- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

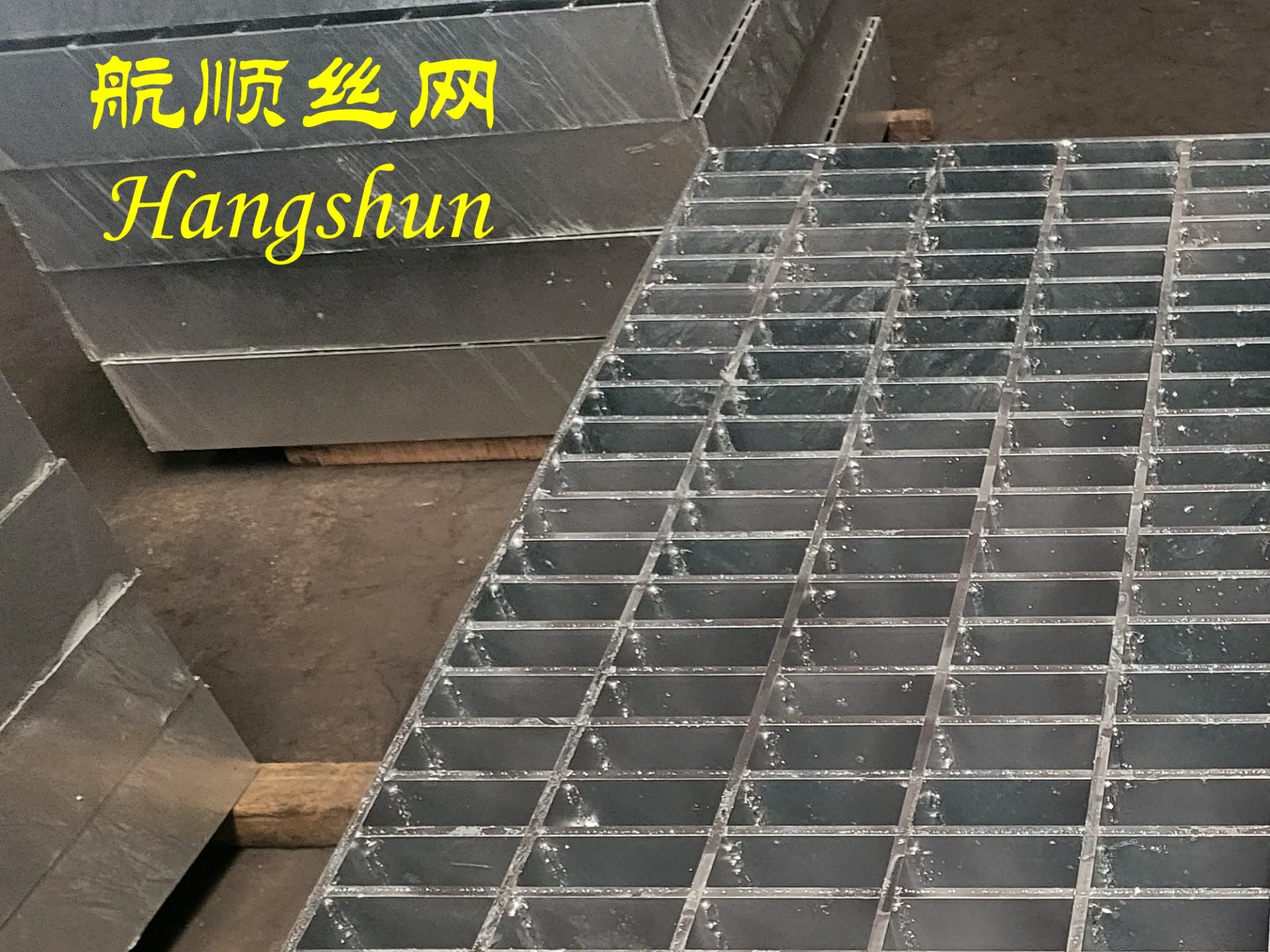

floor forge walkway steel galvanised grating

The Importance of Galvanised Steel Grating in Floor, Forge, and Walkway Applications

In the realms of construction and industrial design, floor, forge, and walkway systems are integral components requiring durable and reliable materials. One material that has risen in popularity due to its remarkable characteristics is galvanised steel grating. This article explores the advantages of using galvanised steel grating in various applications, particularly in flooring, forging areas, and walkways.

Understanding Galvanised Steel Grating

Galvanised steel grating is created through a process known as galvanisation, where steel is coated with a layer of zinc to enhance its resistance to corrosion. This protective layer is crucial for extending the lifespan of steel products, particularly in environments that are exposed to moisture, chemicals, or heavy foot traffic. The combination of steel's strength with zinc's corrosion-resistance creates an ideal solution for demanding applications.

Advantages in Flooring

When it comes to flooring, particularly in industrial settings, safety and durability are paramount. Galvanised steel grating provides excellent slip resistance, which is vital in preventing accidents in busy areas where workers and machinery operate simultaneously. Its open design allows for efficient drainage and airflow, reducing the accumulation of water and debris, which can lead to hazardous conditions.

Moreover, the strength of galvanised steel means it can support heavy loads, making it suitable for factories, warehouses, and even outdoor platforms. The longevity of galvanised steel grating also translates to lower maintenance costs over time, as its resistance to rust and degradation minimizes the need for frequent replacements.

Applications in Forge Areas

floor forge walkway steel galvanised grating

Forge areas are particularly hostile environments where heat, sparks, and heavy loads are common. Here, the use of galvanised steel grating becomes even more critical. The high-temperature resistance of steel ensures that it will not warp or bend under extreme conditions. Additionally, the galvanisation process provides an extra layer of protection against the oxidising effects of heat and moisture, which are prevalent in forges.

Furthermore, the open design of the grating allows for efficient removal of debris and waste materials, keeping the working area safe and clear. For forge workers, having a stable, slip-resistant surface underfoot is essential, as it not only aids in their mobility but also contributes to overall workplace safety.

Benefits for Walkways

Galvanised steel grating is an excellent choice for walkways, both indoors and outdoors. Its lightweight yet robust construction can handle substantial amounts of foot traffic without compromising structural integrity. In outdoor environments, the galvanised coating protects against harsh weather conditions, including rain, snow, and even UV radiation.

The aesthetic versatility of galvanised steel grating can also enhance the visual appeal of walkways. Available in a variety of designs and finishes, it can fit seamlessly into various architectural styles. Additionally, its transparency fosters a minimalist appearance, allowing for an unobstructed view of the surroundings while providing necessary safety features.

Conclusion

In conclusion, galvanised steel grating is a highly effective material for use in floor, forge, and walkway applications. Its durability, corrosion resistance, slip safety, and easy maintenance make it an ideal choice for industrial, commercial, and outdoor settings. As industries continue to prioritise safety and longevity in their materials, the preference for galvanised steel grating is likely to grow. Whether for constructing safe walkways, durable flooring, or robust surfaces in forge areas, galvanised steel grating stands out as an exemplary solution, underscoring the blend of strength and practicality in modern construction practices.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025