- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

concrete weight coating pipe

Understanding Concrete Weight Coating for Pipeline Applications

Concrete weight coating (CWC) plays a crucial role in the construction and installation of subsea pipelines. As the demand for energy resources increases, the need for efficient and reliable pipeline systems becomes more pressing. CWC provides essential benefits that enhance the performance and stability of pipelines laid in marine environments. This article delves into the purpose, applications, and advantages of concrete weight coating for pipelines.

What is Concrete Weight Coating?

Concrete weight coating involves the application of a layer of concrete around the steel pipe used in underwater pipelines. This process is often performed during the manufacturing stage or at specialized coating facilities. The concrete acts as a ballast, providing necessary weight to the pipeline, which is critical for stabilization and protection against environmental forces.

Why is Concrete Weight Coating Necessary?

1. Buoyancy Control Underwater pipelines tend to buoy due to their inherent buoyancy, especially with the presence of water. CWC ensures that the pipeline remains submerged and in contact with the seabed. This is essential for preventing floating, which can lead to significant structural and operational issues.

2. Protection Against External Forces The seabed is not a stable environment; it is subject to shifting currents, underwater landslides, and sediment movement. The weight from the concrete coating stabilizes the pipeline, protecting it from these external disturbances. This safeguarding helps to prolong the life of the pipeline, reducing maintenance and unexpected repair costs.

3. Prevention of Corrosion While the steel pipes in themselves are usually coated with anti-corrosive materials, the additional concrete layer offers another barrier against physical and chemical assaults from the environment. The combination of durable weights and protective coatings provides a multi-layer defense system for the pipeline.

Applications of Concrete Weight Coating

CWC is primarily used in offshore oil and gas pipelines but is also applicable in underwater cable installations and water supply lines. The procedures may vary depending on the project’s specifications and the environmental conditions of the installation site.

1. Oil and Gas Industries Offshore pipelines transporting oil and gas require reliable and durable solutions. CWC helps ensure that these pipelines remain secured to the seabed, managing risks associated with ocean currents and marine life.

concrete weight coating pipe

2. Telecommunication Cables For submarine telecommunications, CWC protects cables against marine growth and potential damage from fishing activities or shipping.

3. Infrastructure Projects Projects involving underwater tunnels or structures may also benefit from CWC, helping to secure these infrastructures against environmental variables.

Advantages of Concrete Weight Coating

The incorporation of concrete weight coating offers numerous advantages to pipeline projects

1. Cost-Effectiveness Although the initial cost of concrete weight coating can be significant, the long-term savings realized through reduced maintenance and the lifespan extension of the pipeline can be substantial.

2. Enhanced Safety A stable underwater pipeline reduces the likelihood of leaks or ruptures, ensuring safety for marine ecosystems as well as human operators involved in the energy sector.

3. Customizability Concrete weight coating can be tailored to meet specific project requirements, including varying thickness and weight levels depending on the pipeline’s intended environmental conditions.

4. Environmental Protection By enhancing structural integrity, CWC helps mitigate environmental risks associated with underwater pipelines, aligning with modern environmental standards and regulations.

Conclusion

In summary, concrete weight coating is an indispensable technique in the pipeline engineering field, particularly for offshore applications. By providing necessary ballast to counteract buoyancy, protecting against damaging external forces, and extending the life of the pipelines, CWC is critical for the safe and efficient transport of resources. As industries continue to evolve and seek new energy sources, the role of concrete weight coating will undoubtedly remain significant in maintaining the integrity and reliability of underwater pipeline systems.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

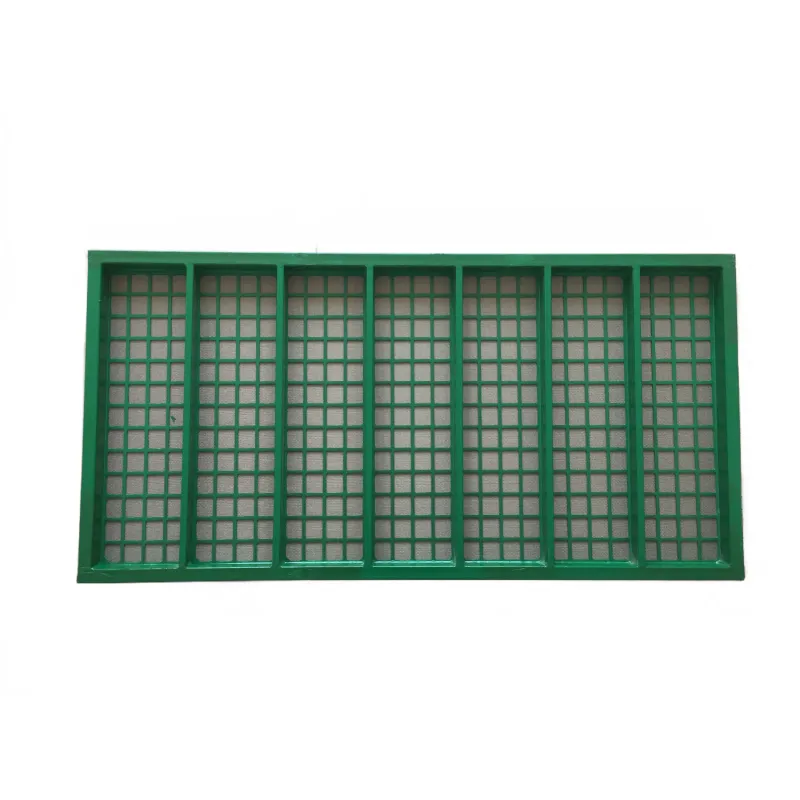

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025