- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

concrete weight coating

Concrete Weight Coating An Essential Solution for Subsea Pipelines

The world of subsea engineering faces numerous challenges, one of the most significant being the stability and protection of pipelines that transport oil, gas, and other essential materials beneath the ocean floor. To ensure the safety and integrity of these pipelines, engineers have developed various protective measures, one of which is concrete weight coating (CWC). This innovative solution serves multiple purposes, including providing ballast, protection from external damage, and thermal insulation, thus ensuring the operational efficiency and longevity of subsea pipelines.

What is Concrete Weight Coating?

Concrete weight coating is a specialized application used predominantly on pipes intended for underwater installation. It involves encasing the outer surface of the pipeline with a layer of concrete, thereby enhancing its weight and stability. The primary objectives of this coating are to prevent buoyancy, provide external protection against mechanical damage, and safeguard against environmental conditions such as corrosion and marine growth.

The Importance of Ballast

One of the principal functions of concrete weight coating is to provide adequate ballast to the pipeline. Generally, pipelines are buoyant, particularly when submerged in water. If left uncoated, these pipelines may float, causing problems during installation and potentially leading to misalignment or even catastrophic failure. By applying the concrete weight coating, the pipeline gains sufficient weight to ensure it remains in a fixed position on the seabed. This stability is essential for proper installation and operational functionality.

Protection Against External Damage

Subsea pipelines are vulnerable to various external threats, including environmental factors, fishing activities, and interactions with marine life. The concrete weight coating acts as a robust protective barrier, shielding the pipeline from potential impacts and abrasions. This external layer can withstand harsh underwater conditions, thereby minimizing the risk of leaks or ruptures that could have devastating environmental and economic consequences. The durability of the coating is crucial, especially in high-traffic areas where fishing vessels and other marine activities are prevalent.

concrete weight coating

Insulation Properties

Another critical aspect of concrete weight coating is its thermal insulation properties. Pipelines transporting hydrocarbons may experience significant temperature fluctuations, which can lead to condensation and corrosion if not adequately managed. The concrete layer helps to insulate the pipeline, reducing the risk of temperature-related issues and maintaining the thermal stability of the transported materials. This insulation is particularly important for materials that could become viscous or solidify at lower temperatures, ensuring the uninterrupted flow of resources.

Environmental Considerations

As with any engineering solution, the use of concrete weight coating must be approached with environmental considerations in mind. The materials used in the coating process must be carefully selected to minimize ecological impact. Moreover, the application technique should be designed to limit any disturbances to the marine environment, ensuring that ecosystems are preserved during pipeline installation and maintenance.

The Future of Concrete Weight Coating

As technology and engineering practices continue to evolve, so too does the implementation of concrete weight coating. Researchers are exploring innovative materials and methods to enhance the performance and sustainability of CWC. For instance, the integration of recycled materials into the concrete mix is being studied to reduce the environmental footprint of the coating process. Additionally, advancements in monitoring technology may allow for real-time assessments of the integrity and performance of coated pipelines, further improving safety and efficiency.

Conclusion

Concrete weight coating is a vital element in the subsea pipeline industry, providing essential ballast, protection, and insulation for underwater installations. Its role in ensuring the stability and safety of pipeline operations cannot be overstated. As the demands of the oil and gas industry grow, so too will the need for effective protective measures such as concrete weight coating. By continuing to innovate and improve these solutions, we can help safeguard our natural resources while minimizing the environmental impact of subsea operations. In a world where the responsible management of resources is increasingly critical, concrete weight coating stands as a testament to the ingenuity and dedication of engineers striving to build a sustainable future.

-

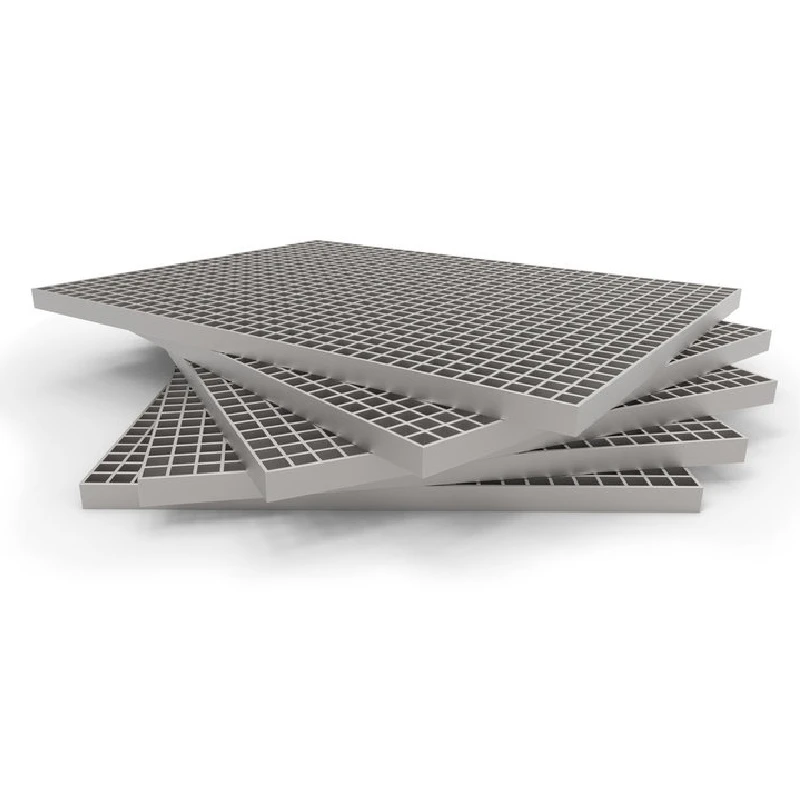

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025