- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

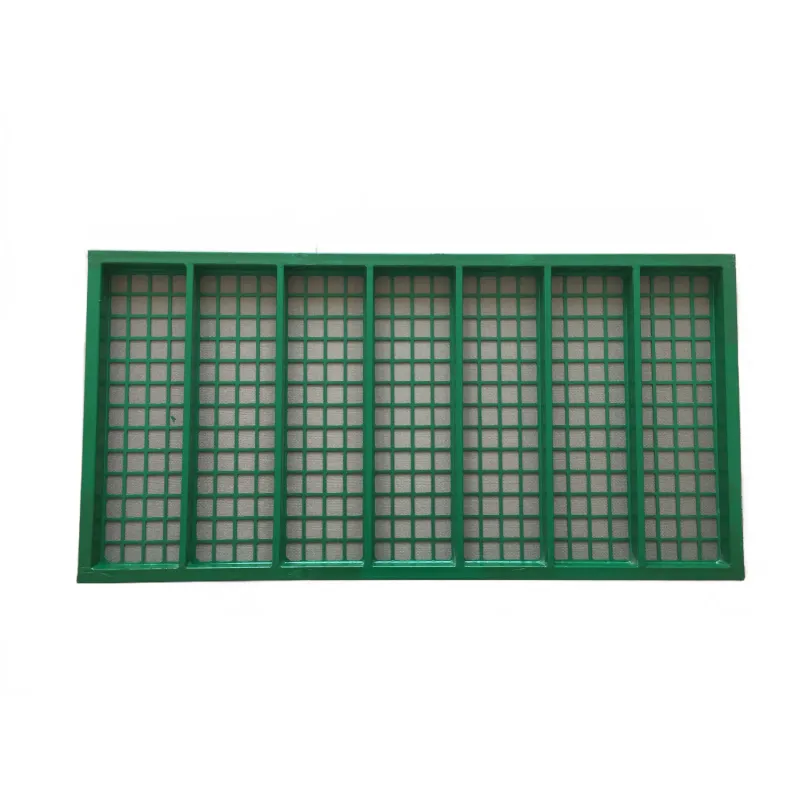

galvanised iron grating

Understanding Galvanised Iron Grating Applications and Benefits

Galvanised iron grating is a pivotal material in various industrial and commercial applications, primarily due to its strength, durability, and resistance to corrosion. It consists of a grid-like structure made from iron that has undergone galvanization, a process in which a protective zinc coating is applied to prevent rust and extend the lifespan of the metal. This article delves into the characteristics, applications, and advantages of galvanised iron grating.

One of the primary benefits of galvanised iron grating is its exceptional strength-to-weight ratio. It is lightweight yet can withstand significant loads, making it an ideal choice for flooring, walkways, and platforms in industrial settings. This grating can accommodate heavy machinery and foot traffic, providing safety and stability in environments where durability is paramount.

The galvanization process also plays a crucial role in protecting the iron from environmental factors. Exposure to moisture, chemicals, and high temperatures can lead to corrosion, which compromises the structural integrity of metal materials. However, the zinc coating applied during galvanization forms a barrier that effectively prevents such damage. As a result, galvanised iron grating is commonly used in outdoor applications, such as sidewalks, drainage covers, and bridge decks.

galvanised iron grating

In addition to its practical applications, galvanised iron grating is also known for its aesthetic appeal. The grid design allows for proper ventilation and light transmission, making it suitable for decorative applications in shopping centers, parks, and landscape designs. Its versatility means it can be used in both functional and decorative roles, enhancing the beauty and utility of spaces.

The installation of galvanised iron grating is relatively straightforward, which reduces labor costs and time. Sections of grating can be easily cut and fitted to specific dimensions, allowing for custom configurations that meet the unique requirements of various projects. Moreover, this type of grating is available in a multitude of sizes, shapes, and finishes, making it adaptable for diverse applications.

Another notable advantage is its low maintenance requirement. Thanks to the protective zinc coating, galvanised iron grating is resistant to the wear and tear that typically affects uncoated metal products. Regular cleaning is usually sufficient to keep it in good condition, which is appealing for facility managers and owners looking to minimize maintenance costs.

In conclusion, galvanised iron grating stands out as a versatile and reliable choice in numerous sectors, including construction, manufacturing, and landscaping. Its combination of strength, corrosion resistance, aesthetic appeal, ease of installation, and low maintenance makes it a preferred material for architects, engineers, and contractors. As industries continue to evolve and seek durable solutions, the demand for galvanised iron grating is expected to remain strong. Investing in this material not only meets immediate structural and aesthetic needs but also contributes to sustainable practices by reducing the need for frequent replacements and repairs.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025