- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

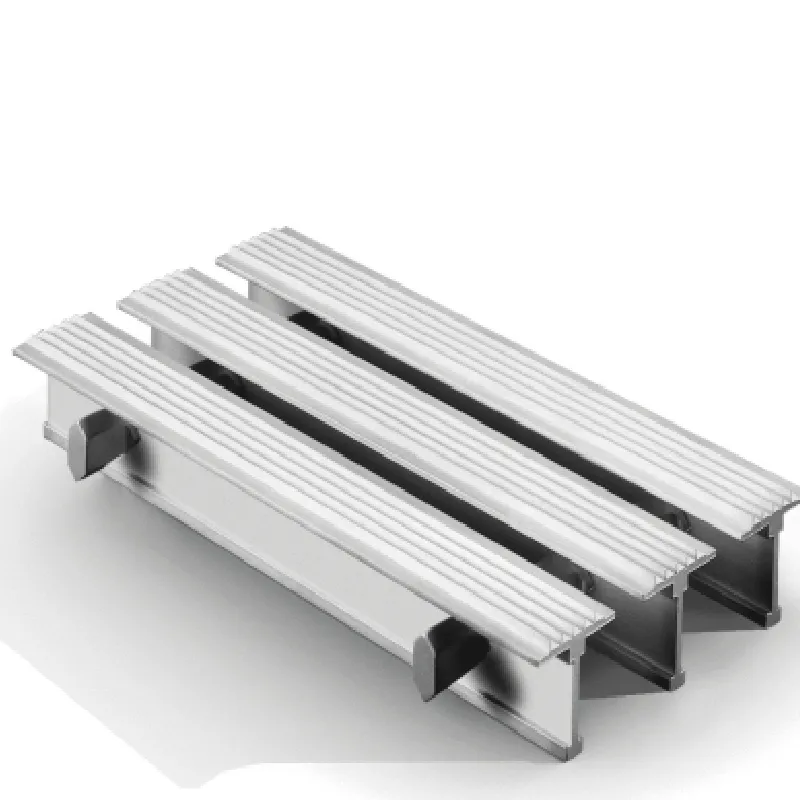

Durable Hot Dip Galvanized Steel Grating for Enhanced Corrosion Resistance in Industrial Applications

Hot Dip Galvanized Steel Grating A Comprehensive Overview

Hot dip galvanized steel grating is a vital component in various industrial and commercial applications. This durable and corrosion-resistant material is primarily used for walkways, platforms, drainage covers, and other structures that require strong support and safety for pedestrian traffic or heavy loads. Trustworthiness in design and construction is crucial, and hot dip galvanized steel grating delivers on both fronts.

The process of hot dip galvanization involves submerging steel grating or other steel components in a bath of molten zinc. This procedure creates a robust coating that not only protects the steel from environmental factors but also enhances its longevity. The resulting galvanized layer acts as a barrier against rust and corrosion, which is particularly important in harsh conditions, such as exposure to chemicals, moisture, or extreme weather.

One of the primary advantages of using hot dip galvanized steel grating is its exceptional durability. Unlike untreated steel, which may begin to corrode after just a few months of exposure to the elements, galvanized steel can provide decades of service life. This makes it a cost-effective choice for projects that demand long-lasting materials and reduces the need for frequent maintenance or replacement.

In addition to its durability, hot dip galvanized steel grating is admired for its design versatility. It can be manufactured in various sizes and configurations, making it suitable for a wide range of applications. Common uses include industrial flooring, stair treads, and even as fencing or screening. Furthermore, its open design allows for excellent drainage and ventilation, making it ideal for environments where liquids might accumulate.

hot dip galvanized steel grating

Safety is another critical factor to consider when discussing hot dip galvanized steel grating. The surface of the grating is designed to provide excellent traction, reducing the risk of slips and falls. This makes it a preferred choice for walkways, loading docks, and factory floors, ensuring that workers and pedestrians can navigate these areas with confidence.

Moreover, the light weight of galvanized steel grating compared to solid flooring panels enhances its appeal. Its lighter profile not only eases installation but can also reduce the load on supporting structures, offering both economic and structural advantages.

Environmental sustainability is becoming an increasingly important consideration in construction and manufacturing. Hot dip galvanized steel is 100% recyclable, which contributes to sustainable building practices. When the need arises to replace old grating, the material can be processed and repurposed, thereby minimizing waste and reducing the environmental footprint of construction projects.

In conclusion, hot dip galvanized steel grating is a durable, versatile, and cost-effective solution for a wide range of industrial and commercial applications. Its longevity, safety features, and environmental benefits make it a smart choice for designers and engineers who seek reliable materials for their projects. As industries continue to evolve and prioritize safety and sustainability, hot dip galvanized steel grating stands out as a trusted option, delivering unmatched performance and value for years to come. Whether it's for constructing walkways in a busy factory or creating safe platforms in a chemical processing facility, hot dip galvanized steel grating is an essential element that combines functionality with longevity, ensuring that it meets the demands of today's fast-paced industrial environment.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025