- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Cost Analysis of Galvanized Steel Bar Grating for Industrial Applications

Understanding the Cost of Galvanized Bar Grating

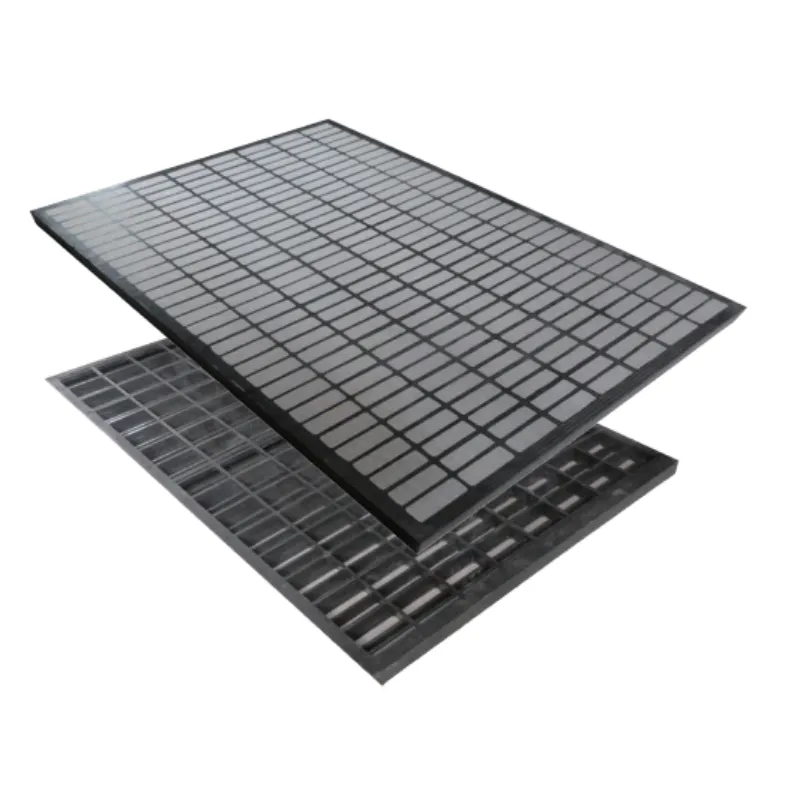

Galvanized bar grating has become a popular choice for a wide range of industrial and commercial applications due to its strength, durability, and non-slip surface. Whether for flooring, walkways, drainage covers, or platforms, galvanized bar grating offers exceptional performance. However, one of the primary considerations for businesses and contractors when selecting this product is cost. In this article, we will explore the factors influencing the cost of galvanized bar grating, typical pricing, and how to optimize your investment.

What is Galvanized Bar Grating?

Galvanized bar grating is made from steel bars that undergo a hot-dip galvanization process to protect them from corrosion and rust. This process involves immersing the steel in molten zinc, resulting in a strong, long-lasting finish. The bars are typically arranged in a grid pattern, allowing for high strength-to-weight ratios while providing excellent drainage and ventilation capabilities.

Factors Influencing Cost

1. Material Type and Quality The cost of galvanized bar grating is heavily influenced by the type and quality of steel used. Higher-grade materials will typically result in a higher price but will also offer enhanced durability and resistance to wear and tear.

2. Thickness and Size The thickness of the bars used and the overall size of the grating can significantly impact its price. Thicker bars and larger panels require more material, leading to increased costs. For heavy-duty applications that demand greater load-bearing capabilities, investing in thicker, more robust grating is crucial.

3. Manufacturing Process The method used to manufacture the bar grating can affect costs. Custom fabrication, for instance, is more expensive than standard products because it involves additional labor and specialized machinery. Pre-made grating panels tend to be more economical, but they may not meet specific project requirements.

4. Surface Treatment While galvanized coating is already a protective measure, additional treatments such as anti-slip coatings can raise the cost. These treatments further enhance the safety and longevity of the grating but must be factored into the overall budget.

galvanized bar grating cost

5. Market Conditions Like any other commodity, the price of steel can fluctuate based on market conditions, including supply and demand, tariffs, and global economic factors. It's essential to stay informed about these trends as they can influence project costs significantly.

6. Shipping and Handling Delivery costs also play a role in the overall price of galvanized bar grating. Larger orders may qualify for bulk shipping discounts, while remote locations might incur additional handling fees. Always consider shipping when budgeting for your purchase.

Typical Pricing

The cost of galvanized bar grating varies widely depending on the factors mentioned above. On average, prices can range from $10 to $30 per square foot for standard-sized panels. Custom sizes and special treatments can push costs well above this average. It's advisable to obtain multiple quotes from suppliers to ensure competitive pricing, especially for large projects.

Optimizing Your Investment

To make the most of your investment in galvanized bar grating, consider the following tips

- Buy in Bulk If your project requires a significant amount of material, purchasing in bulk can lead to substantial savings. - Assess Long-Term Needs While it may be tempting to choose the cheapest option, investing in higher-quality grating can save money in the long run by reducing maintenance and replacement costs. - Consult with Experts Work with suppliers and engineers who can help you select the best products for your specific needs, ensuring durability and functionality. - Plan for Future Use If you're working on multiple projects, consider future needs when buying your galvanized bar grating. This approach allows for greater efficiency in both cost and supply management.

In conclusion, understanding the various factors influencing the cost of galvanized bar grating helps buyers make informed decisions. By considering material quality, manufacturing processes, and market conditions, businesses can optimize their investments while ensuring their projects meet safety and structural requirements.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025