- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

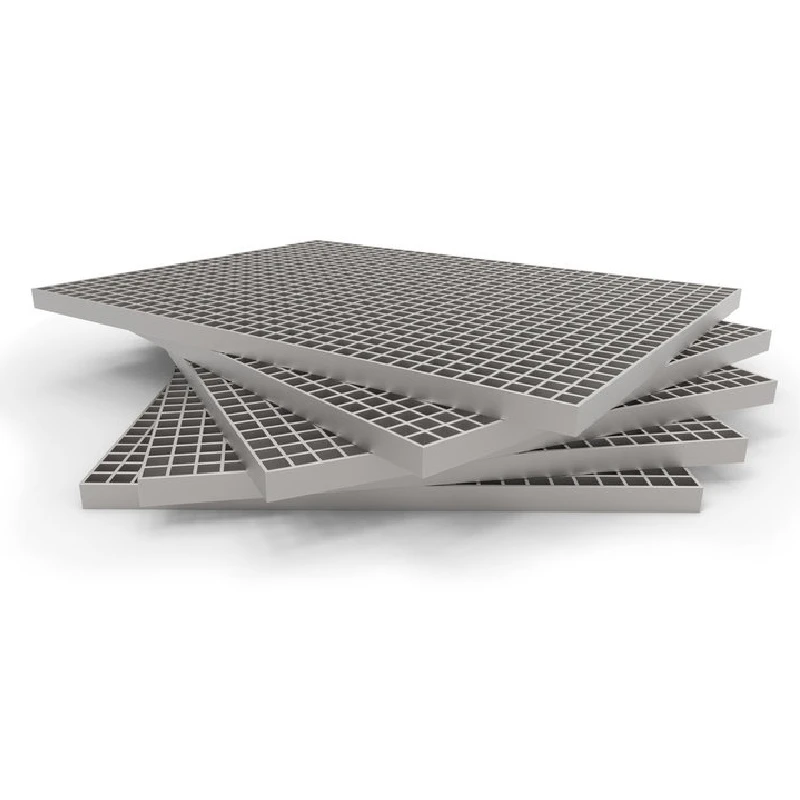

Guide to Galvanized Grating Dimensions and Specifications for Various Applications

Understanding Galvanized Grating Sizes

Galvanized grating is an essential component in various industrial applications, widely used for flooring, walkways, platforms, and safety barriers. Its unique properties, including durability, strength, and corrosion resistance, make galvanized grating a preferred choice in environments where exposure to harsh elements is a concern. This article delves into the different sizes of galvanized grating, their applications, and why understanding these dimensions is crucial for your project.

What is Galvanized Grating?

Galvanized grating is made from steel that has been coated with a layer of zinc to prevent rusting and corrosion. The process of galvanization increases the lifespan of the grating, making it suitable for outdoor and industrial use. Galvanized grating features an open grid pattern that allows for water drainage and light penetration while providing traction and support.

Common Sizes of Galvanized Grating

Galvanized grating comes in various sizes, typically categorized by the width and height of the bearing bars, as well as the overall dimensions of the panels. The most common sizes include

1. Bearing Bar Sizes The most popular bearing bar sizes range from 0.5 inches to 2 inches in height and 0.25 to 0.5 inches in width. The choice of bearing bar size directly affects the load capacity and strength of the grating.

2. Spacing The spacing between the bearing bars can vary, usually from 1 inch to 4 inches, depending on the intended application. Closer spacing provides better support for smaller items and increases safety, while wider spacing allows for better drainage.

3. Panel Dimensions The standard panel sizes for galvanized grating usually come in 3 feet by 20 feet or 4 feet by 12 feet. However, custom sizes can often be manufactured to meet specific project requirements.

4. Thickness Galvanized gratings are also available in various thicknesses, typically ranging from 1/8 inch to 1 inch. Thicker gratings offer higher load-bearing capacity, which is vital for heavy-duty applications.

5. Material Composition While steel is the most common material used for galvanized grating, there are also aluminum and fiberglass options available. Each material has its own weight, corrosion resistance, and load capacity characteristics.

galvanized grating sizes

Applications of Galvanized Grating Sizes

The diverse sizes of galvanized grating make it suitable for a range of applications

- Industrial Flooring Strong and durable, galvanized grating is ideal for factory floors, storage facilities, and outdoor platforms where heavy machinery or foot traffic is present.

- Walkways and Stairways The slip-resistant surfaces offered by galvanized grating make it perfect for walkways and staircases, ensuring safety in both industrial and commercial environments.

- Drainage Systems With excellent drainage properties, galvanized grating is often used in trenches and drainage systems to manage water runoff effectively.

- Safety Barriers Galvanized grating can also be used in the construction of safety barriers around construction sites, road works, and elevated platforms to prevent accidental falls.

Importance of Choosing the Right Size

Selecting the appropriate size of galvanized grating is critical for the success of any project. The right size will ensure sufficient load-bearing capacity while maintaining safety. For instance, using grating that is too small may lead to structural failure, posing risks to workers and equipment. On the other hand, choosing oversized gratings can result in unnecessary costs and weight.

Additionally, consulting with manufacturers or industry experts can help you understand load capacities, spacing, and material options. This ensures that the galvanized grating you select meets your specific needs and regulatory standards.

Conclusion

Galvanized grating is a versatile, durable, and essential material used across various industries. By understanding the different sizes available and their respective applications, you can make informed decisions that enhance safety and efficiency in your projects. Whether for industrial flooring, walkways, or safety barriers, selecting the right galvanized grating size can make all the difference in the success of your endeavors.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025