- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Mesh Coating for Concrete Weight on Pipelines and Its Applications

Understanding Concrete Weight Coating for Pipeline Protection

Concrete weight coating is a crucial technique employed in the construction and maintenance of pipelines, particularly in underwater and offshore applications. This method involves encasing pipes in a thick layer of concrete, which serves multiple essential functions, including weight stabilization, corrosion protection, and impact resistance. As industries increasingly recognize the importance of robust pipeline infrastructure, the application of concrete weight coatings continues to gain popularity.

The Importance of Concrete Weight Coating

One of the primary reasons pipelines, especially those laid in shallow waters or submerged, require concrete weight coating is to prevent buoyancy. Without additional weight, pipelines tend to float, which can lead to significant structural instability. The concrete coating ensures that the pipe remains submerged and secured to the seabed, reducing the risk of displacement due to currents or other environmental factors.

Furthermore, concrete weight coatings provide excellent protection against external corrosion. When pipes are placed in harsh environments, such as saltwater or acidic soils, they become susceptible to degradation over time. The concrete layer acts as a barrier, shielding the pipe material from corrosive agents. Moreover, modern coatings can be enhanced with corrosion inhibitors, providing an additional layer of defense.

The Manufacturing Process

The manufacturing process of concrete weight-coated pipes typically involves several steps. First, a pipe made of carbon steel or another suitable material is prepared. The surface of the pipe is cleaned, often using sandblasting, to ensure proper adhesion of the concrete layer.

After preparation, a bonding layer, usually a specialized polymer, is applied to the pipe surface. This bonding layer enhances the adherence of the concrete to the pipe, ensuring longevity and effectiveness.

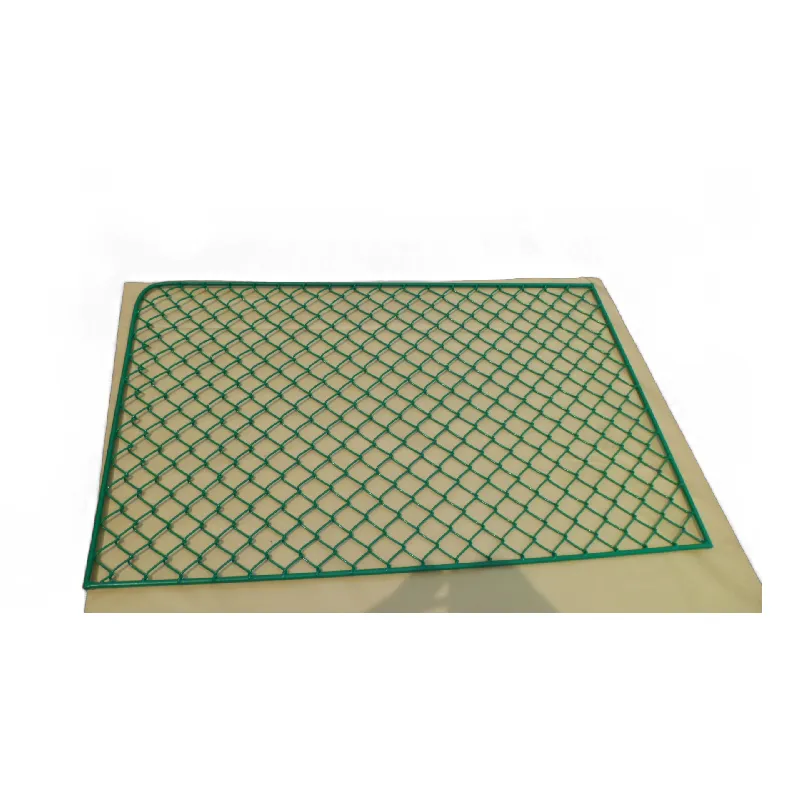

concrete weight coating pipe mesh

Next, the concrete is mixed to form a thick slurry that can be easily applied to the pipe. This mixture often contains aggregates that add weight and enhance strength. Once the concrete is mixed, it is uniformly applied onto the pipe in layers. The thickness of the concrete coating can be adjusted according to the specific requirements of the project.

After applying the concrete, the coated pipe is cured for a specific period to allow the concrete to set and achieve maximum strength. The fully cured pipe is then inspected for defects and tested for structural integrity. This meticulous process is vital to ensuring that the weights and protective qualities of the coating meet industry standards before the pipes are deployed in their intended environments.

Applications and Benefits

Concrete weight-coated pipes find numerous applications across various industries. They are predominantly used in the oil and gas sector for subsea pipelines, but their utility extends to freshwater pipelines, sewage systems, and offshore wind turbine installations. The advantages of using concrete weight coatings are manifold—they not only enhance the lifespan of the pipeline but also reduce maintenance costs over time.

In addition to their protective features, concrete-coated pipes are often more cost-effective compared to alternative methods of stabilization. The longevity and durability they offer translate into lower long-term expenses, making them an attractive option for many projects.

Conclusion

In summary, concrete weight coating is a beneficial and necessary technique for the protection and stabilization of pipelines in challenging environments. By ensuring that pipes are adequately weighted and protected from corrosion, this method enhances the safety and reliability of pipeline systems. As technologies advance and industries continue to innovate, the methods surrounding concrete weight coating will likely evolve, further improving efficiencies and outcomes in pipeline construction and maintenance. Investing in such robust solutions will be crucial as the demand for reliable and durable infrastructure continues to rise in an ever-changing industrial landscape.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025