- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Weighty Concrete Coating Solutions for Enhanced Protection and Durability in Marine Environments

Understanding Concrete Weight Coating Applications, Benefits, and Considerations

Concrete weight coating (CWC) is an essential process primarily used in the oil and gas industry, particularly for underwater pipelines and offshore structures. This unique technique involves the application of a substantial layer of concrete to pipes to ensure they remain submerged and stable in aquatic environments. The weight coating serves multiple purposes, from safeguarding pipelines against external pressures and facilitating their installation to enhancing corrosion protection.

What is Concrete Weight Coating?

Concrete weight coating refers to the process of applying a thick layer of concrete around pipes or other cylindrical structures to increase their weight. This added weight assists in keeping the pipes submerged in water, preventing buoyancy and the potential for movement caused by water currents or tidal forces. The coating usually consists of a concrete mixture formulated for durability, with additives that enhance its resilience against environmental stressors.

Applications of Concrete Weight Coating

The primary application of CWC is found in offshore pipeline installations. These pipelines transport hydrocarbons from underwater extraction points to processing facilities onshore. The weight coating is crucial in ensuring that these pipelines do not float or shift position, which could result in catastrophic leaks or structural failures.

Besides the oil and gas sector, concrete weight coating is also utilized in other industries, such as telecommunications, where submarine cables need protection against underwater stress. Additionally, it can be applied to various underwater structures, including moorings, anchors, and offshore wind farm bases, to provide stability in challenging marine conditions.

Benefits of Concrete Weight Coating

1. Stability and Submergence The primary benefit of concrete weight coating is the increased stability it provides for underwater installations. The heavy layer of concrete prevents pipelines from floating to the surface, ensuring they remain securely buried under sediment.

2. Corrosion Protection Beyond providing weight, concrete coatings can also offer a layer of protection against corrosion—a significant concern for any metal structure submerged in seawater. When properly mixed and cured, concrete can withstand the harsh conditions of the marine environment, prolonging the life of the underlying pipeline.

concrete weight coating

3. Ease of Installation Using CWC simplifies the installation process. The added weight of the concrete allows for transportation and laying of the pipes without requiring additional ballast materials, streamlining logistics and reducing overall costs.

4. Durability Concrete-coated pipes can withstand impacts from debris, marine life, and tools used during installation. This durability is especially crucial in high-traffic shipping lanes and turbulent waters.

5. Thermal Insulation In some cases, concrete weight coating provides thermal insulation, minimizing heat loss from hot fluids (such as oil) transported through the pipeline. This can be particularly beneficial in cold marine environments, maintaining the efficiency of the transport process.

Considerations in Concrete Weight Coating

While the benefits of concrete weight coating are substantial, there are also several considerations to keep in mind during the process

- Weight of the Coating The weight of the concrete must be carefully calculated to avoid exceeding the load-bearing capacity of the supporting structures during transportation and installation. - Production Costs The process of applying concrete weight coating can be cost-intensive, requiring specialized equipment and skilled labor for both the coating application and subsequent quality inspection.

- Environmental Impact As with any industrial process, environmental considerations must be taken into account. Proper handling and disposal of materials and ensuring that no harmful substances leach into the ocean are essential for minimizing ecological impact.

- Regulatory Compliance CWC applications must often adhere to strict industry regulations to ensure safety and environmental protection, necessitating thorough planning and execution to align with compliance standards.

Conclusion

Concrete weight coating plays a pivotal role in the safe, efficient, and effective installation of underwater pipelines and structures. By providing the necessary weight to prevent buoyancy, offering corrosion protection, and enhancing durability, CWC is integral to the success of offshore projects. As technology advances and environmental considerations gain prominence, the applications and methodologies surrounding concrete weight coating will continue to evolve, maintaining its vital role in the marine infrastructure landscape.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

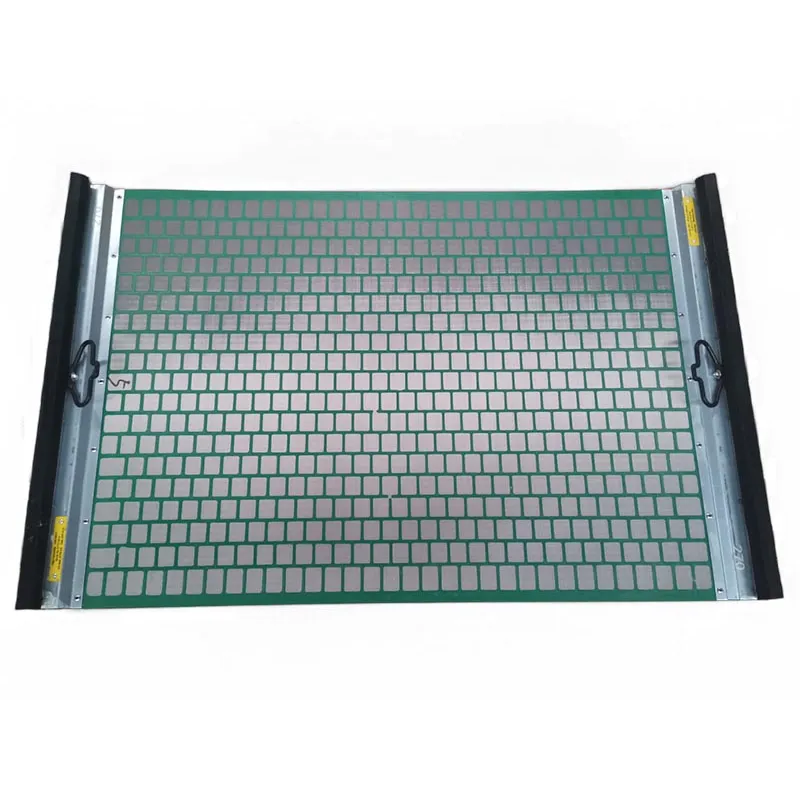

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025