- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

galvanized bar grating cost

Understanding the Costs of Galvanized Bar Grating

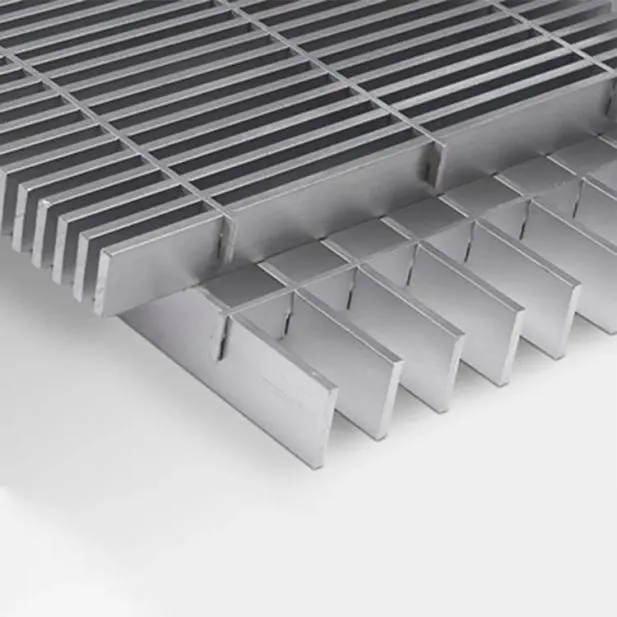

Galvanized bar grating is a popular choice in construction and industrial applications, known for its strength, durability, and resistance to corrosion. However, understanding the cost associated with galvanized bar grating is essential for making informed decisions, whether you are working on a construction project or considering it for safety applications. This article delves into the factors that influence the cost of galvanized bar grating and provides insights into budgeting for your needs.

Factors Influencing Cost

1. Material and Manufacturing Process The primary cost component of galvanized bar grating is the raw materials used, which typically include steel or aluminum. Galvanization, the process of coating steel with zinc to prevent rusting, adds another layer of expense. The manufacturing process also affects costs; custom or specially designed grating may be more expensive due to additional fabrication.

2. Type of Grating There are several types of grating, including welded, press-locked, and swage-locked, each with different production methods and cost implications. Welded grating tends to be more robust and therefore might be priced higher than alternatives. Additionally, the spacing and dimensions of the bars can influence the cost. Closer spacing may require more material and subsequently increase the overall price.

3. Size and Customization Standard sizes of galvanized bar grating are generally cheaper than custom sizes. If your project requires grating in non-standard dimensions, be prepared to pay a premium for customization. Furthermore, specialized coatings or finishes can also increase costs.

4. Market Conditions The price of raw materials fluctuates considerably based on market conditions, including supply chain issues and demand dynamics. Economic factors can lead to increases in the prices of steel and zinc, which will directly affect the overall cost of galvanized bar grating. Keeping an eye on these trends can help you anticipate price changes and make timely purchasing decisions.

galvanized bar grating cost

5. Shipping and Handling Transport costs are often overlooked when budgeting for galvanized bar grating. If your project is in a remote location, the shipping fees can add significantly to the overall cost. Furthermore, large orders may occupy substantial space and require special handling, driving up expenses.

6. Installation Costs While not directly tied to the price of the grating itself, installation is an important consideration. The complexity of installation can vary widely based on your application and the type of grating chosen. Hiring labor to install the grating and the potential need for support frames or other materials should also be factored into the total budget.

Cost Estimates

On average, the cost of galvanized bar grating can range from $5 to $15 per square foot, depending on the factors outlined above. For simpler projects or standard sizes, costs may be on the lower end of the spectrum, whereas custom solutions and larger dimensions can escalate costs significantly.

Conclusion

Galvanized bar grating offers a durable solution for various applications, but it is essential to consider all contributing factors when budgeting for such a project. By understanding the material costs, type selection, size specifications, market dynamics, transportation fees, and installation requirements, you can make more informed decisions. Conduct thorough research and gather quotes from multiple suppliers to ensure you get the best value for your investment. By doing so, you’ll be better positioned to manage your budget effectively while achieving the quality and performance needed for your specific application.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025