- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

CWC Pipe Coating Solutions for Enhanced Durability and Performance in Industrial Applications

Understanding CWC Pipe Coating Enhancing Durability and Efficiency

CWC (Coal Water Slurry) pipe coating has emerged as a critical technique in various industries, especially where pipes are used to transport coal water slurry mixtures. The unique properties of CWC pipes demand a thorough understanding of the coating processes involved to ensure that these systems remain efficient and durable under challenging conditions.

Importance of Pipe Coating

Pipe coating serves several vital functions. Firstly, it protects pipes from corrosion caused by chemical reactions and environmental factors. Corrosion can lead to leaks and eventually failure of the pipeline, resulting in costly repairs and operational downtime. Secondly, coatings can improve the flow of materials through the pipes by reducing friction, thereby enhancing overall efficiency. Lastly, effective coatings offer thermal insulation, which is particularly useful in maintaining the desired temperature of the transported materials.

Types of Coatings

There are various types of coatings suitable for CWC pipes, each with distinct properties tailored to meet specific needs. The choice of coating largely depends on the nature of the slurry being transported, the environmental conditions, and budget considerations.

1. Epoxy Coatings Known for their excellent adhesion and resistance to chemicals, epoxy coatings are among the most commonly used. They create a tough barrier against corrosion and can withstand high temperature fluctuations, making them ideal for CWC applications.

2. Polyurethane Coatings These coatings are flexible and resistant to impact, providing a high level of durability. They are also UV-resistant, which helps maintain performance when exposed to sunlight, making them suitable for outdoor applications.

3. Polyethylene Coatings This type offers good chemical resistance and is especially effective in preventing abrasion, which is a common issue in CWC systems where solid particles can cause wear over time.

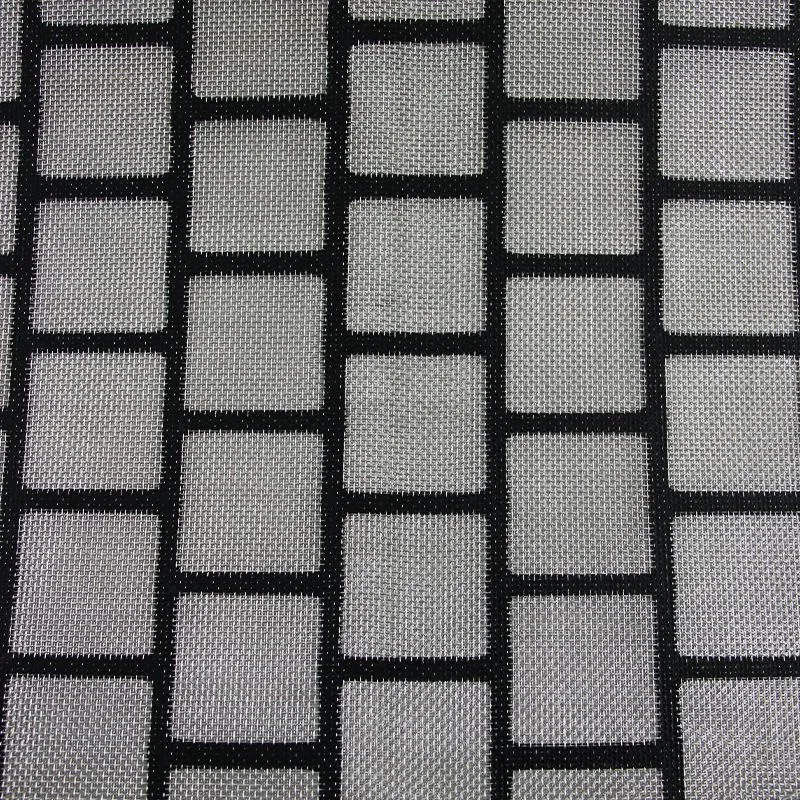

cwc pipe coating

4. Fusion Bonded Epoxy (FBE) A popular choice for steel pipes, FBE coatings are applied in a molten state, allowing for excellent adhesion and corrosion resistance. They are particularly advantageous in severe environmental conditions.

Application Process

The application of CWC pipe coatings is a meticulous process that generally involves several steps to ensure optimal results. Initially, the surface of the pipes must be thoroughly cleaned to remove any contaminants, rust, or prior coatings. This can involve sandblasting or power washing.

Once the surface is prepared, the chosen coating is applied either through spraying, rolling, or a dipping process. It is essential to adhere to the manufacturer’s guidelines regarding thickness and curing times to achieve the desired protective properties. After the application, the coating usually undergoes a curing process, which may involve exposure to heat or specific environmental conditions to ensure proper bonding and durability.

Maintenance and Inspection

Maintaining CWC pipeline coatings is crucial for long-term efficiency. Regular inspections should be scheduled to identify any signs of damage, wear, or corrosion. Advanced techniques such as ultrasonic testing or visual inspections can be utilized to assess the integrity of the coating. If any flaws are discovered, timely repairs can prevent larger issues and extend the life of the pipeline.

Conclusion

CWC pipe coating plays an integral role in the reliability and efficiency of coal-water slurry transportation systems. The right type of coating, combined with a proper application process and regular maintenance, can greatly enhance the performance and lifespan of pipes. As industries continue to embrace advancements in materials and coating technologies, investing in quality pipe coatings will remain a priority for those involved in the transportation of coal-water slurries and other materials. By understanding and implementing effective coating solutions, companies can ensure the successful operation of their pipeline systems, minimizing costs and maximizing productivity.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025