- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

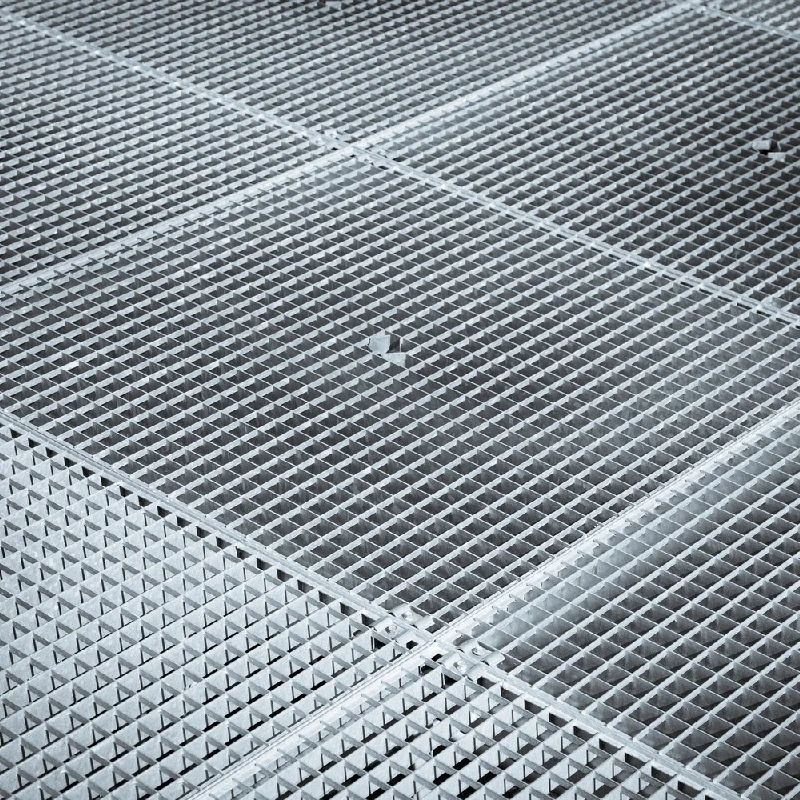

floor grating price

Understanding Floor Grating Prices A Comprehensive Overview

Floor grating serves as a crucial component in various industrial and commercial applications. Its primary function is to provide a strong, safe, and durable surface for foot traffic, equipment, and machinery. However, as with any product, understanding the factors that influence floor grating prices is essential for both purchasing decisions and project budgeting.

Types of Floor Grating

Floor grating comes in several materials and designs, each affecting the cost. Common types include steel, aluminum, and fiberglass reinforced plastic (FRP). Steel grates offer strength and longevity, making them suitable for heavy-duty applications, while aluminum options are lighter and resistant to corrosion, suitable for damp environments. FRP grating, on the other hand, boasts advantages in chemical resistance and non-conductivity, making it ideal for specialized industrial applications.

The choice of material can reflect significantly on the price. For example, while steel grating may be less expensive initially, its installation might require more robust support structures, adding to overall costs. Conversely, FRP, though typically pricier, can lead to savings long-term due to lower maintenance needs.

Factors Influencing Prices

1. Material Quality The grade and quality of the materials used in manufacturing the grating have a direct impact on cost. High-quality materials generally yield a more durable product but will also carry a higher price tag.

2. Load Capacity Floor grating is designed to withstand specific loads based on its intended use. Gratings designed for heavy loads or high traffic areas tend to be more expensive due to the additional materials and engineering required.

floor grating price

3. Size and Configuration Custom sizes and shapes can influence pricing. Standard sizes are usually more affordable as they are mass-produced, while custom or irregular sizes may incur additional manufacturing costs.

4. Surface Treatments Some floor gratings obtain additional treatments such as powder coating or galvanization, which enhance their corrosion resistance or aesthetic appeal. These treatments can add to the final price.

5. Installation Costs The complexity of installation can also affect overall expenses. Some types of floor grating are more straightforward to install than others, leading to a variance in labor costs.

6. Market Trends Prices may fluctuate based on market demand and supply chain factors. Events that disrupt material availability can lead to sudden price increases, while greater competition in the market can drive costs down.

Estimating Costs

When considering floor grating, it is advisable to obtain quotes from multiple suppliers, taking into account the previously mentioned variables. A rough estimate for floor grating prices can range from $3 to $10 per square foot, depending on the factors outlined. Additionally, don’t forget to factor in installation costs, which can vary widely based on location and job complexity.

Conclusion

In conclusion, while floor grating prices can vary significantly based on a multitude of factors, being informed can help in making astute purchasing decisions. Understanding the different types of grating and their associated costs allows buyers to select the best material for their particular needs without overspending. Whether you are working on a large industrial project, a commercial building, or simply need grating for residential use, taking the time to research and compare options will ensure that you achieve both quality and value in your floor grating investment.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025