- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

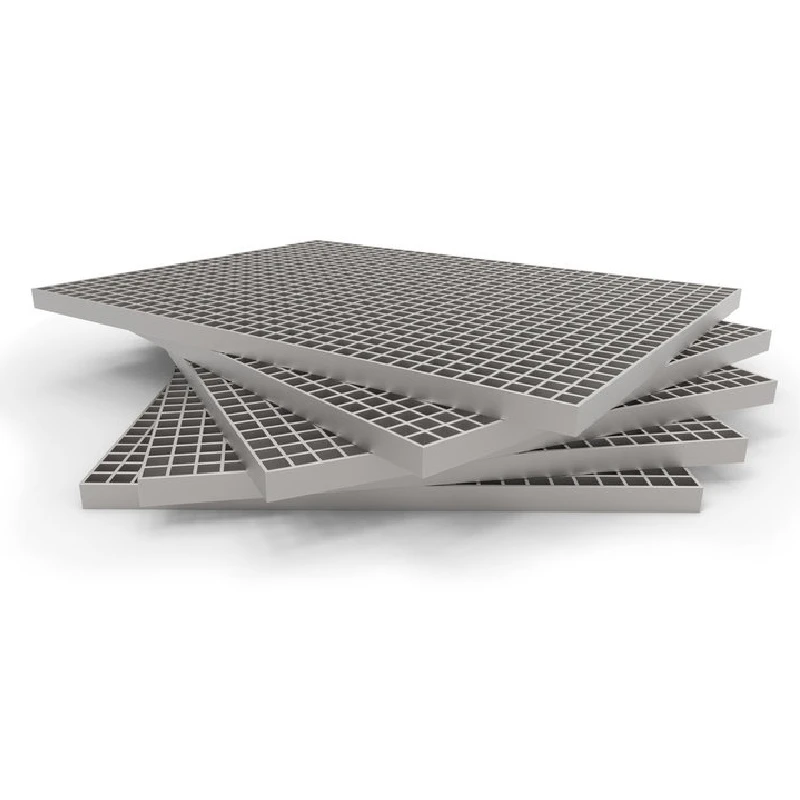

galvanized grating price

Understanding the Pricing of Galvanized Grating

Galvanized grating has become an essential material in various industrial applications due to its durability, strength, and resistance to corrosion. It is commonly used in walkways, platforms, and as support systems in environments where exposure to chemicals and weathering is a concern. With rising demand, understanding the factors influencing galvanized grating prices becomes crucial for businesses and consumers alike.

What is Galvanized Grating?

Galvanized grating consists of steel bars welded together in a grid pattern and then coated with a layer of zinc to enhance its corrosion-resistant properties. This galvanization process ensures that even when exposed to the harshest conditions, the underlying steel remains protected, thus extending the lifespan of the grating. Different types of galvanizing processes, such as hot-dip or electro-galvanizing, can affect the final properties and pricing of the grating.

Factors Influencing Galvanized Grating Prices

1. Material Costs The primary factor influencing the price of galvanized grating is the cost of raw materials. Steel prices can fluctuate based on market demand, supply chain issues, and tariffs or trade policies affecting steel imports and exports. Increased steel prices generally lead to higher grating prices.

2. Manufacturing Process The method used to fabricate the grating can also impact its price. Hot-dip galvanizing, while providing superior protection, is often more costly compared to electro-galvanizing. Moreover, the complexity of the manufacturing process—such as the thickness of the bars, spacing, and customizations—will reflect in the final price of the product.

galvanized grating price

3. Size and Specifications Galvanized grating comes in various sizes and thicknesses, designed to accommodate different loads and applications. Custom sizes or specific load-bearing requirements generally incur additional costs due to the need for specialized manufacturing processes.

4. Market Demand Economic conditions play a significant role in determining the demand for galvanized grating. During construction booms or industrial expansions, prices may rise due to increased demand. Conversely, during economic downturns, prices may stabilize or decrease as demand wanes.

5. Transportation and Logistics The geographical location also affects the cost of galvanized grating. Shipping and handling fees can significantly add to the overall cost, especially if the product is being transported over long distances. Typically, companies based closer to manufacturing plants may benefit from lower transportation costs.

6. Supplier Reputation Established suppliers with a good track record may charge higher prices due to their reliability and the quality of their products. Businesses often prefer these suppliers for the assurance that their materials will meet industry standards and last longer.

Conclusion

Understanding the pricing of galvanized grating involves considering various factors, from material costs to market demand and logistics. For consumers and businesses, it is essential to conduct comprehensive market research and compare multiple suppliers to obtain the best value for money. By taking into account all the influencing factors—material quality, manufacturing processes, and supplier reliability—buyers can make informed decisions and secure galvanized grating that meets their needs without breaking their budget. As industries continue to expand, the importance of high-quality, cost-effective galvanized grating will undoubtedly remain a priority.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025