suitable for harsh environments.

One of the most significant advantages of galvanized metal grating is its resistance to rust and corrosion. Traditional steel materials often succumb to moisture and environmental factors, leading to deterioration over time. However, galvanized grating can withstand exposure to water, chemicals, and other corrosive substances, making it ideal for use in facilities such as wastewater treatment plants, chemical processing plants, and outdoor installations.

In addition to its corrosion resistance, galvanized metal grating is known for its strength and load-bearing capacity. This makes it suitable for a variety of heavy-duty applications, including flooring, walkways, and platforms. The open design of the grating allows for quick drainage of liquids and the passage of light, contributing to a safer environment by minimizing slip hazards.

Another important benefit of galvanized metal grating is its cost-effectiveness

. While the initial purchase price may be higher than some alternatives, the long-term savings associated with reduced maintenance and replacement costs make it a wise investment. Businesses and facility managers can expect lower expenses over time as they spend less on repairs and replacements due to the longevity of galvanized grating.galvanized metal grating

Furthermore, galvanized metal grating is available in various sizes, shapes, and styles, which adds to its versatility. It can be customized to fit specific needs, whether for pedestrian foot traffic, heavy machinery, or even aesthetic applications in architectural designs. This adaptability ensures that galvanized metal grating can be used in a wide range of sectors, from manufacturing and construction to public infrastructure projects.

The installation process for galvanized grating is also straightforward, facilitating quicker project completion times. Its lightweight nature, combined with pre-manufactured options, helps reduce labor costs and minimizes on-site construction time. Once installed, the grating requires minimal upkeep, reinforcing its position as a practical choice for many organizations.

Moreover, galvanized metal grating contributes positively to environmental sustainability. The galvanization process is relatively eco-friendly, and the long lifespan of the grating means fewer resources are used for replacements. Recyclability is another factor; at the end of its life cycle, galvanized metal can be melted down and repurposed, further reducing waste.

In summary, galvanized metal grating stands out as an excellent solution for various industrial and commercial needs. Its unique combination of strength, durability, corrosion resistance, and cost-effectiveness makes it an ideal choice for projects that require resilient flooring and walkways. As industries continue to seek reliable and sustainable materials, galvanized metal grating will undoubtedly remain a top contender in the market.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025