- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

concrete weight coating

Understanding Concrete Weight Coating An Essential Component in Pipeline Protection

Concrete weight coating (CWC) is a widely used method in the oil and gas industry, particularly in the installation and protection of pipelines that are laid on the seabed or underwater. This robust protective layer serves multiple purposes, enhancing the longevity and stability of pipelines in various environmental conditions. In this article, we will explore the significance of concrete weight coatings, their application processes, and the benefits they offer in pipeline engineering.

What is Concrete Weight Coating?

Concrete weight coating involves applying a dense concrete layer to the exterior of a coated pipeline. The primary purpose of this coating is to provide the necessary weight to suppress buoyancy forces when pipes are submerged in water, ensuring they remain securely positioned on the seabed. In addition to its weight-providing capabilities, the concrete layer acts as a shield against external physical damage, environmental conditions, and marine organisms, thereby protecting the pipeline's integrity.

Importance of Concrete Weight Coating

1. Pipe Stability and Buoyancy Control One of the most critical roles of concrete weight coating is to counteract the natural buoyancy of submerged pipes. Pipelines that are not adequately weighted can float to the surface, leading to potential damage during installation or operational phases. CWC ensures that pipes stay in position, reducing the risk of displacement due to ocean currents or shifting seabed conditions.

2. Structural Protection Beyond its primary function of stabilizing pipelines, CWC provides a protective barrier against mechanical hazards. Rocks, debris, and environmental impacts can cause significant damage to exposed pipelines. Concrete coatings absorb and dissipate impact energy, thus safeguarding the pipeline from crushing or abrasion.

3. Corrosion Resistance While concrete itself is not a corrosion-resistant material, it can be combined with other protective coatings to enhance its performance. The application of epoxy or other anticorrosive materials beneath the concrete layer offers added protection against electrochemical reactions that may occur in marine environments, thus prolonging the pipeline’s service life.

4. Thermal Protection For certain applications, such as those involving the transportation of hot fluids, concrete weight coatings can also provide a degree of thermal insulation. This feature helps in maintaining the fluid temperature and minimizing heat loss or gain, which is crucial for operational efficiency.

concrete weight coating

Application Process of Concrete Weight Coating

The process of applying concrete weight coating typically involves several steps

1. Pipe Preparation Before the concrete can be applied, the pipeline is thoroughly cleaned and coated with a layer of protective paint or adhesive that promotes bonding with the concrete.

2. Concrete Mixing A specific concrete mix is designed to achieve the desired density and strength. This often includes additives that enhance water resistance and overall durability.

3. Application The prepared pipes are taken to a coating facility where concrete is applied using various techniques, including centrifugal casting or spraying. The application must be uniform to ensure that the weight distribution is consistent along the length of the pipeline.

4. Curing After the concrete is applied, it needs to cure properly. This process involves allowing the concrete to harden and gain strength, which can take several days depending on environmental conditions.

5. Quality Control Finally, the coated pipelines undergo rigorous inspection to verify that the concrete has been uniformly applied and meets the specified thickness and weight standards.

Conclusion

Concrete weight coating plays a pivotal role in the integrity and stability of underwater pipelines. By providing necessary weight, structural protection, and additional benefits such as thermal insulation and corrosion resistance, CWC serves as an essential component in pipeline construction and maintenance. As the demand for offshore resources continues to grow, the relevance of concrete weight coating in safeguarding our energy infrastructure cannot be overstated. With advances in materials science and engineering practices, the future of CWC promises even greater durability and efficiency in pipeline protection, ensuring that the assets remain safe and operational in challenging underwater environments.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

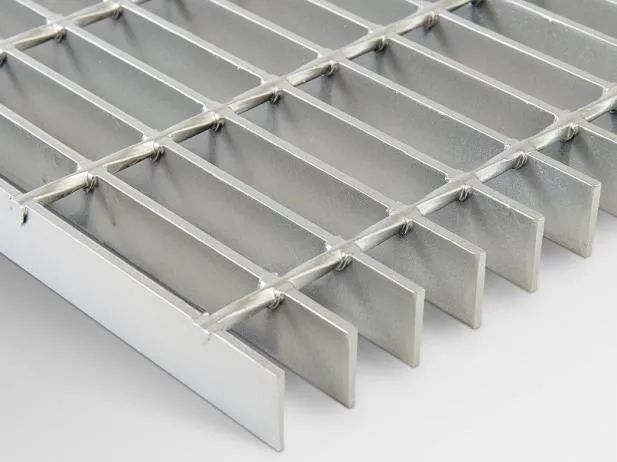

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025