- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

CWC Pipe Coating Solutions for Enhanced Durability and Performance

Understanding CWC Pipe Coating An Essential for Durability and Protection

When it comes to the transportation of fluids and gases in various industrial applications, the integrity and longevity of pipes are paramount. A critical solution that has emerged in this field is CWC pipe coating, a protective layer designed to enhance the performance and lifespan of pipeline systems. In this article, we will delve into what CWC pipe coating is, its benefits, application procedures, and the materials involved.

What is CWC Pipe Coating?

CWC, which stands for Coating With Corrosion, is a specialized coating applied to pipelines to protect them against various forms of corrosion, abrasion, and other environmental factors that can lead to deterioration over time. This type of coating is particularly significant in industries such as oil and gas, water treatment, and chemical processing, where pipes are exposed to harsh conditions.

The CWC method typically involves the application of a polymer-based paint or a fusion-bonded epoxy that forms a durable barrier over the surface of the pipe. This barrier prevents moisture and other corrosive agents from penetrating the metal, thus minimizing the risk of rust and corrosion.

Benefits of CWC Pipe Coating

1. Corrosion Resistance One of the primary benefits of CWC pipe coating is its ability to resist corrosion. By providing a protective layer, the coating effectively extends the life of the pipes, reducing the frequency of repairs and replacements.

2. Enhanced Durability CWC coatings are engineered to withstand extreme temperatures and pressures, making them suitable for a wide range of applications. This durability helps maintain the structural integrity of pipelines even in demanding environments.

3. Cost-Effectiveness While the initial application of CWC pipe coating may involve a certain investment, the long-term savings associated with reduced maintenance, fewer repairs, and prolonged pipe life make it a cost-effective option.

4. Environmental Protection CWC coatings contribute to environmental sustainability by preventing leaks and spills from pipelines, which can lead to soil and water contamination. By ensuring the safe transport of fluids and gases, these coatings help protect ecosystems and communities.

5. Improved Flow Efficiency A smooth, coated pipe surface reduces friction and turbulence, which can enhance the flow efficiency of the transported fluids and gases. This can result in energy savings and improved operational performance.

Application Procedure

The application of CWC pipe coating is a meticulous process that requires careful preparation and execution. Here are the key steps involved

cwc pipe coating

1. Surface Preparation Before applying the coating, the surface of the pipe must be thoroughly cleaned and prepared. This may involve sandblasting, power washing, or chemical cleaning to remove any existing rust, dirt, or contaminants.

2. Coating Application The CWC coating is then applied using various methods, including spray, brush, or dip coating. The choice of application method can depend on the size of the pipe, the coating material, and the specific requirements of the project.

3. Curing After application, the coating must cure to achieve its full protective properties. Curing times can vary based on the specific materials used and environmental conditions.

4. Inspection and Quality Control Once cured, the coated pipes undergo thorough inspections to ensure the coating has adhered properly and no areas are missed. Quality control measures are essential to verify that the coating meets industry standards.

5. Installation Finally, the coated pipes can be installed in their intended location, ready to serve their function while being protected from the elements.

Materials Used in CWC Coating

Several materials can be used for CWC pipe coatings, including

- Epoxy Resins Known for their excellent adhesion and resistance to chemicals, epoxy resins are a popular choice for CWC coatings.

- Polyurethane Coatings These provide flexibility and enhanced abrasion resistance, making them suitable for environments subject to physical wear.

- Fusible Liners These coatings offer a unique method of protection by allowing the coating to bond directly to the pipe surface without the need for adhesives.

Conclusion

CWC pipe coating is an essential technology that plays a crucial role in extending the life and maintaining the integrity of pipeline systems across various industries. With benefits that range from corrosion resistance to environmental sustainability, it stands as a testament to the importance of innovative solutions in the face of increasing industrial challenges. As industries continue to advance, the adoption of reliable coatings like CWC will undoubtedly remain a priority for ensuring safe and efficient operations.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

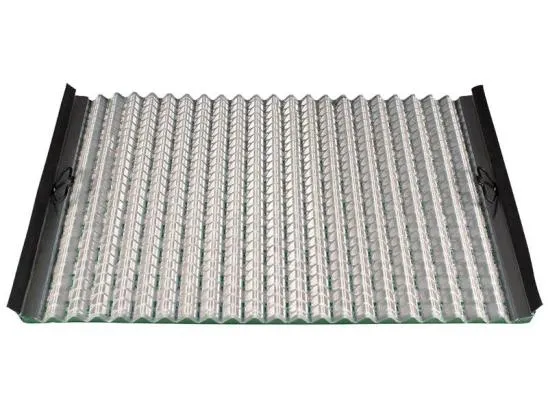

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025