- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Benefits of Using Galvanized Drainage Grates for Effective Water Management and Longevity

The Importance of Galvanized Drainage Grates in Modern Infrastructure

In the realm of urban planning and civil engineering, drainage systems play a pivotal role in managing water flow, preventing flooding, and ensuring the longevity of infrastructure. Among the various components of these systems, galvanized drainage grates stand out for their durability, efficiency, and versatility. This article explores the significance of galvanized drainage grates, highlighting their advantages, applications, and maintenance tips.

What are Galvanized Drainage Grates?

Galvanized drainage grates are specially designed covers placed over drainage channels, culverts, and stormwater inlets. They are made from iron or steel coated with a layer of zinc through a process known as galvanization. This protective coating serves two primary purposes it prevents rust and corrosion, ensuring the material's longevity, and provides a strong, durable surface capable of withstanding heavy loads.

Advantages of Galvanized Drainage Grates

1. Durability and Longevity One of the most significant advantages of galvanized drainage grates is their exceptional durability. The galvanization process protects the metal from corrosion, which is particularly important in environments that are frequently exposed to moisture, chemicals, and varying temperatures. This longevity translates to lower replacement costs and reduced environmental impact, as fewer resources are needed for upkeep.

2. Load-Bearing Capacity Galvanized grates are designed to support heavy loads, making them ideal for use in busy urban environments, roads, parking lots, and industrial areas. They can withstand the weight of vehicles and heavy equipment without compromising their structural integrity, ensuring that drainage systems remain functional under stress.

3. Versatility These grates come in various designs, sizes, and load ratings, making them suitable for a wide range of applications, from residential areas to commercial developments. Whether used in pedestrian walkways, driveways, or industrial sites, galvanized drain grates can be tailored to meet specific requirements.

4. Safety Safety is a paramount concern in any construction project, and galvanized drainage grates contribute to public safety by providing secure footing for pedestrians and vehicles. They are available in slip-resistant designs, which help reduce the risk of accidents, particularly in wet conditions.

5. Cost-Effectiveness Despite a slightly higher initial investment compared to other materials, the long-term savings associated with galvanized drainage grates make them a cost-effective choice. Their durability means reduced maintenance and replacement costs, while also minimizing the environmental footprint associated with frequent installations of less durable alternatives.

Applications of Galvanized Drainage Grates

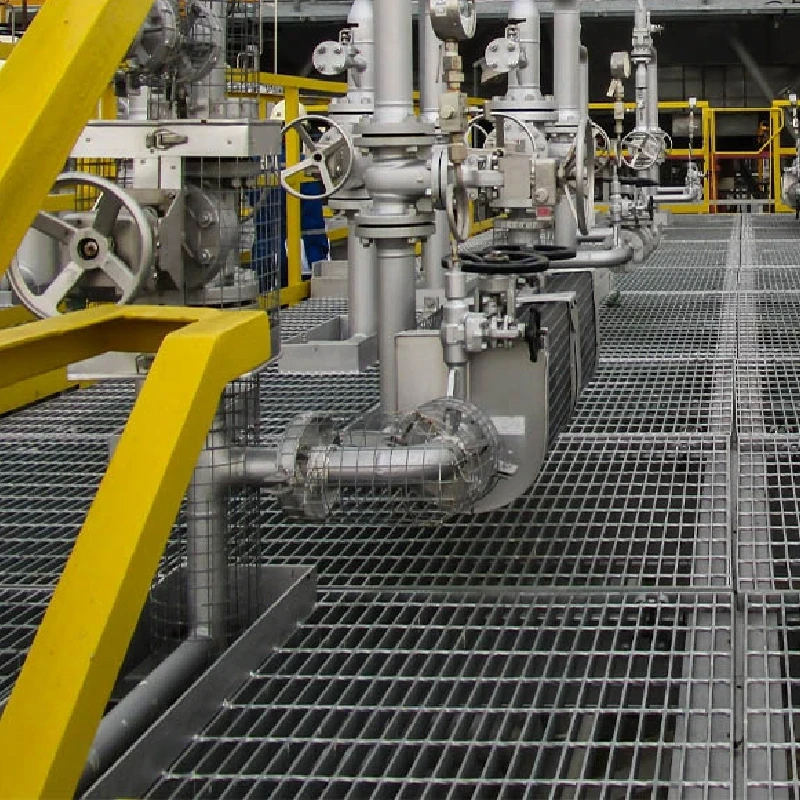

galvanized drainage grates

Galvanized drainage grates are used in a myriad of applications

- Roadways and Parking Lots They are commonly found in roads and parking lots, aiding in the efficient disposal of rainwater and preventing flooding. - Commercial Properties Businesses utilize them around buildings to manage stormwater runoff, ensuring safety and compliance with local regulations.

- Public Parks and Recreation Areas They provide drainage solutions in parks, playgrounds, and other recreational areas, maintaining aesthetic quality while enhancing safety.

- Industrial Sites In manufacturing and warehousing environments, they facilitate the proper drainage of water, preventing accumulation and potential hazards.

Maintenance of Galvanized Drainage Grates

While galvanized drainage grates are low maintenance due to their corrosion resistance, regular inspections are essential to ensure optimal performance. Here are a few maintenance tips

1. Regular Cleaning Debris, leaves, and sediment can accumulate on grates, potentially obstructing drainage. Regular cleaning prevents clogs and ensures proper water flow.

2. Inspection for Damage Periodic inspections help identify signs of wear or damage. Early detection of issues can prevent more significant problems down the line.

3. Reapplication of Coating In some cases, re-coating may be necessary, especially in highly corrosive environments. Maintenance can extend the life of the grate significantly.

Conclusion

In summary, galvanized drainage grates are an integral component of modern drainage systems, offering a combination of durability, safety, and versatility. Their applications across various environments make them a preferred choice for engineers and urban planners alike. Investing in high-quality galvanized grates is not only a smart economic decision but also a commitment to creating safer, more resilient urban landscapes. As cities continue to grow and face the challenges of climate change, the importance of effective drainage solutions like galvanized grates will only become more pronounced.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025