- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

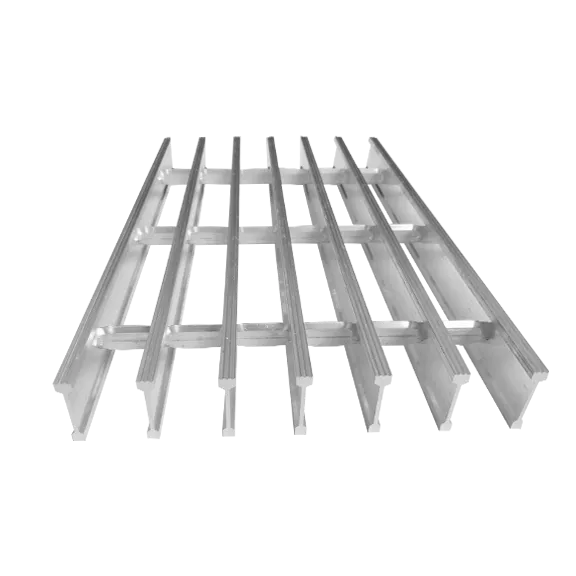

galvanized grating sizes

Understanding Galvanized Grating Sizes

Galvanized grating is a versatile and durable solution widely used in various industrial and commercial applications. It consists of a grid-like structure made from steel bars that are coated with a layer of zinc through the process of galvanization. This coating not only enhances the longevity of the grating by preventing rust and corrosion but also adds to its aesthetic appeal. One crucial aspect of utilizing galvanized grating in projects is understanding the different sizes available and their applications.

The Importance of Grating Sizes

When selecting galvanized grating, size plays a pivotal role. The size of the grating affects both its load-bearing capacity and its applicability to specific projects. Galvanized grating typically comes in various dimensions, including different thicknesses and spacing between the bars. Understanding these dimensions ensures that the right type of grating is chosen for specific loads and environmental conditions.

Common Sizes of Galvanized Grating

Galvanized grating is available in multiple sizes, which can vary based on the manufacturer. Commonly, the standard widths range from 24 inches to 48 inches, while lengths can extend up to 24 feet. The thickness of the bars can vary from 1/8 inch to 3/4 inch, depending on the intended use and load requirements.

The spacing between the bars is another critical factor. Typical spacing options include 1 inch, 1.5 inches, and 2 inches center-to-center. Narrower spacing is often used for applications requiring a smooth surface to prevent objects from falling through, while wider spacing may be acceptable where debris can pass freely, such as in drainage applications.

Load Capacities and Their Implications

Different grating sizes and configurations can support varying load capacities. For instance, heavier and thicker grating can bear more weight, making them suitable for industrial applications like walkways, platforms, and catwalks. On the other hand, lighter grating may be adequate for applications such as ventilation covers or lightweight platforms.

galvanized grating sizes

Understanding the load requirements for a specific application is vital. The load capacity is typically influenced not only by the size and thickness of the grating but also by the span—how far it is supported. Accurate calculations must be made to ensure safety and efficiency in design.

Applications of Galvanized Grating

Galvanized grating finds application across various sectors, including construction, manufacturing, food processing, and wastewater treatment. In construction, it is often used for flooring, stair treads, and walkways. In industrial settings, it serves as a platform to facilitate personnel access to machinery and equipment while ensuring safe passage.

Moreover, the food processing industry relies on galvanized grating for cleanliness and hygiene, as its smooth surface is easy to clean and does not retain contaminants. In wastewater treatment, grating allows for efficient drainage while providing structural support for equipment.

Customization and Special Sizes

While standard sizes can accommodate a broad range of needs, many manufacturers offer customized sizing options. Custom sizes are particularly beneficial for unique projects that do not fit standard dimensions. This flexibility is essential for ensuring that the grating meets specific dimensional and load-bearing requirements.

Conclusion

In conclusion, understanding galvanized grating sizes is vital in selecting the right type for any given application. Various sizes, thicknesses, and spacing options are available, each tailored to meet specific structural and load demands. By assessing the requirements of the project and consulting with manufacturers, architects, and engineers, one can ensure the selection of the appropriate galvanized grating that will not only serve its intended purpose but also provide longevity and safety within the operational environment. As industries continue to evolve, the need for durable, reliable, and customizable solutions like galvanized grating will remain a fundamental aspect of structural design and engineering.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025