- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

derrick pyramid screens

Exploring the Derrick Pyramid Screens Efficiency in Separation Technology

In the realm of mineral processing, efficient separation techniques are crucial for optimizing resources and enhancing production rates. Among the various technologies available, Derrick Pyramid Screens have emerged as a leading solution. Designed to improve the classification process in industries such as mining, aggregates, and recycling, these screens offer distinct advantages that set them apart from traditional screening methods.

The Design and Functionality of Derrick Pyramid Screens

Derrick Pyramid Screens feature a unique three-dimensional pyramid shape that enables a higher capacity for material processing. The innovative design dramatically increases the effective screen surface area compared to conventional flat screens. This allows for more efficient screening of finer particles, ultimately enhancing the overall throughput of operations.

Each screen is equipped with multiple layers of mesh that can be tailored to specific particle sizes. By utilizing various mesh sizes, Derrick Pyramid Screens can effectively separate materials based on their characteristics, ensuring that the end-product is of the highest quality. The pyramid structure allows for greater stratification of the material as it moves across the screen, leading to enhanced separation efficiency.

Advantages Over Traditional Screening Methods

One of the significant advantages of Derrick Pyramid Screens is their ability to minimize blinding and pegging, a common challenge in traditional screening systems. Blinding occurs when particles accumulate on the screen surface, obstructing the flow of finer materials. Derrick's unique design and vibration system reduce the likelihood of this issue, thereby maintaining continuous productivity.

Additionally, these screens are engineered for durability and longevity. Constructed from high-quality materials, they are robust enough to withstand harsh operational environments. This resilience translates to reduced maintenance costs and downtime, ultimately contributing to a more efficient operation.

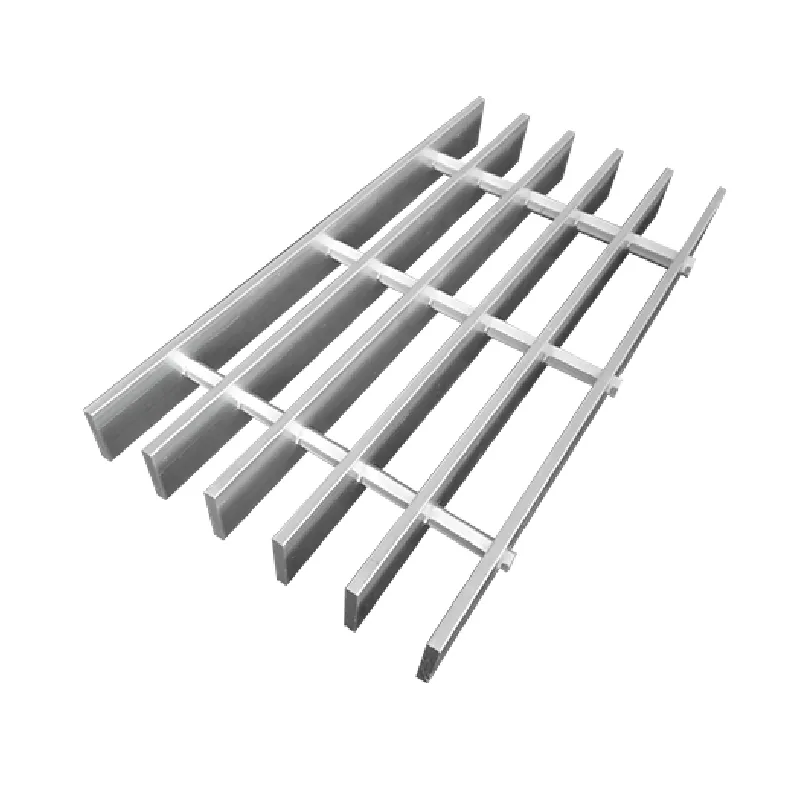

derrick pyramid screens

Applications in Various Industries

Derrick Pyramid Screens are widely utilized across different sectors. In the mining industry, they are instrumental in the separation of minerals, such as coal, gold, and iron ore. The capability to handle a wide range of particle sizes makes these screens versatile for various materials, from fine dust to coarse aggregates.

In the aggregates industry, Derrick Pyramid Screens assist in producing high-quality concrete and asphalt by effectively classifying different size fractions of gravel and sand. Their efficiency in removing undersized materials ensures that only the best particles contribute to the final product.

Furthermore, the recycling industry benefits significantly from Derrick Pyramid Screens. These screens play an essential role in the separation of recyclable materials, such as plastics, metals, and glass, helping to promote sustainability and reduce waste.

Conclusion

The Derrick Pyramid Screens represent a significant advancement in the field of separation technology. Their innovative design, combined with the ability to handle a diverse range of materials, makes them an invaluable asset for various industries. As companies continue to seek ways to improve productivity and efficiency, investing in advanced screening technologies like Derrick Pyramid Screens will undoubtedly prove beneficial. By minimizing operational challenges and maximizing output, businesses can enhance their competitive edge in today's fast-paced market.

In summary, Derrick Pyramid Screens offer not only superior performance and reliability but also contribute to more sustainable practices within the mining, aggregates, and recycling sectors. With ongoing innovations in technology, these screens are poised to remain at the forefront of efficient material separation for years to come.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025