- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

From Design to Installation: A Guide to Riveted Grating

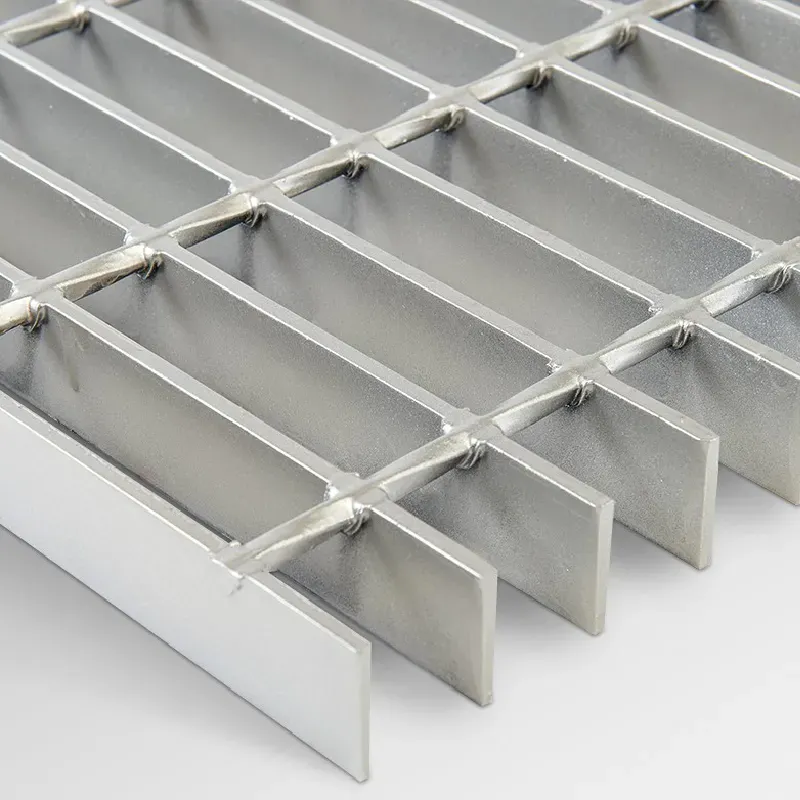

Riveted grating has long been recognized as a durable and versatile solution for industrial and commercial applications. From the initial stages of riveted bar grating production to its seamless installation, understanding the intricacies of this material ensures optimal performance in various settings. With options such as stainless steel floor grating, expanded metal steel grating, and heavy duty mild steel grating, the process from design to application highlights the importance of choosing the right material and configuration for each project.

Stainless Steel Floor Grating: A Premium Choice for Durability and Corrosion Resistance

When selecting materials for environments prone to moisture or chemical exposure, stainless steel floor grating emerges as a reliable option. This material is known for its excellent corrosion resistance and strength, making it ideal for industries like food processing, pharmaceuticals, and marine applications. The production process involves precision engineering to create a surface that balances load capacity with slip resistance. Integrating riveted bar grating into stainless steel designs enhances durability, ensuring the product can withstand heavy loads without compromising safety. This grating type also provides a polished finish that combines functionality with a sleek aesthetic, offering both practical and visual benefits.

Expanded Metal Steel Grating: Lightweight Versatility for Unique Applications

Expanded metal steel grating serves as a versatile solution for projects requiring lightweight yet strong materials. Created through a process of stretching and cutting a metal sheet, this grating offers an open design that supports ventilation and drainage. It is commonly used in walkways, mezzanines, and protective screens where airflow and visibility are essential. Combining expanded metal with heavy duty steel grating structures creates hybrid solutions tailored to specific requirements, such as accommodating increased loads or resisting wear in high-traffic areas. This adaptability underscores the importance of selecting the right grating configuration to align with the unique demands of each project.

Heavy Duty Mild Steel Grating: Strength and Affordability for Industrial Use

For cost-effective solutions in demanding environments, heavy duty mild steel grating offers an ideal balance of strength and affordability. Mild steel's properties make it an excellent choice for industrial platforms, stair treads, and drainage covers. Enhanced through galvanization or protective coatings, this material can withstand harsh conditions while maintaining structural integrity. Pairing riveted bar grating with mild steel configurations further strengthens its load-bearing capacity, ensuring durability in applications requiring robust performance. Its straightforward installation process also makes it a practical choice for projects with tight timelines or budget constraints.

Heavy Duty Steel Grating: Engineered for Maximum Load Capacity

In heavy industrial settings, heavy duty steel grating plays a crucial role in supporting significant loads and resisting wear. This type of grating is designed to handle the demands of high-impact applications, such as heavy machinery platforms, vehicle access ramps, and industrial flooring. The incorporation of riveted bar grating into heavy-duty designs enhances its stability, ensuring consistent performance even under dynamic stress. Additionally, heavy-duty steel grating can be customized with serrated surfaces to improve slip resistance, making it a safe and reliable option for challenging environments. This flexibility in design ensures that the material meets specific safety and operational requirements.

Riveted Bar Grating: Precision Design for Long-Term Performance

The production of riveted bar grating involves a meticulous process that ensures structural integrity and reliability. Riveting combines load-bearing bars with cross members through mechanical pressure, creating a durable and stable platform. This design enhances the grating's ability to distribute loads evenly while minimizing deflection. Applications of riveted grating range from industrial walkways to architectural installations, where its strength and visual appeal are equally valued. Whether used alongside stainless steel floor grating for corrosion resistance or integrated with expanded metal steel grating for ventilation, riveted designs offer unmatched versatility. This adaptability makes it a cornerstone of modern grating solutions.

From initial material selection to precise installation, the journey of riveted bar grating demonstrates its critical role in creating durable, safe, and efficient solutions for diverse environments. This step-by-step approach underscores the importance of thoughtful design and careful application in maximizing the benefits of riveted grating systems.

-

Unlocking Efficiency with Premium Shaker ScreensNewsAug.05,2025

-

Safety and Style with Metal Grate WalkwayNewsAug.05,2025

-

Optimize Operations with Shaker Screen SolutionsNewsAug.05,2025

-

Enhance Your Space with Steel GratingNewsAug.05,2025

-

Durability with Concrete Weight Coating MeshNewsAug.05,2025

-

Discover the Power of Perimeter Safety NetNewsAug.05,2025