- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Galvanized Steel Floor Grating Solutions for Enhanced Safety and Durability in Industrial Spaces

The Importance of Galvanized Floor Grating A Comprehensive Overview

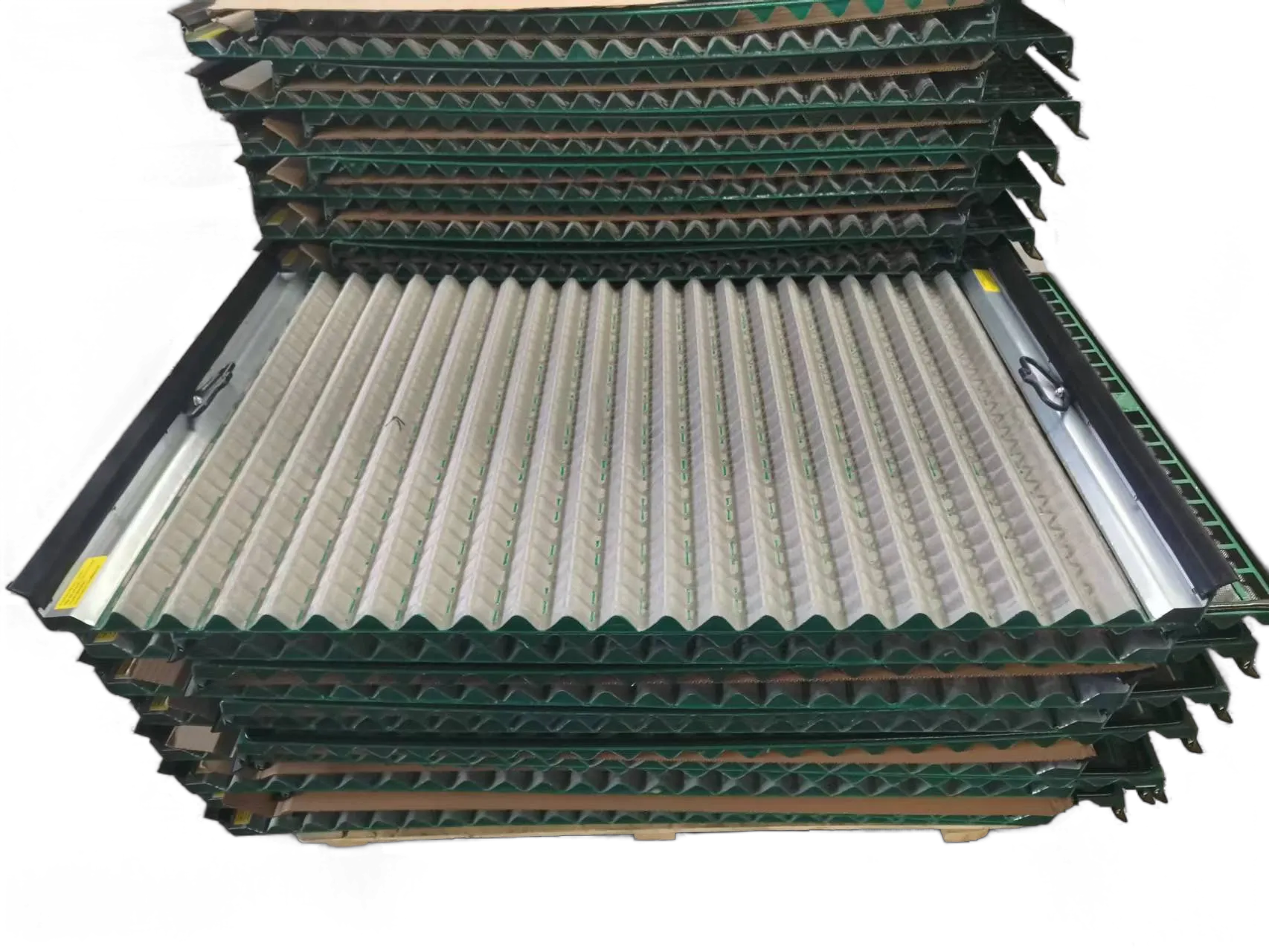

Galvanized floor grating is a versatile and durable solution widely used in various industrial applications. Its unique features, including strength, corrosion resistance, and lightweight design, make it an ideal choice for environments that demand safety and efficiency. In this article, we will explore the advantages, applications, and manufacturing processes of galvanized floor grating, demonstrating its significance in modern construction and industrial settings.

Understanding Galvanized Floor Grating

Galvanized floor grating refers to a type of flooring material that is created by welding together a series of parallel steel bars, which are then coated with a layer of zinc to prevent rust and corrosion. The galvanization process involves submerging the grating in molten zinc, leading to a robust protective layer that extends the lifespan of the material, especially in harsh environments.

Advantages of Galvanized Floor Grating

1. Corrosion Resistance The zinc coating significantly enhances the corrosion resistance of the steel, making galvanized floor grating suitable for outdoor applications or areas exposed to moisture and chemicals. This characteristic reduces maintenance costs and extends the product's service life.

2. Durability and Strength Galvanized floor grating is incredibly strong and can support heavy loads, making it an excellent choice for industrial facilities, warehouses, and factories. Its robust construction ensures safety for personnel and equipment alike.

3. Lightweight Design Compared to traditional concrete flooring, galvanized floor grating is significantly lighter, which simplifies installation and reduces structural load on buildings. This feature is particularly beneficial in retrofitting projects where existing structures need supporting solutions without adding excessive weight.

4. Slip Resistance The design of galvanized floor grating often includes features that enhance traction, minimizing slip hazards in wet or oily environments. This quality is critical in maintaining workplace safety, especially in industries where spills are common.

galvanised floor grating

5. Easy Installation and Modification Galvanized floor grating can be easily cut and adjusted to fit different spaces and configurations. This flexibility simplifies the installation process, enabling faster project completion and reduced labor costs.

Applications of Galvanized Floor Grating

Galvanized floor grating is utilized in a myriad of applications across multiple sectors. Some common uses include

- Industrial Facilities Factories and manufacturing plants often require robust flooring solutions that can withstand heavy machinery and constant foot traffic. Galvanized floor grating provides a durable surface that meets these demands.

- Commercial Spaces Retail outlets, shopping malls, and warehouses benefit from the aesthetic appeal of galvanized grating, which can be combined with other flooring types for a stylish yet functional surface.

- Transportation Areas Airports, train stations, and bus depots often use galvanized grating for walkways, platforms, and vehicular access areas, ensuring safety and reliability for travelers and staff.

- Wastewater Treatment Plants Given their exposure to water and chemicals, wastewater facilities often incorporate galvanized floor grating, which can withstand the harsh conditions related to waste processing.

Conclusion

In conclusion, galvanized floor grating is an indispensable component in various industrial and commercial applications. Its exceptional properties—such as corrosion resistance, strength, lightweight design, and slip resistance—make it a preferred choice among architects, engineers, and construction professionals. As industries continue to evolve and require solutions that meet higher standards of safety and durability, galvanized floor grating will remain a pivotal material, ensuring both structural integrity and workplace safety. Its adaptability to various environments cements its position as a vital asset in modern construction and facility management.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025