- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

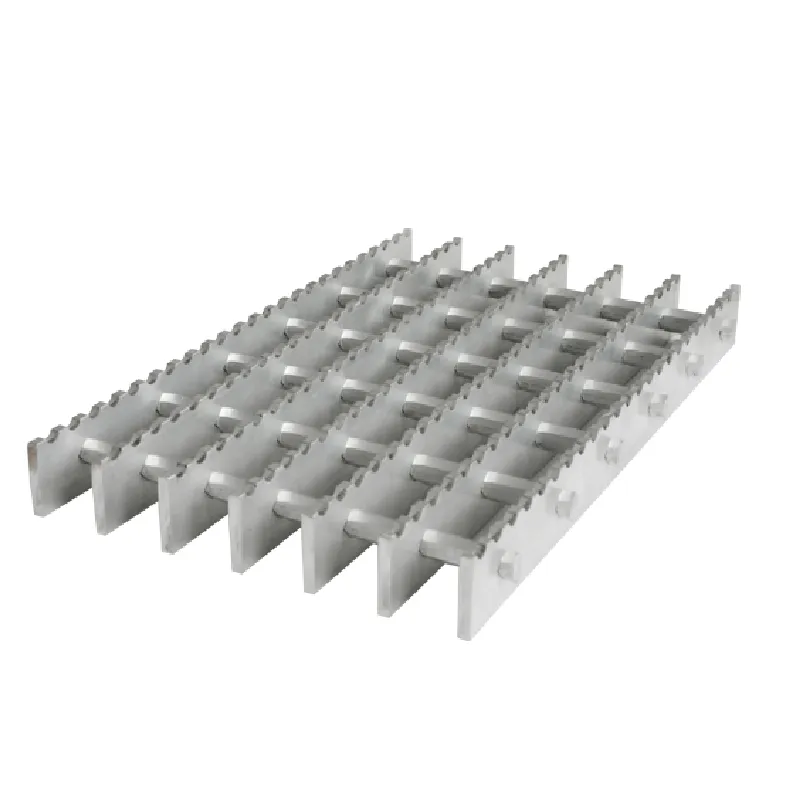

Affordable Options for Floor Grating Pricing and Selection Guide

Understanding Floor Grating Prices What to Consider

When it comes to industrial and commercial flooring solutions, floor grating plays a crucial role in providing safety, durability, and functionality. From walkways to drainage systems, floor grating can be found in a variety of applications. However, one of the most frequently asked questions by potential buyers is What factors influence floor grating prices? This article explores the key components that affect the cost of floor grating, helping you make informed decisions for your projects.

Types of Floor Grating

Floor grating comes in several types, each with its unique characteristics, materials, and uses. The main categories include

1. Metal Grating Often made from steel, aluminum, or stainless steel, these gratings are highly durable and suitable for heavy loads, making them popular in industrial settings. 2. Fiberglass Re-enforced Plastic (FRP) Grating This type is lightweight, corrosion-resistant, and offers excellent chemical resistance, making it ideal for environments exposed to harsh substances.

3. Wood Grating While less common than metal or FRP, wood grating is sometimes used for aesthetic applications or temporary setups.

Each type of grating will have different price points based on material costs and manufacturing processes.

Material Costs

The price of floor grating is significantly influenced by the materials used in its construction.

- Metal Prices Fluctuations in the prices of steel, aluminum, and other metals can cause variations in grating costs. For instance, a rise in the steel market typically leads to increased prices for steel grating.

- Composite Materials FRP grating tends to be more cost-effective in environments where metal would corrode or rust, thus reducing long-term maintenance costs. However, initial production costs can be higher than those for metal options.

floor grating price

Manufacturing Processes

The manufacturing process also affects the price of floor grating. Custom gratings, which are designed to meet specific dimensions or load-bearing requirements, will typically cost more than standard options. Additionally, processes like welding, cutting, and finishing add to the overall expense.

Load-Bearing Capacity

Load-bearing capacity is another factor influencing costs. Floor gratings are designed to handle different weights, and those with higher load capacities tend to be more expensive due to additional materials and reinforcement processes.

Surface Finish and Safety Features

Safety is a priority, especially in industrial environments. Gratings can be treated with anti-slip finishes, coatings, or painted for corrosion resistance. These additional safety features contribute to the overall cost, as they require extra materials and labor for installation.

Quantity and Customization

The quantities being purchased also play a significant role in price determination. Bulk orders typically qualify for discounts, lowering the per-unit cost. Conversely, purchasing small quantities may not be as economical.

Customization options, such as specific sizes, edge treatments, or colors, can also increase the price. Customers should weigh the benefits of customized gratings against their budget constraints.

Conclusion

In conclusion, determining the price of floor grating is a multifaceted process influenced by type, material costs, manufacturing processes, load-bearing capacity, and customization options. When considering floor grating for your projects, it’s crucial to assess not only the upfront costs but also the long-term value and durability of the chosen solution. By understanding these factors, you can choose the right floor grating to meet your needs while staying within your budget. Whether you are outfitting a factory, a warehouse, or a recreational space, doing your homework on floor grating prices can lead to smarter purchasing decisions and better overall project outcomes.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025