- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Development of Mesh Coatings for Enhanced Concrete Weight Coating on Pipelines

Understanding Concrete Weight Coating for Pipeline Infrastructure

In the realm of pipeline infrastructure, particularly in the transportation of oil and gas, concrete weight coating (CWC) serves a critical purpose. This specialized coating is applied to pipelines to provide additional weight and stability, ensuring that they remain submerged in various aquatic environments and resist buoyancy forces. The utilization of concrete weight coatings has become a standard practice in the industry, and understanding its composition, application, and benefits is essential for professionals involved in pipeline construction and maintenance.

What is Concrete Weight Coating?

Concrete weight coating is a protective layer of concrete that is applied to the exterior of steel pipelines. The primary goal of CWC is to provide sufficient weight to prevent pipelines from floating when submerged underwater. This is particularly important in deep-water offshore environments, where buoyancy can pose a significant risk to pipeline integrity. The coating is typically comprised of a mixture of concrete, aggregates, and admixtures, giving it the necessary density and durability.

Application Process

The application of concrete weight coatings involves several critical steps. Initially, the steel pipes are cleaned and prepared to ensure proper adhesion of the coating material. Cleaning may involve abrasive blasting or other methods to remove contaminants like oil, dirt, and rust. Following preparation, a primer may be applied to enhance adhesion further.

Next, the concrete is typically applied using a specialized process. This can involve rotating the pipe as it passes through a concrete coating facility, where the concrete is sprayed or applied in layers. Controlled thickness is crucial, as the weight and stability of the final product depend on it. After the application, the coated pipes undergo curing to ensure that the concrete sets properly and achieves its desired mechanical properties.

Benefits of Concrete Weight Coating

1. Buoyancy Control One of the most significant benefits of concrete weight coating is its ability to mitigate buoyancy. By adding weight to the pipeline, CWC keeps it submerged, preventing movement caused by tides, currents, or other external forces.

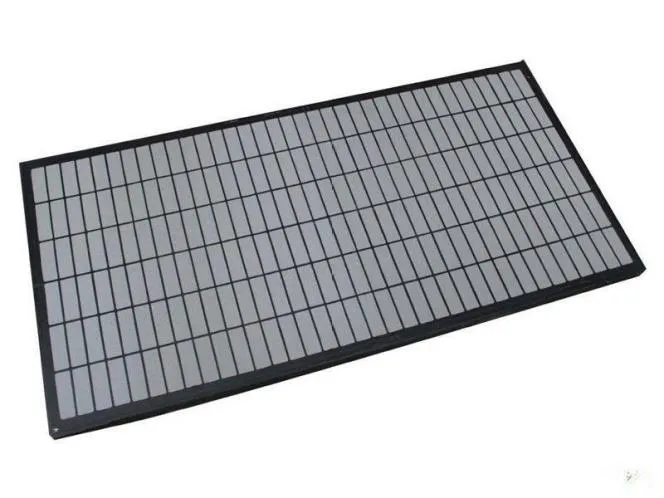

concrete weight coating pipe mesh

2. Mechanical Protection The concrete layer offers excellent mechanical protection against external impacts, abrasions, and environmental factors. This is particularly beneficial in harsh maritime environments, where pipelines may be exposed to debris and other potential threats.

3. Long-lasting Durability Concrete is inherently resistant to various environmental conditions, weathering, and chemical exposure. This longevity helps reduce maintenance and repair costs over time.

4. Cost-Effectiveness Although the initial investment for concrete weight coatings may be higher than other protective coatings, their durability and reduced need for maintenance can lead to significant cost savings in the long run.

5. Enhanced Stability The additional weight not only keeps the pipeline submerged but also enhances its stability during installation. This stability is crucial during the laying of pipelines in challenging underwater terrains.

Innovations and Advancements

The field of concrete weight coating is continuously evolving. Recent advancements include the development of eco-friendly concrete mixtures that reduce the environmental impact of pipeline construction. Additionally, innovations in the application processes have led to more efficient methods that improve production rates and reduce labor costs.

Furthermore, researchers are exploring the integration of sensors within the concrete layer. This technology could allow for real-time monitoring of stress, temperature, and environmental conditions, drastically improving maintenance protocols and pipeline safety.

Conclusion

Concrete weight coating is an invaluable component of modern pipeline infrastructure, particularly in offshore and challenging environments. By providing weight, protection, and stability, CWC ensures that pipelines remain functional, safe, and efficient over their lifespans. As the industry continues to innovate, concrete weight coatings will undoubtedly adapt, fostering even greater improvements in pipeline technology and infrastructure reliability. Understanding and implementing CWC effectively is paramount for engineers and professionals dedicated to the safe transportation of vital energy resources across the globe.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025