- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

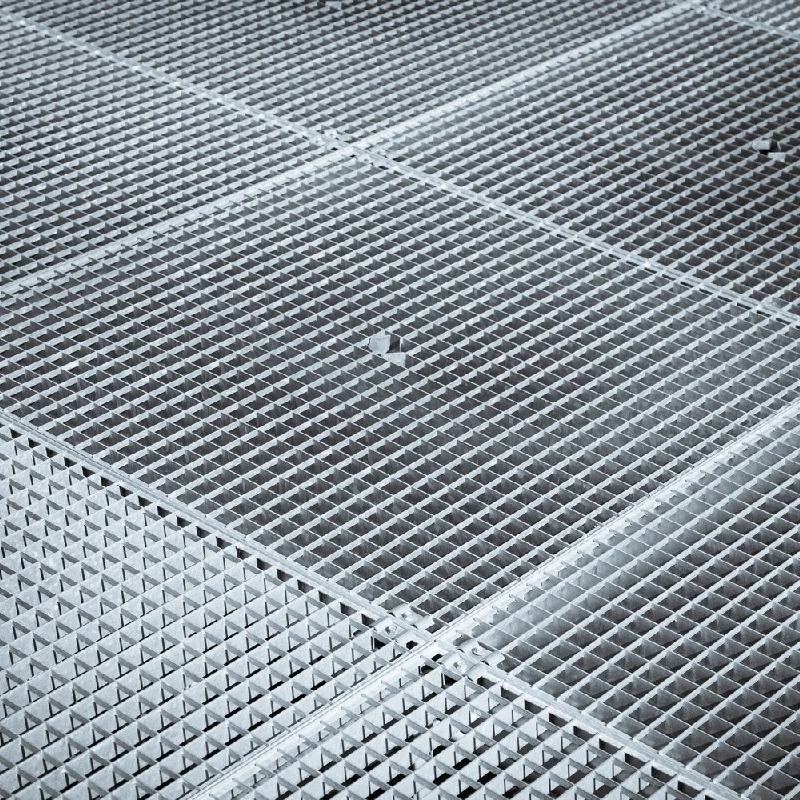

flowforge grating

Understanding Flowforge Grating An In-Depth Exploration

Flowforge grating, an innovative concept in the realm of optics, has been making waves in various scientific and engineering applications. Gratings, in general, are optical components that disperse light into its constituent wavelengths, making them essential in spectroscopy, telecommunications, and laser applications. Flowforge grating introduces a novel approach to traditional grating designs by integrating advanced manufacturing techniques and material science.

At its core, flowforge grating leverages a unique patterning process to create finely controlled surface structures. The term flowforge suggests a dynamic and adaptable methodology that can be applied to a wide range of materials. This ability to manipulate the surface at microscopic levels enables the fabrication of gratings that can achieve exceptional resolution and efficiency. The underlying technology often incorporates advanced computational algorithms and precision manufacturing tools.

One of the most significant advantages of flowforge grating is its versatility. Traditional gratings are often limited by their physical properties and reliance on specific materials. In contrast, flowforge allows researchers and engineers to use a broader range of substrates, including polymers, metals, and even glass. This versatility opens up new opportunities for custom applications across various industries, from telecommunications, where high-speed data transmission is critical, to biological sensing, where precise wavelength discrimination can lead to significant advancements in medical diagnostics.

Moreover, flowforge grating enhances the performance of optical systems by improving efficiency and reducing signal loss. Traditional surface gratings can suffer from issues such as scattering and reflection losses, which diminish the quality of the transmitted signal. Flowforge technology, with its meticulously engineered surfaces, addresses these concerns by maximizing transmission efficiency. This improvement is particularly beneficial in applications like fiber optics, where maintaining signal integrity over long distances is essential.

flowforge grating

The process involves sophisticated engineering techniques, often combining computer-aided design (CAD) with advanced fabrication methods such as laser micromachining or photolithography. The result is a grating that not only meets the specifications required for high-performance applications but also offers a degree of customization that was previously unattainable. Engineers can fine-tune the groove spacing, depth, and profile to optimize performance for specific wavelengths or applications, providing a tailored solution that can adapt to various scientific needs.

Additionally, the growing demand for miniaturization in technology drives the need for more compact and efficient optical components. Flowforge grating is ideally suited for this trend. Its ability to produce high-resolution patterns in small form factors makes it a prime candidate for integration into microelectromechanical systems (MEMS) and other compact optical circuits. As the industry moves towards smaller devices with enhanced capabilities, technologies like flowforge grating will be at the forefront of this evolution.

Furthermore, the environmental impact of manufacturing processes is an increasingly important consideration in modern engineering. The flowforge methodology, with its potential for waste reduction and resource efficiency, aligns well with sustainable practices. By enabling the production of highly optimized components with less material waste, it contributes to the growing emphasis on green technology in the optics industry.

In conclusion, flowforge grating represents a significant advancement in optical technology, combining innovative design, material versatility, and manufacturing efficiency. Its applications are vast, spanning telecommunications, medical diagnostics, and beyond. As researchers continue to explore its potential and refine its capabilities, flowforge grating is poised to redefine standards in optical performance and customization. The blending of advanced engineering with practical applications not only enhances our understanding of light manipulation but also paves the way for new technologies that could transform industries in the years to come. Ultimately, the impact of flowforge grating underscores the importance of continued innovation in optics and its crucial role in shaping the future of technology.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025