- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

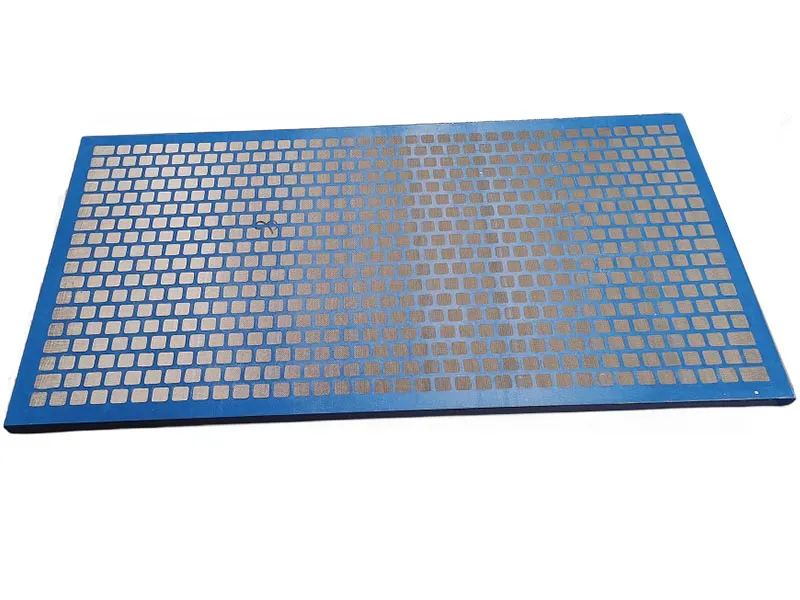

flowforge grating

Understanding Flowforge Grating An Innovative Approach in Optics

Flowforge gratings represent a significant advancement in optical technology, particularly in the fields of telecommunications, spectroscopy, and imaging systems. This article delves into the fundamentals of flowforge grating technology, its applications, physics behind its operation, manufacturing processes, and what makes it a preferred choice in many optical systems today.

What is Flowforge Grating?

Flowforge grating is a type of diffractive optical element (DOE) characterized by its unique ability to manipulate light through a series of structured patterns or grooves. These gratings can be produced with high precision and are designed to reflect or transmit light at specific angles, thereby controlling the wavefront of the light passing through it. This precise control over light propagation makes flowforge gratings vital in various optical applications.

The Physics Behind Flowforge Grating

The operation of flowforge gratings is based on the principles of diffraction. When light encounters the grooves or structures of the grating, it is diffracted into several orders, each corresponding to a specific angle determined by the grating's spacing. The diffraction pattern is influenced by several factors, including the wavelength of the light, the angle of incidence, and the physical dimensions of the grooves. The ability to manipulate these variables allows designers to customize gratings for specific applications, enhancing their performance in optical systems.

Manufacturing Process

Creating flowforge gratings involves advanced fabrication techniques. One of the prevalent methods is photolithography, where a light-sensitive material is applied to a substrate and exposed to patterns of light that define the grating structure. After exposure, the material is developed to create the desired groove pattern. Other methods include etching and laser ablation, which are particularly useful for producing intricate designs needed for specialized applications.

The precision of the manufacturing process is crucial. Even minor variations in the groove width or depth can significantly affect the grating’s performance and efficiency. As such, quality control measures are essential throughout the production process to ensure that every grating meets strict specifications.

flowforge grating

Applications of Flowforge Gratings

Flowforge gratings find extensive use across various industries. In telecommunications, they are employed in wavelength division multiplexing (WDM) systems to manage multiple channels of data transmission over fiber optic cables, thereby increasing data throughput without requiring additional infrastructure.

In spectroscopy, flowforge gratings are integral to optical spectrometers that analyze the light spectra from various materials. They help identify chemical compositions and molecular structures by dispersing light into its constituent wavelengths.

Additionally, flowforge gratings are used in imaging systems, including cameras and projectors, to enhance image quality and improve focus and clarity. They help correct optical aberrations and manage light distribution, ensuring that optical systems perform at their best.

Advantages Over Traditional Gratings

One of the significant benefits of flowforge gratings over traditional reflective or transmissive gratings is their versatility. Their customizable designs allow engineers to optimize them for specific tasks — whether for minimizing losses, maximizing throughput, or achieving specific diffraction angles.

Moreover, flowforge gratings can often be produced at a lower cost than their traditional counterparts due to advancements in fabrication technology. This affordability, coupled with high performance, makes them an attractive option for both research and commercial applications.

Conclusion

In conclusion, flowforge gratings stand at the forefront of optical technology, offering enhanced capabilities for controlling light in various applications. Their intricate design, coupled with precise manufacturing techniques, enables a level of performance that is essential for the demands of modern optical systems. As industries continue to evolve and the need for sophisticated optical solutions grows, flowforge grating technology presents promising opportunities for innovation and expansion, paving the way for future advancements in the field of optics. Understanding the principles and benefits of flowforge gratings not only highlights their importance but also sets the stage for further exploration of this transformative technology.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025